Beef steak processing device of food processing

A processing device and food processing technology, which is applied in the fields of processing meat, food science, slaughtering, etc., can solve the problems of unsuitability for large-scale industrial production, poor fiber crushing effect, and large damage to human wrists. The effect of crushing and improving the taste of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

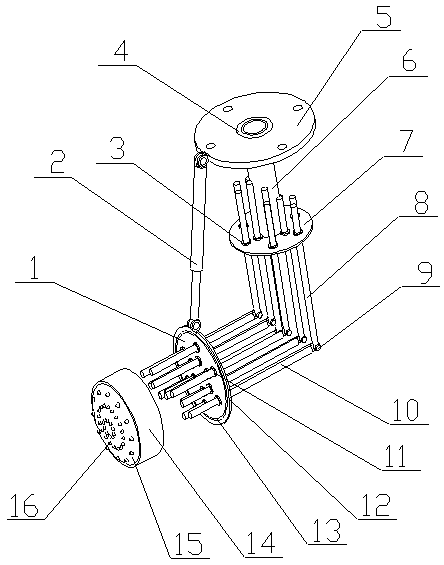

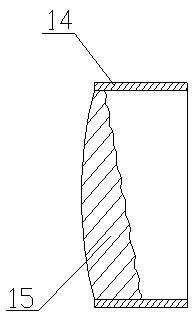

[0022] A steak processing device for food processing in the present invention is realized in this way. When in use, when the steak fibers are crushed, the fixing plate (5) is first installed and fixed in an appropriate position through a plurality of mounting holes on the fixing plate (5), Make the silicone pad (15) contact the surface of the steak, then connect the external motor with one end of the rotating cylinder (6), the external motor works to drive the rotating cylinder (6) to rotate, and the rotating cylinder (6) drives the driving disc (7) to rotate , the active plate (7) drives multiple active rods (8) to rotate, and the multiple active rods (8) slide along the corresponding main sliding sleeves (3) during the rotation process, and the multiple active rods (8) respectively Drive the connected driven rods (10) to rotate, and multiple driven rods (10) drive the driven disc (1) to rotate in the fixed ring (12). During the rotation process, multiple driven rods (10) will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com