Method for removing oxidation film of seven-series aluminum mirror surface after anodizing

An oxide film and post-oxidation technology, which is applied in the field of removing the oxide film after the seven-series aluminum mirror anode, can solve the problems of high scrap rate, high cost, complicated process, etc., and achieve the effect of complete removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for removing the oxide film after the seven-series aluminum mirror anode. Firstly, the workpiece with the oxide film after the seven-series aluminum mirror anode is placed in a degreasing and degreasing agent for treatment, and then washed with 70℃ hot water, and then the removing liquid is prepared and heated At 60℃, place the workpiece with the oxide film after the seven-series aluminum mirror anode in the removal solution and immerse it for 15s. Take out the workpiece and rinse it repeatedly with deionized water and air dry. Then put the workpiece in the removal solution and immerse it for 30s. Wash and dry. And during the immersion process, ultrasonic equipment is used to apply ultrasonic waves to the stripping liquid.

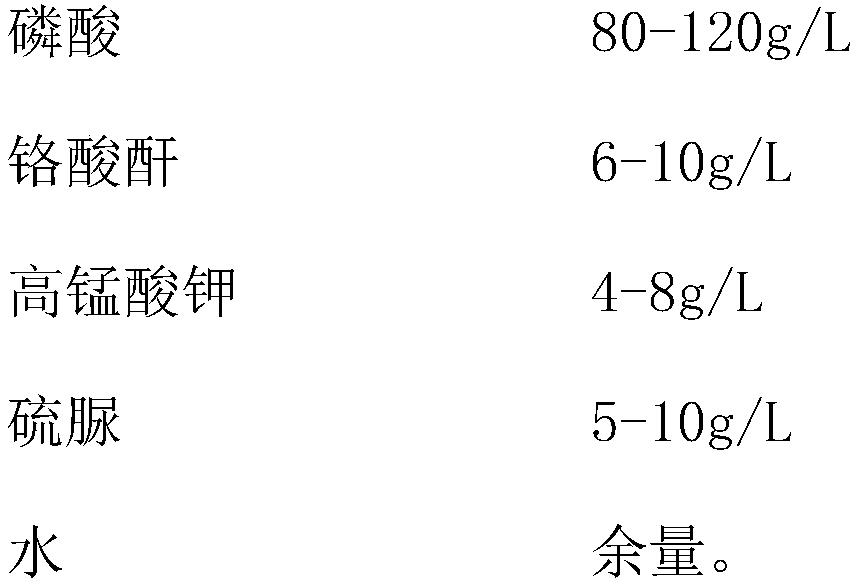

[0021] Among them, the formula of the degrading liquid is: phosphoric acid 80g / L, chromic anhydride 6g / L, potassium permanganate 4g / L, thiourea 5g / L, and the balance is water.

[0022] Among them, the formula of the degreasing agent is: sodium ...

Embodiment 2

[0024] A method for removing the oxide film after the seven-series aluminum mirror anode. Firstly, the workpiece of the oxide film after the seven-series aluminum mirror anode is placed in a degreasing and degreasing agent for treatment, and then washed with 80℃ hot water, and then the removing liquid is prepared and heated At 70℃, place the workpiece with the oxide film after the seven-series aluminum mirror anode in the removal solution and immerse it for 20s. Take out the workpiece and rinse it repeatedly with deionized water and air dry. Then put the workpiece in the removal solution and immerse it for 40s. Wash and dry. And during the immersion process, ultrasonic equipment is used to apply ultrasonic waves to the stripping liquid.

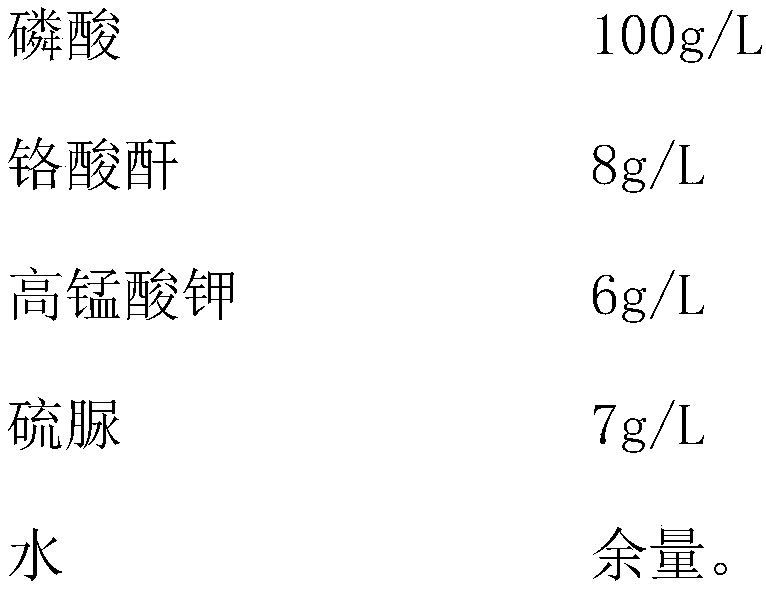

[0025] Among them, the formula of the degrading liquid is: phosphoric acid 100g / L, chromic anhydride 8g / L, potassium permanganate 6g / L, thiourea 8g / L, and the balance is water.

[0026] Among them, the formula of the degreasing agent is: sodium c...

Embodiment 3

[0028] A method for removing the oxide film after the seven-series aluminum mirror anode. Firstly, the workpiece with the oxide film after the seven-series aluminum mirror anode is placed in a degreasing and degreasing agent for treatment, and then cleaned with 85°C hot water, and then the removing solution is prepared and heated At 80℃, place the workpiece with the oxide film after the seven-series aluminum mirror anode in the removal solution and immerse it for 25s. Take out the workpiece and rinse it repeatedly with deionized water and air dry. Then put the workpiece in the removal solution and immerse it for 50s. Wash and dry. And during the immersion process, ultrasonic equipment is used to apply ultrasonic waves to the stripping liquid.

[0029] Among them, the formula of the degrading solution is: phosphoric acid 120g / L, chromic anhydride 10g / L, potassium permanganate 4g / L, thiourea 10g / L, and the balance is water.

[0030] Among them, the formula of the degreasing agent is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com