Precise digital printing method for fabric by utilizing digital printing machine and fabric

A digital printing machine, digital printing technology, applied in the field of printing and dyeing, can solve the problem of not being able to secondary processing and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Reference will now be made in detail to the embodiments depicted in the accompanying drawings. In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, it will be understood by those skilled in the art that the present invention may be practiced without these specific details.

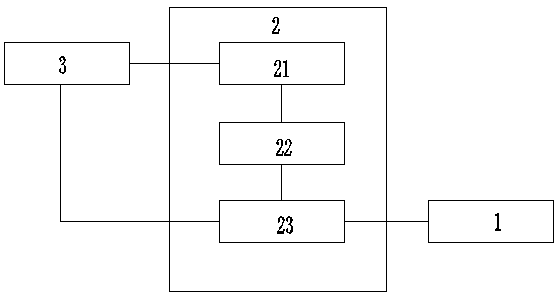

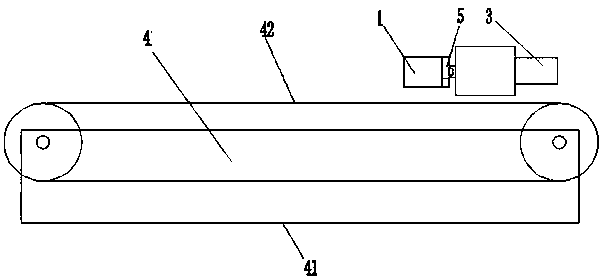

[0062] like figure 1 As shown, the digital inkjet printer in this embodiment includes a digital inkjet head 1 , a control system 2 , an image acquisition unit 3 and a material feeding device 4 . In addition, the digital jet printer also includes some peripheral interfaces, display screens and external ports, etc., which will not be described here. The various components shown in Figure 1 can be implemented in hardware, software, or a combination of hardware and software, including one or more signal processing and / or application-specific integrated circuits.

[0063] The digital print head 1 ...

Embodiment 2

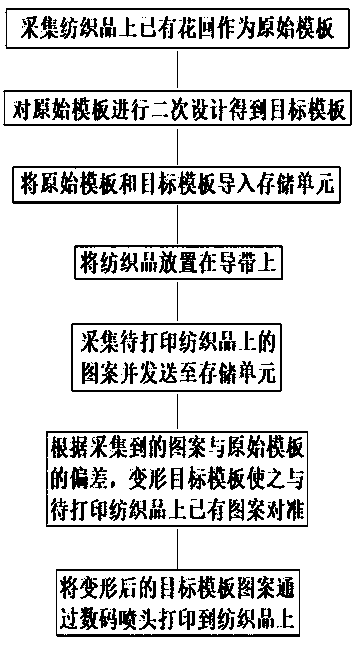

[0070] The printing method in the present embodiment, it adopts the digital jet printing machine among the embodiment 1, specifically comprises the following steps:

[0071] 1) Collect a floral pattern on the fabric as the original template;

[0072] 2) Perform a secondary design on the existing original template to obtain the target pattern template. The secondary design here can be processed on the existing pattern by computer or by hand. , after the collection in step 1, print out the pattern, and perform hand-painting processing on it, and after the processing is completed, collect again to obtain the target pattern template;

[0073] 3) importing the original template and the target pattern template into the storage unit 21 of the control system 2;

[0074] 4) Place the fabric flat and stick it on the guide belt 42 of the material feeding device 4;

[0075] 5) The image acquisition unit 3 acquires the pattern on the fabric, and the image acquired by the image acquisitio...

Embodiment 3

[0091] like Figure 4 to Figure 6 As shown, the fabric in this embodiment has a basic pattern 10 and a secondary design pattern 20, and the secondary design pattern 20 is formed by the printing method in the above-mentioned embodiment 2. image 3 Among them, it is the state when the secondary design pattern 20 is not set on the fabric. At this time, the fabric only has the basic pattern 10.

[0092] The basic pattern 10 in this embodiment is a lace pattern, a jacquard pattern, an embroidery pattern or a printing pattern.

[0093] The secondary design pattern 20 in this embodiment is a colored pattern of the basic pattern 10 , an overprinted pattern of the basic pattern or a combination of the above two. like Figure 4 as shown, Figure 4 For, design the sketch map of overprinting pattern on fabric base pattern 10; Figure 5 as shown, Figure 5 For, on the fabric, the basic pattern 10 is colored to obtain the colored pattern after the basic pattern 10 is colored; as Imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com