Pulse current repairing device for microcrack in metal pipe and pulse current repairing method for microcrack in metal pipe

A technology of metal pipe fittings and pulse current, applied in metal processing equipment, high frequency current welding equipment, welding equipment and other directions, can solve the problems of dangerous operation, poor contact, poor repair effect of metal pipe fittings, etc., to achieve efficient repair and improve repair efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

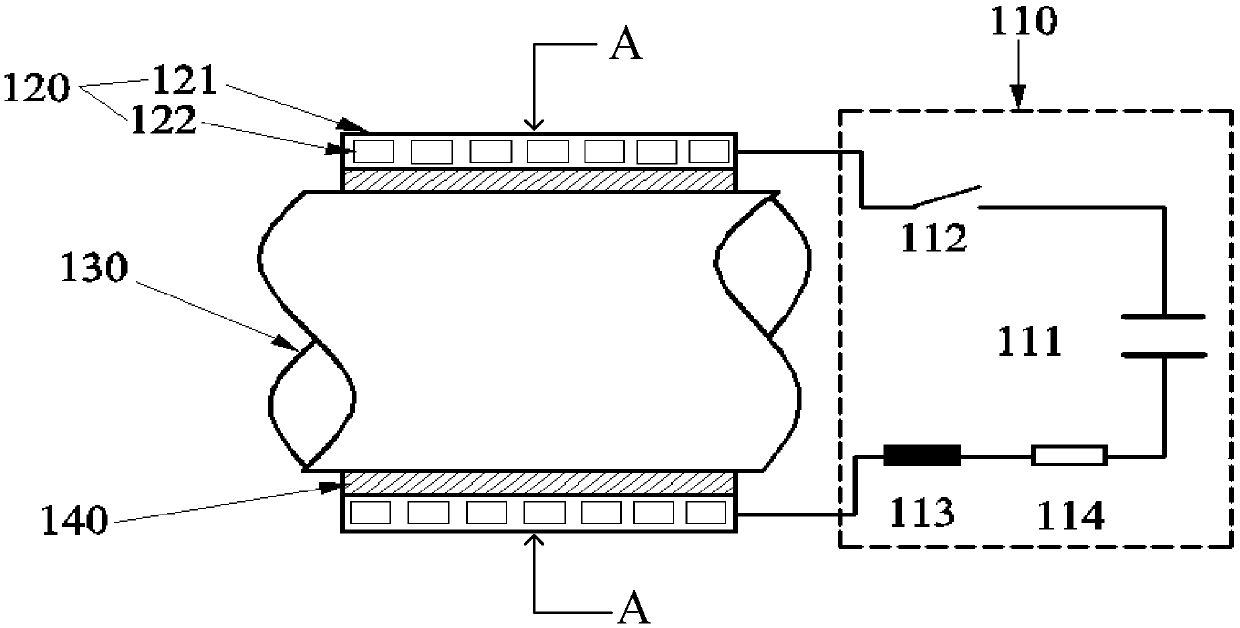

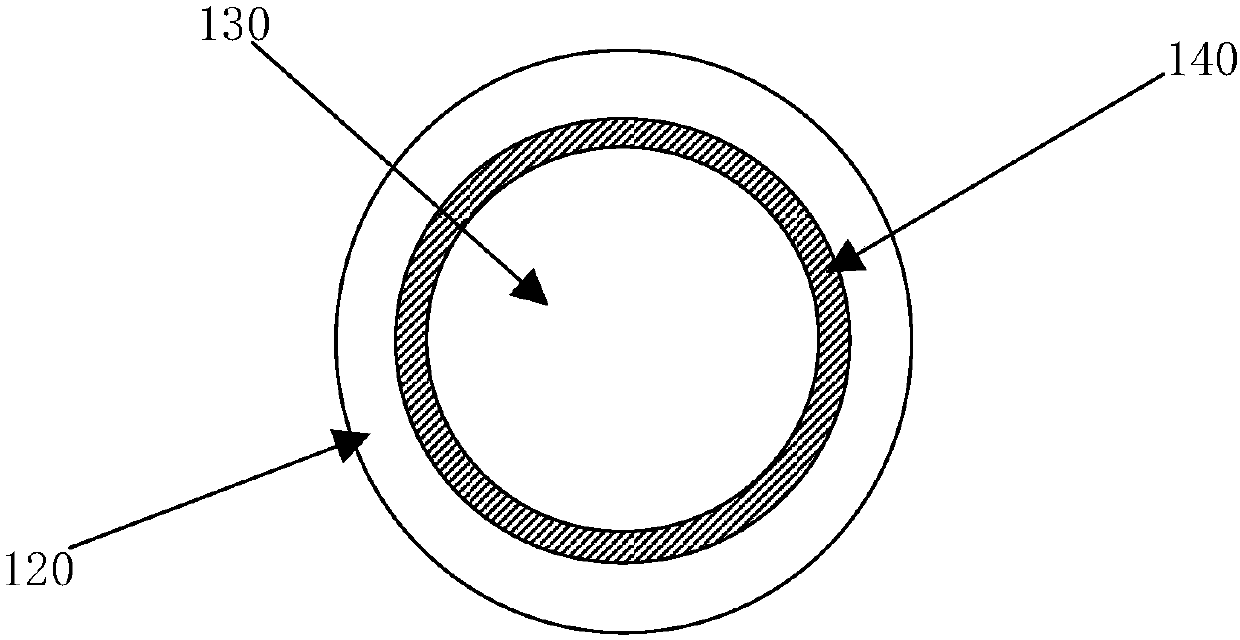

[0025] figure 1 A schematic structural diagram of a pulse current repairing device for microcracks in a metal pipe in Example 1 is shown. figure 2 shown figure 1 Sectional view of A-A in the middle. The device is used for arresting and repairing micro-cracks in metal pipe fittings. The device can be used for crack arrest and repair of magnesium alloy pipe fittings, stainless steel pipe fittings, titanium alloy pipe fittings, aluminum alloy pipe fittings, etc.

[0026] refer to figure 1 and figure 2 , taking the repairing of microcracks in magnesium alloy pipe fittings as an example to illustrate this embodiment, a device for arresting and repairing microcracks in metal pipe fittings in this embodiment includes a pulse power supply 110, a helical coil 120 and a fixed shaft 130,

[0027] The magnesium alloy pipe fitting is nested and attached to the outer surface of the fixed shaft 130 , and the helical coil 120 is nested and attached to the outer surface of the magnesium...

Embodiment 2

[0042] figure 1 A schematic structural diagram of a pulse current repairing device for microcracks in a metal pipe in Example 1 is shown. figure 2 shown figure 1 Sectional view of A-A in the middle. The device is used for arresting and repairing micro-cracks in metal pipe fittings. The device can be used for crack arrest and repair of magnesium alloy pipe fittings, stainless steel pipe fittings, titanium alloy pipe fittings, carbon steel pipe fittings, aluminum alloy pipe fittings, etc.

[0043] refer to figure 1 and figure 2 , taking the repairing of microcracks in magnesium alloy pipe fittings as an example to illustrate this embodiment, this embodiment is a pulse current repair method for microcracks in metal pipe fittings, which is based on a pulse current repair method for microcracks in metal pipe fittings To fix the device implementation, the method is:

[0044] The pulse power supply 110 discharges the helical coil 120 at a discharge voltage of 1KV ~ 20KV, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com