Liquid pressure leakage detecting system for double-layer lining of underground oil tank of filling station

A liquid pressure and detection system technology, applied in the direction of containers, packaging, underwater structures, etc., can solve the problems of increasing construction difficulty and risk, increasing the risk of leakage, and low leak detection sensitivity, so as to achieve long-term continuous monitoring , good reliability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

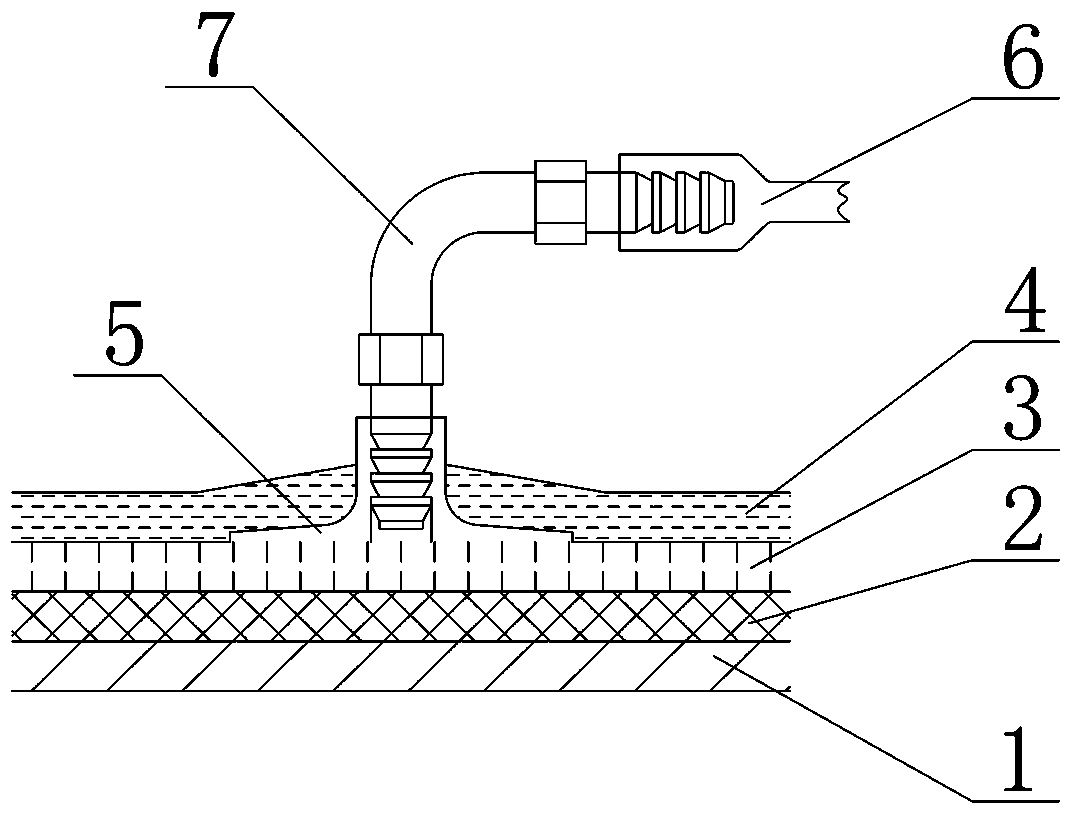

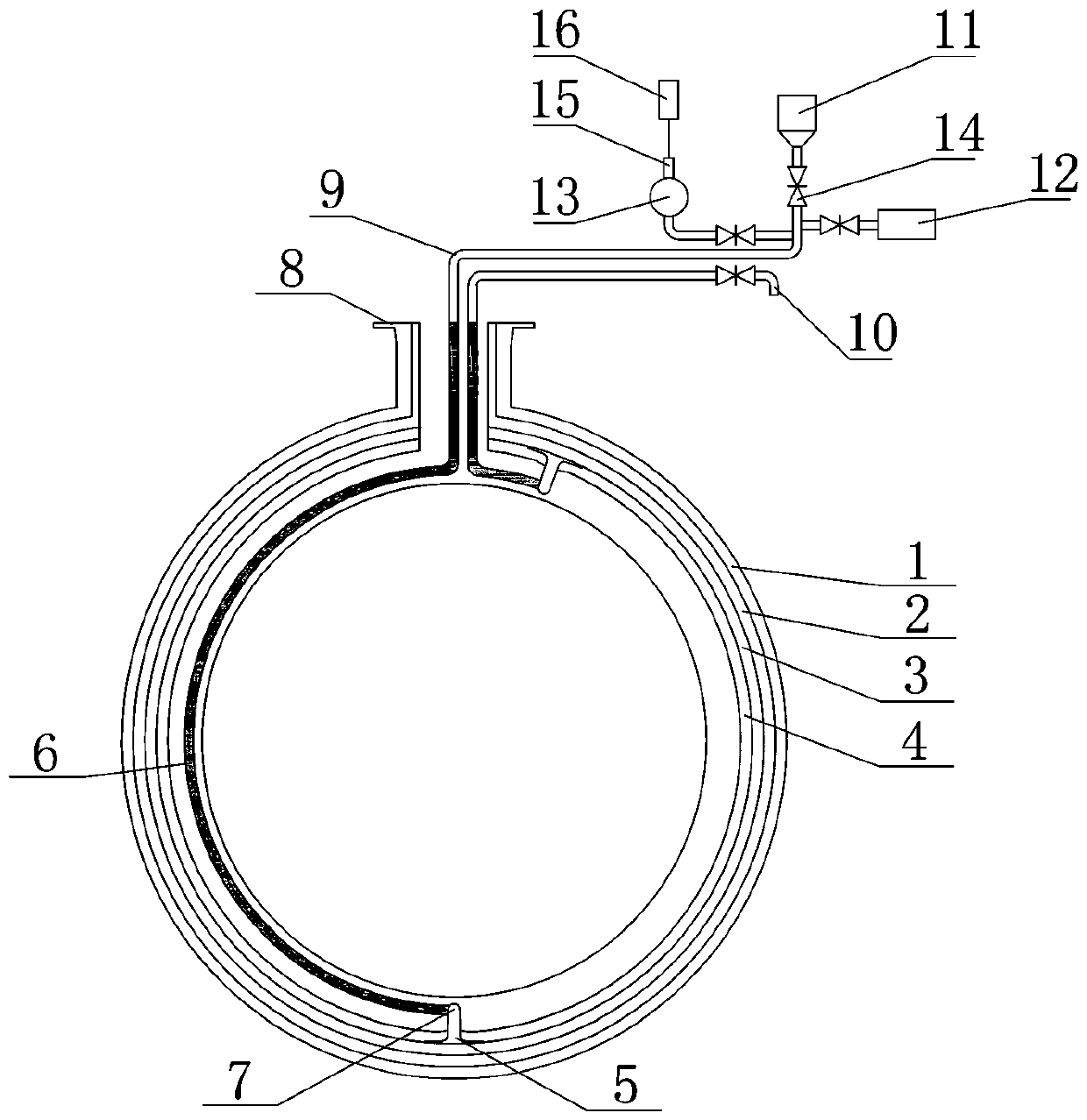

[0024] Below in conjunction with accompanying drawing and embodiment, the gas station buried oil tank double-layer liner liquid pressure leakage detection system of the present invention and its leakage detection method will be described in further detail, revealing the best implementation method of the present invention, is to make this field Those of ordinary skill can implement the present invention, but it should be noted that the present invention is by no means limited to the following embodiments. Based on the teachings of the present invention, any obvious transformation or equivalent replacement should also be considered as falling within the protection scope of the present invention.

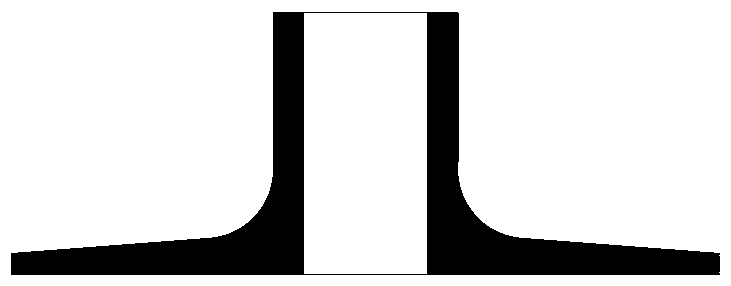

[0025] Oil tank double-layer lining liquid pressure leakage detection system ( image 3 , 4 ), including: the built-in double-layer glass fiber reinforced plastic lining of the buried oil tank, the fixed connection between the middle gap layer and the leak detection prefabricated part,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com