MEMS micro-thruster array chip with thrust range extending module

A micro-thrust, array chip technology, applied in the direction of space navigation aircraft, aircraft, jet propulsion, etc., can solve the problems of high cost, unfavorable mass production and serialization of products, long development cycle, etc., to enhance process flexibility and The effect of flexible performance, large specific impulse and high burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

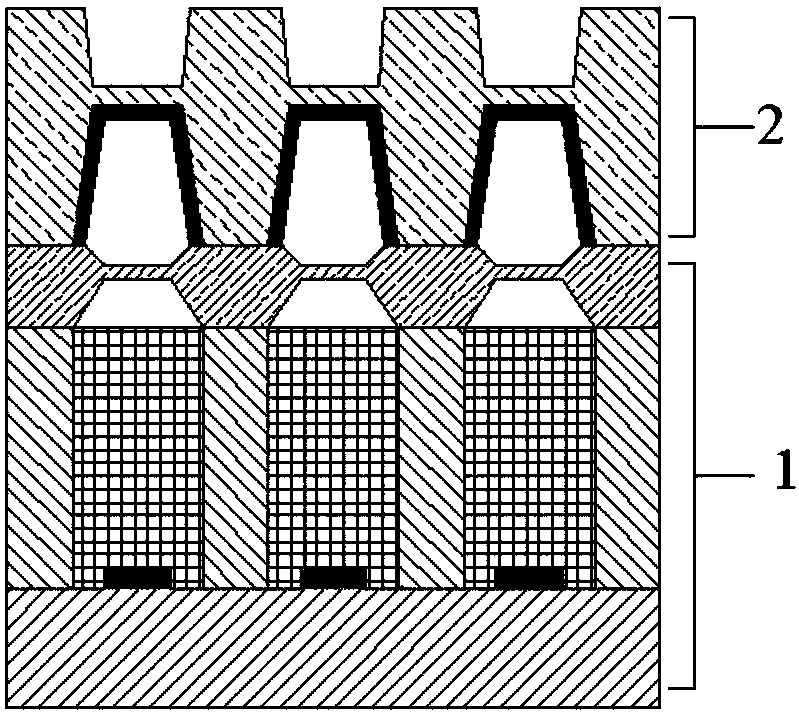

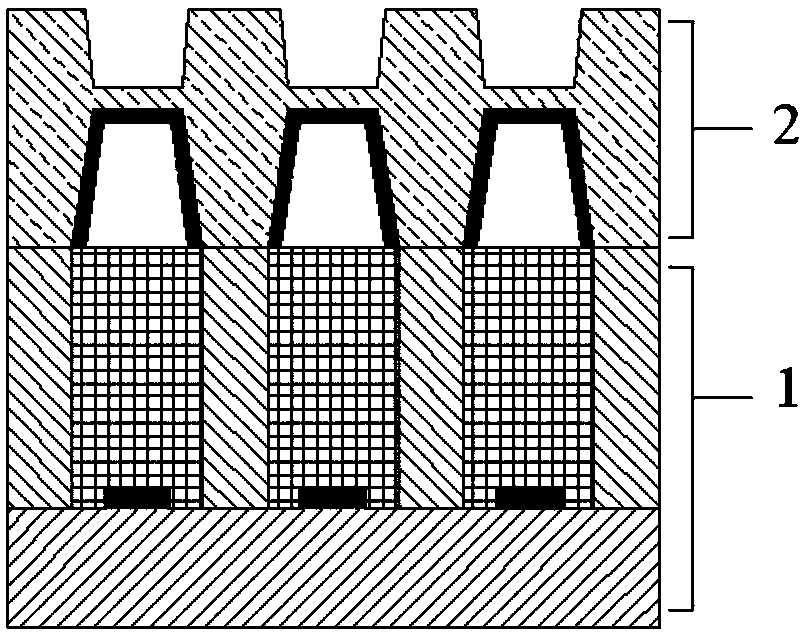

[0020] A MEMS micro-thruster array chip with a thrust range-extending module, including an ignition layer, a drug chamber layer, and a thrust-range-extending module arranged sequentially from bottom to top;

