Air pressure booster assembly based on feedback disc structure

A technology of feedback disc and booster, which is applied in the direction of brakes, transportation and packaging, and brake transmission devices. It can solve the problems of brake pedal follow-up, poor braking feeling, and weak boosting effect, and achieve increased braking capacity. Large, good braking effect, and the effect of reducing the cost of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

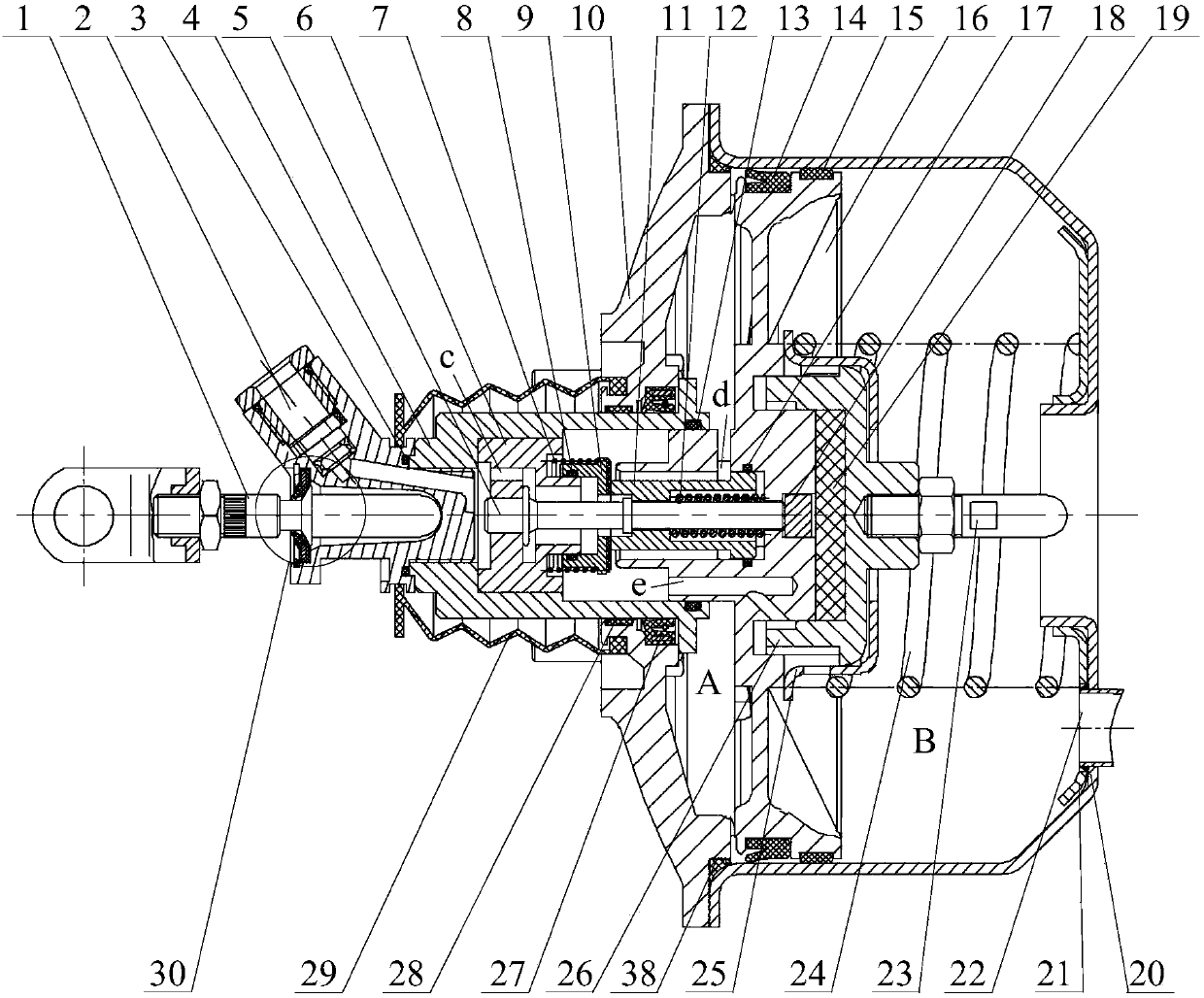

[0030] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

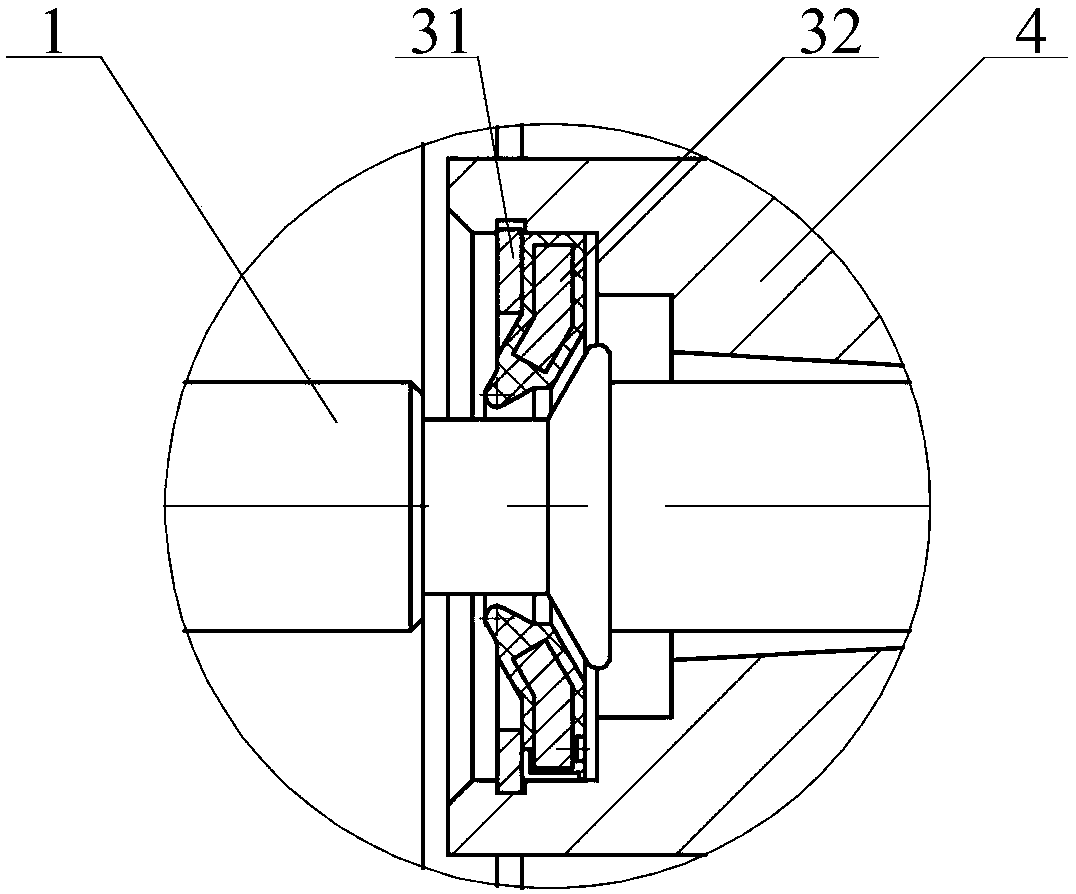

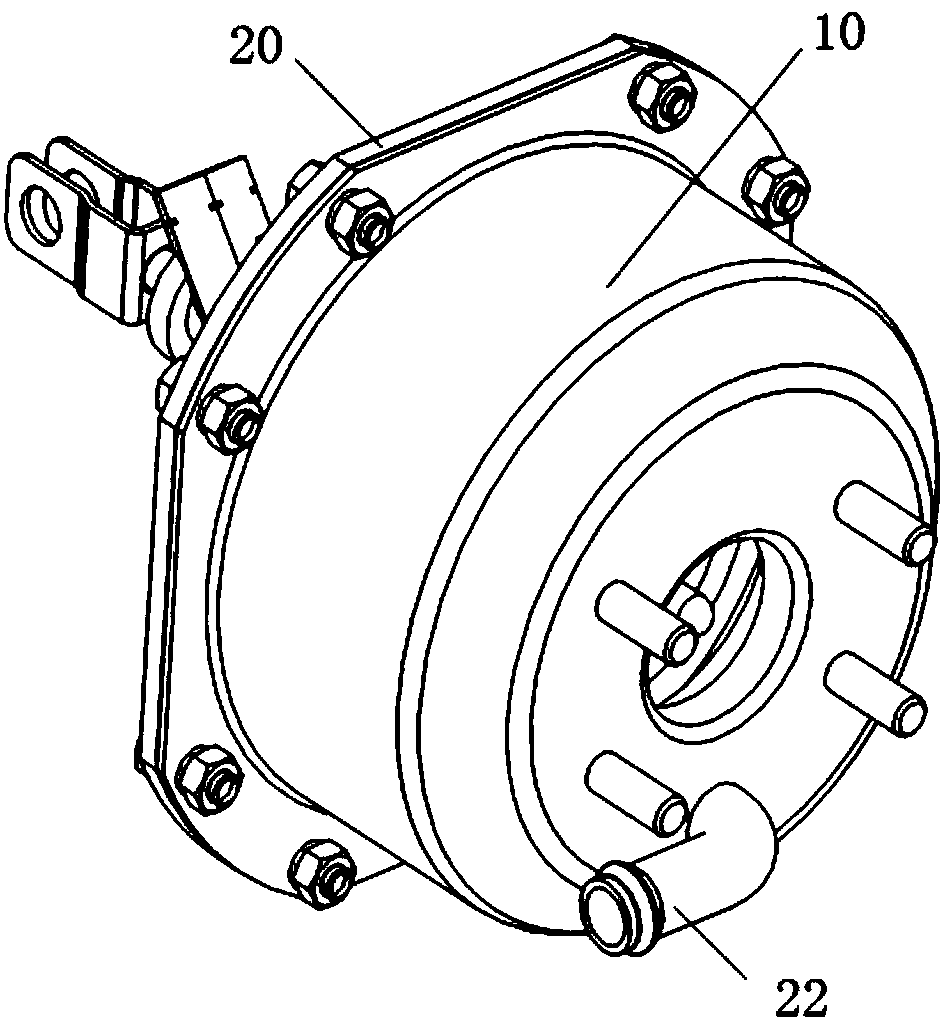

[0031] The pneumatic booster assembly based on the feedback disc structure is mainly composed of input force push rod 1, intake seat 2, guide sleeve 4, valve stem 5, valve stem seat 6, valve return spring 7, valve 9, rear housing 10, Lock block 11, guide sleeve return spring 12, booster piston seal 14, booster piston guide sleeve 15, booster piston 16, pressure block 18, feedback disc 19, front housing 20, reinforcement plate 21, exhaust port 22, output The force push rod 23, the piston return spring 24, the piston return spring seat 25, the output push rod seat 26, the valve seat guide sleeve 28, the dust cover 29, the input force push rod anti-drop mechanism 30 and the sealing ring are composed.

[0032] The air inlet seat 2 has a high-pressure air inlet, and the air inlet seat 2 is threadedly connected with the guide sleeve 4, and the sealing of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com