Making method of rose vinegar

A rose vinegar and rose flower technology, applied in the preparation of vinegar, etc., can solve the problems of affecting the unique fragrance of roses, not meeting the consumer groups, and uncontrollable changes of roses, etc., achieving good astringent effect, avoiding adverse effects, and transparency of vinegar Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

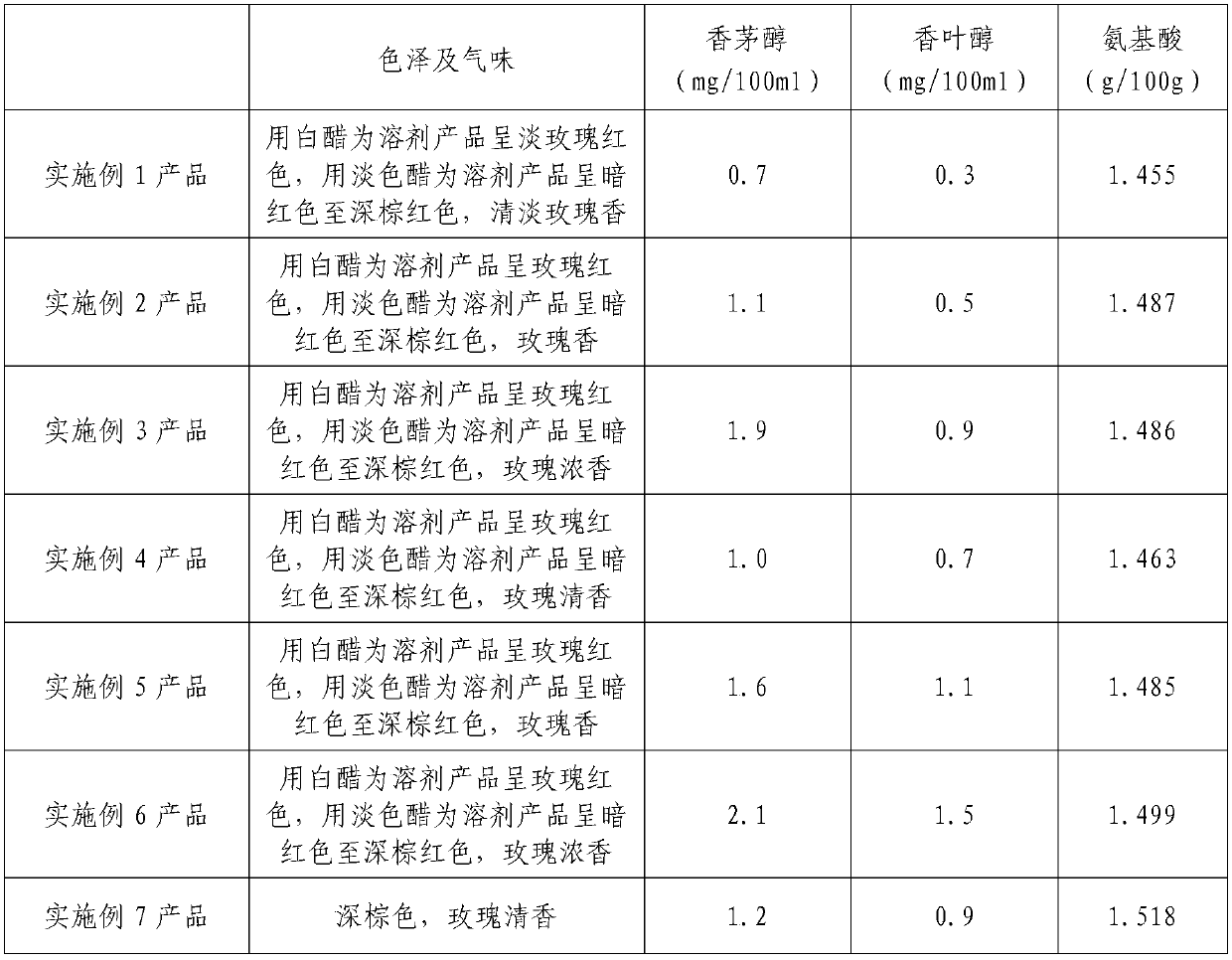

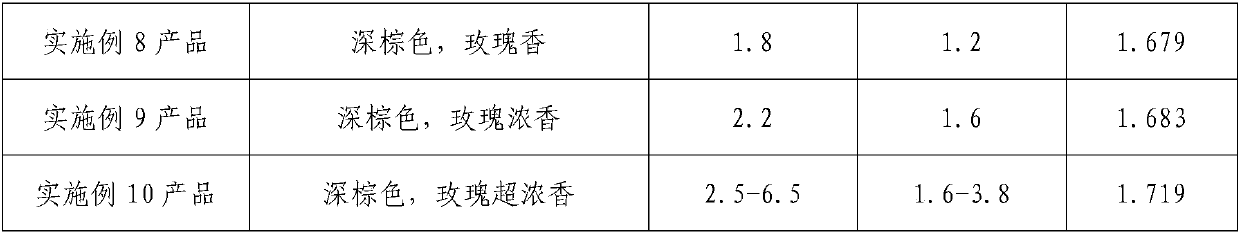

Examples

Embodiment 1

[0037] The preparation method of rose vinegar comprises the following processing steps:

[0038] A. Rose raw material selection

[0039] Select roses whose petals are open and not fully expanded, or roses whose buds are about to open, or whose buds are fully enlarged and about to open, and dry the above raw materials at low temperature;

[0040] B. Micronization treatment

[0041] Micronizing the dried material in step A at low temperature;

[0042] C. Leaching

[0043] Dissolve the micropowder of the material prepared in step B in vinegar, stir and mix well, and then let it stand until the solution is clear and transparent without suspended matter;

[0044] D. Filtration filling.

[0045] The moisture content of the dried rose raw material in the step A is lower than 8%.

[0046] In the step A, the dried rose raw material is preserved by vacuum, nitrogen filling or deoxygenation.

[0047] The method of low-temperature drying in the step A adopts one or a combination of dr...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is:

[0054] In the step C, the vinegar is selected from white vinegar or light-colored vinegar, and the material micropowder prepared in the step B has a mesh size of 50 mesh, and the mass ratio of the material micropowder prepared in the step B: vinegar is 1:20.

[0055] The rest of the content is the same as the embodiment.

Embodiment 3

[0057] The difference between this embodiment and embodiment 1 is:

[0058] In the step C, the vinegar is white vinegar or light-colored vinegar, and the material micropowder prepared in the step B has a mesh size of 35 mesh, and the mass ratio of the material micropowder prepared in the step B: vinegar is 1:500.

[0059] The rest of the content is the same as the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com