Bronzing glue for rough substrate and production process of bronzing glue

A production process and substrate technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of incompatibility with rough substrates, deep texture, and inability to develop bronzing prints well. , to achieve the effect of suitable for large-scale application, simple operation procedure and improved coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

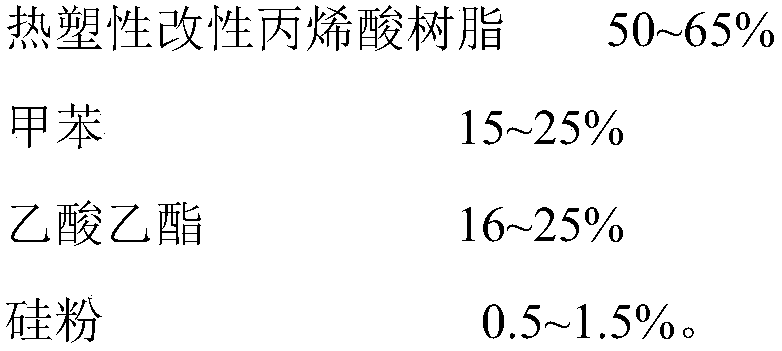

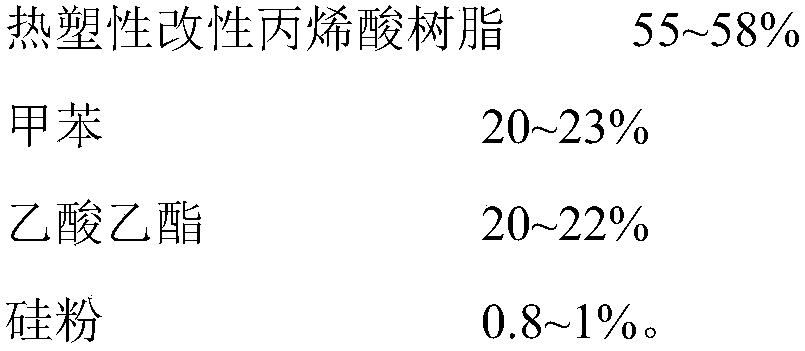

[0023] A kind of bronzing glue for rough base material in the present embodiment is made up of the raw material of following percentage by weight:

[0024] Thermoplastic modified acrylic resin 50%, toluene 25%, ethyl acetate 23.5%, silicon powder 1.5%.

[0025] The production process steps of this bronzing glue are as follows:

[0026] Step 1. Mixing materials for the first time: According to the weight percentage of the raw materials in the above-mentioned embodiment, weigh the modified acrylic resin, toluene, and ethyl acetate respectively, and then add them to the agitator and mix them evenly. The mixing temperature is a constant temperature of 25°C. Mixing time is 25min, obtains the first mixture;

[0027] Step 2, the second mixing: weigh the formula amount of silicon powder according to the weight percentage of the raw materials in the above-mentioned embodiment. When weighing the formula amount of silicon powder, it is necessary to increase the amount of silicon powder....

Embodiment 2

[0029] A kind of bronzing glue for rough base material in the present embodiment is made up of the raw material of following percentage by weight:

[0030] Thermoplastic modified acrylic resin 65%, toluene 18.5%, ethyl acetate 16%, silicon powder 0.5%.

[0031] The production process steps of this bronzing glue are as follows:

[0032] Step 1. Mixing materials for the first time: According to the weight percentage of the raw materials in the above-mentioned embodiment, weigh the modified acrylic resin, toluene, and ethyl acetate respectively, and then add them to the agitator and mix them evenly. The mixing temperature is a constant temperature of 28°C. Mixing time is 28min, obtains the first mixture;

[0033] Step 2, the second mixing: weigh the formula amount of silicon powder according to the weight percentage of the raw materials in the above-mentioned embodiment. When weighing the formula amount of silicon powder, it is necessary to increase the amount of silicon powder....

Embodiment 3

[0035] A kind of bronzing glue for rough base material in the present embodiment is made up of the raw material of following percentage by weight:

[0036] Thermoplastic modified acrylic resin 54%, toluene 20%, ethyl acetate 25%, silicon powder 1%.

[0037] The production process steps of this bronzing glue are as follows:

[0038] Step 1. Mixing materials for the first time: According to the weight percentage of the raw materials in the above-mentioned embodiment, weigh the modified acrylic resin, toluene, and ethyl acetate respectively, and then add them to the agitator and mix them evenly. The mixing temperature is a constant temperature of 30°C. Mixing time is 30min, obtains the first mixture;

[0039] Step 2, the second mixing: weigh the formula amount of silicon powder according to the weight percentage of the raw materials in the above-mentioned embodiment. When weighing the formula amount of silicon powder, it is necessary to increase the amount of silicon powder. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com