Surface adhesive sizing material for oil tank sealing tape adhesive tape

A sealing tape and cloth surface adhesive technology, which is applied in the field of oil tank sealing tape, can solve the problems of decreased cold resistance, prolonged scorch time, and increased Mooney viscosity, etc.

Inactive Publication Date: 2018-04-13

中国化工集团曙光橡胶工业研究设计院有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

⑤ The Mooney viscosity of the compound used in combination increases, the plasticity decreases, and the scorch time prolongs

⑥ Decreased cold resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

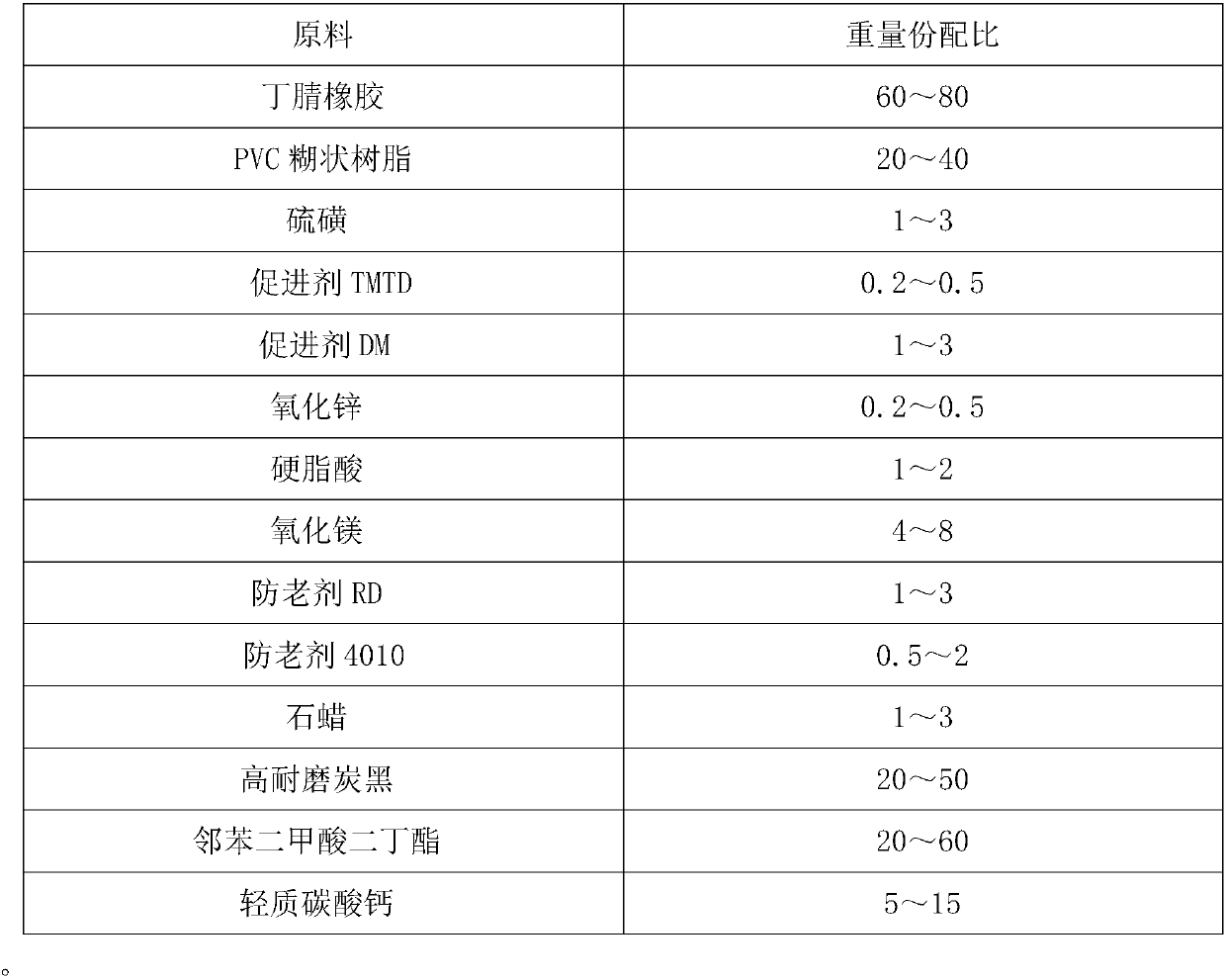

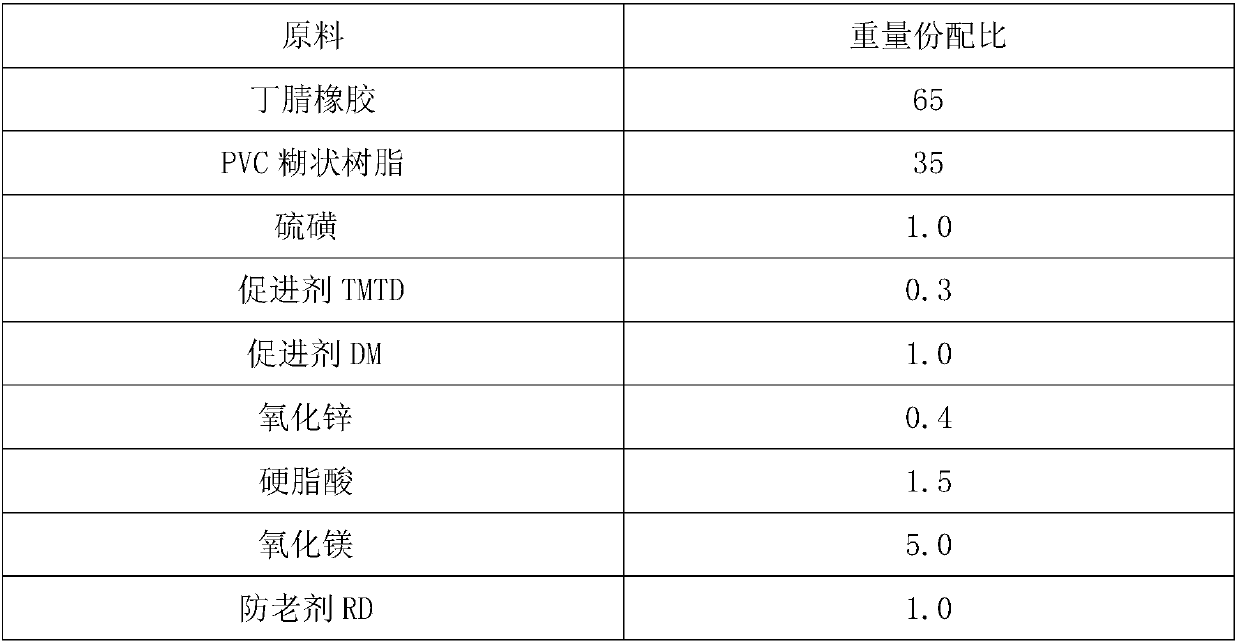

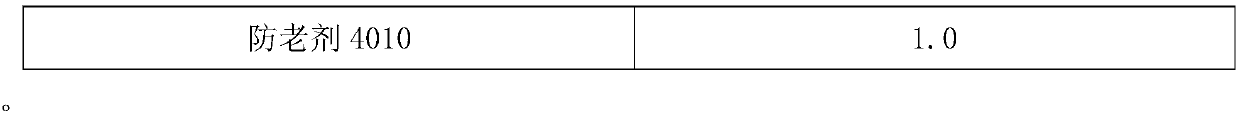

[0015] Examples of rubber materials and their weight ratios:

[0016]

[0017] The rubber material has been tested and its properties are as follows:

[0018]

[0019]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention provides a surface adhesive sizing material for an oil tank sealing tape adhesive tape. The surface adhesive sizing material takes nitrile rubber and PVC paste resin as main materials and high abrasion furnace carbon black, light calcium carbonate and dibutyl phthalaten as auxiliary materials, the materials are matched and mixed in parts by weight, and the rubber compound is manufactured through mixing of an internal mixer. The surface adhesive sizing material has high tensile strength, good abrasion resistance and good oil resistance, and is preferably applicable to the requirements of oil tank sealing devices for sealing tape oil resistance and abrasion resistance. The sizing material is high in aging resistance, high in cold resistance and long in service life.