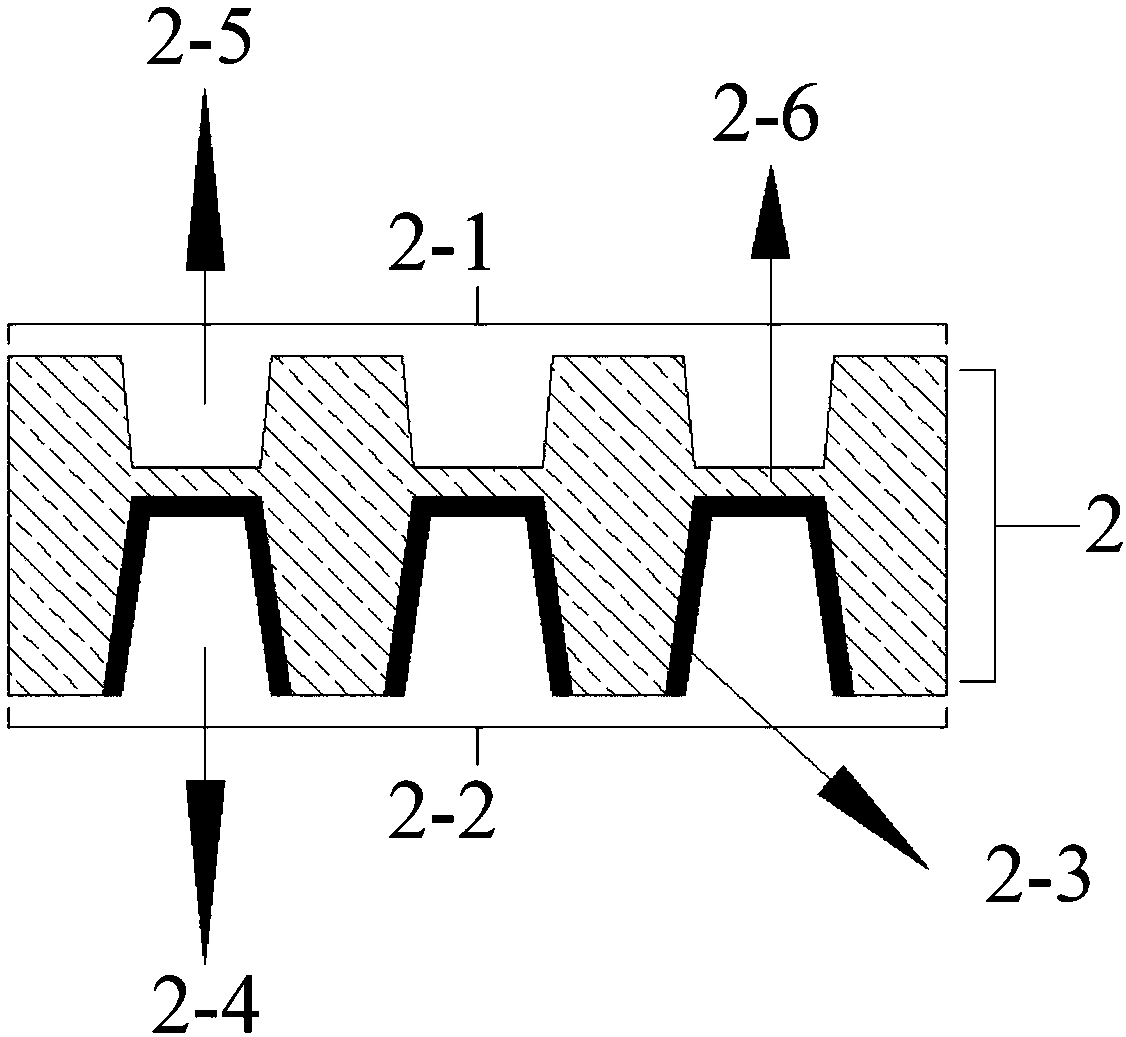

[0021] like figure 1 As shown, the upper surface 2-1 of the thrust range extender module is provided with an outer spray hole 2-5, and the lower surface 2-2 of the thrust range extender module is provided with an inner spray hole 2-4, and the inner spray hole 2-4 and A single crystal silicon thin film 2-6 is set between the outer nozzle holes 2-5 as a diaphragm between the inner and outer nozzle holes; the inner wall of the inner nozzle hole grows or deposits a high-energy nanometer energetic film 2-3 as a propellant for the thrust-range extension module . High energy nano energetic films include but not limited to new porous silicon nano energetic films, CuO nanowire / Al energetic films, Mg nanowires / PTFE, CuO / Al reactive multilayer films and other new integrable Nano e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com