Ultrashort pulse laser processing equipment for hard and brittle materials

An ultra-short pulse laser, processing equipment technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of low processing precision and low quality, achieve high processing precision, optimize processing technology, installation and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

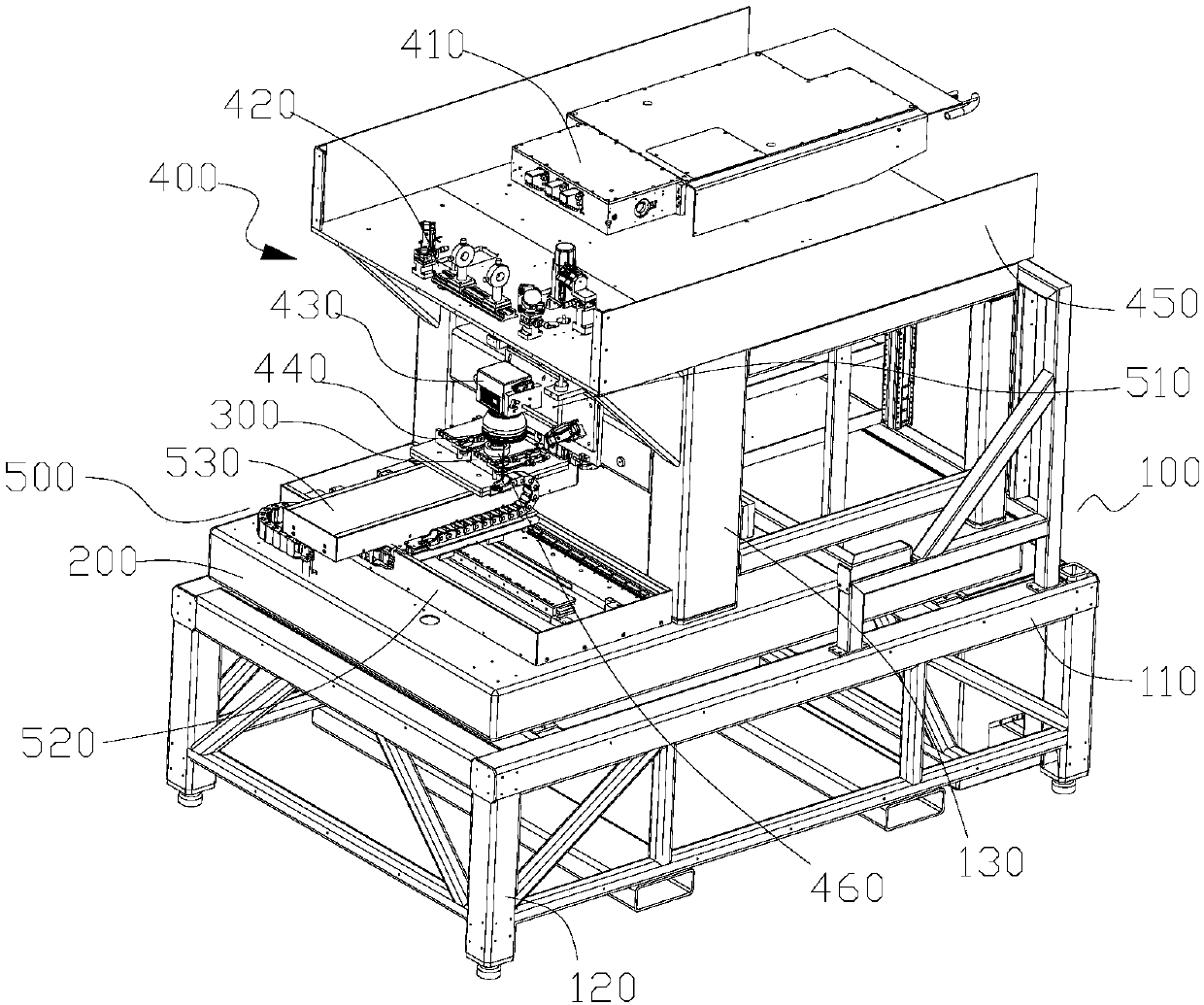

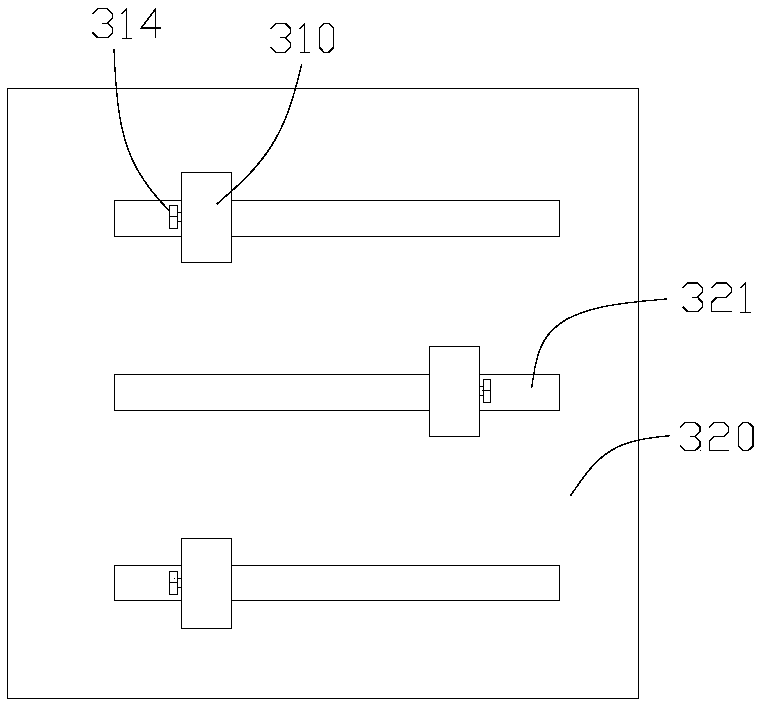

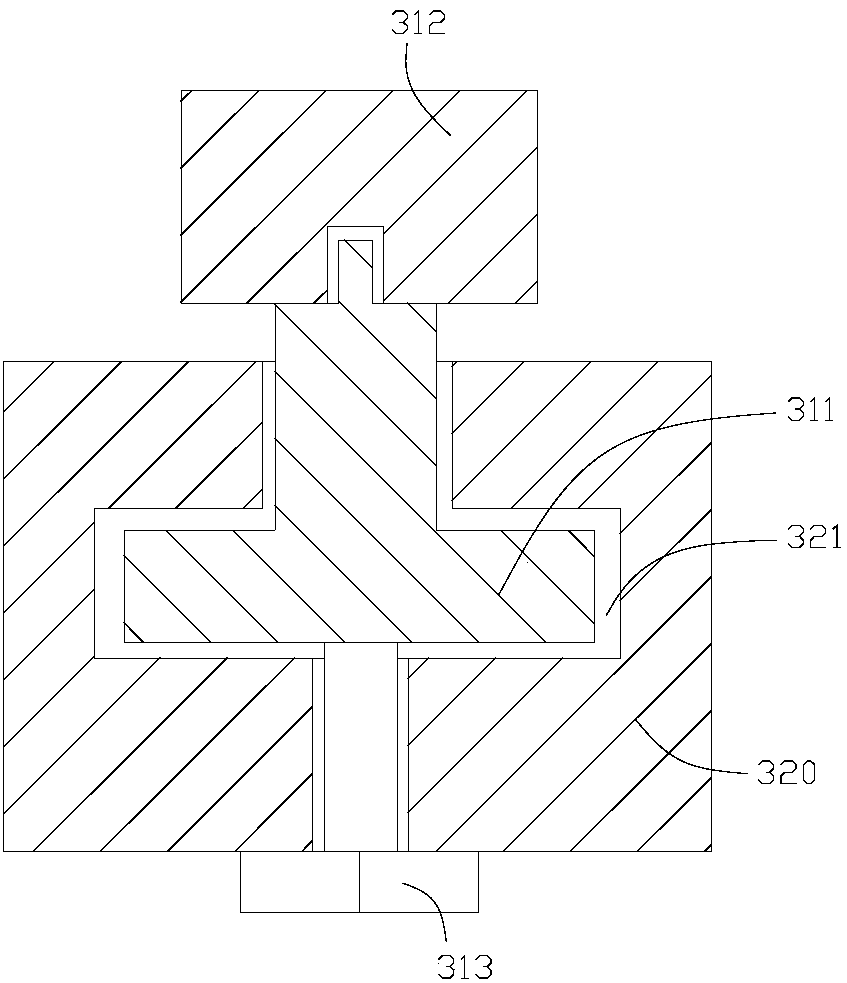

[0033] see figure 1 - Figure 4 , this embodiment provides an ultrashort pulse laser processing equipment for hard and brittle materials.

[0034] In this embodiment, the ultrashort pulse laser processing equipment includes a frame 100, a workbench 200, a fixture 300, an optical substrate 450, a laser component 400, a three-dimensional motion mechanism 500, and an electrical cabinet. Worktable 200 , optical substrate 450 and some components of laser assembly 400 are installed on frame 100 , fixture 300 and some components of laser assembly 400 are installed on three-dimensional movement mechanism 500 , and fixture 300 is installed on three-dimensional movement mechanism 500 .

[0035]The frame 100 provided in this embodiment includes a main frame body 110, support legs 120 and a gantry frame 130, the support legs 120 are installed on the bottom of the main frame body 110, and the number of support legs 120 is set as required to achieve stable support. Can. The gantry frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com