Description

technical field [0001] The invention relates to an oil tank sealing tape, in particular to an oil tank sealing tape adhesive cloth surface rubber material. Background technique [0002] The oil tank sealing belt is the structural main body of the floating roof oil tank sealing device. It is made of oil-resistant and weather-resistant rubber after vulcanization. It has enough flexibility and can fit well with the tank wall. It is mainly used for floating roof oil storage tanks and chemical product storage tanks. It is installed on the edge plate of the floating roof of the storage tank. The sealing tape makes sliding contact with the tank wall as the floating plate rises and falls, and uses the sealing tape (wrapped with sponge or liquid-filled) itself Seal between the elastic and the tank. To reduce and prevent the volatilization of the medium to achieve the purpose of saving. [0003] Nitrile rubber is produced by emulsion polymerization of butadiene and acrylonitrile. Ni...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C08L9/02C08L27/06C08L91/06C08K13/02C08K3/04C08K3/06C08K3/26C08K5/12C08K5/09

CPCC08K2003/265C08L9/02C08L2201/08C08L2205/03C08L27/06C08L91/06C08K13/02C08K3/04C08K3/06C08K3/26C08K5/12C08K5/09

Inventor 陶刚熊明明周明

Owner 中国化工集团曙光橡胶工业研究设计院有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap