Trimming woven label and preparation method thereof

A technology of trimming and weaving labels, applied in the field of woven labels, can solve the problems of difficulty in further obtaining high-quality trimming and woven labels, inconvenient mechanical positioning of garment factories, poor dimensional stability, etc. Shrinkage characteristics, dimensional stability, and the effect of preventing fraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

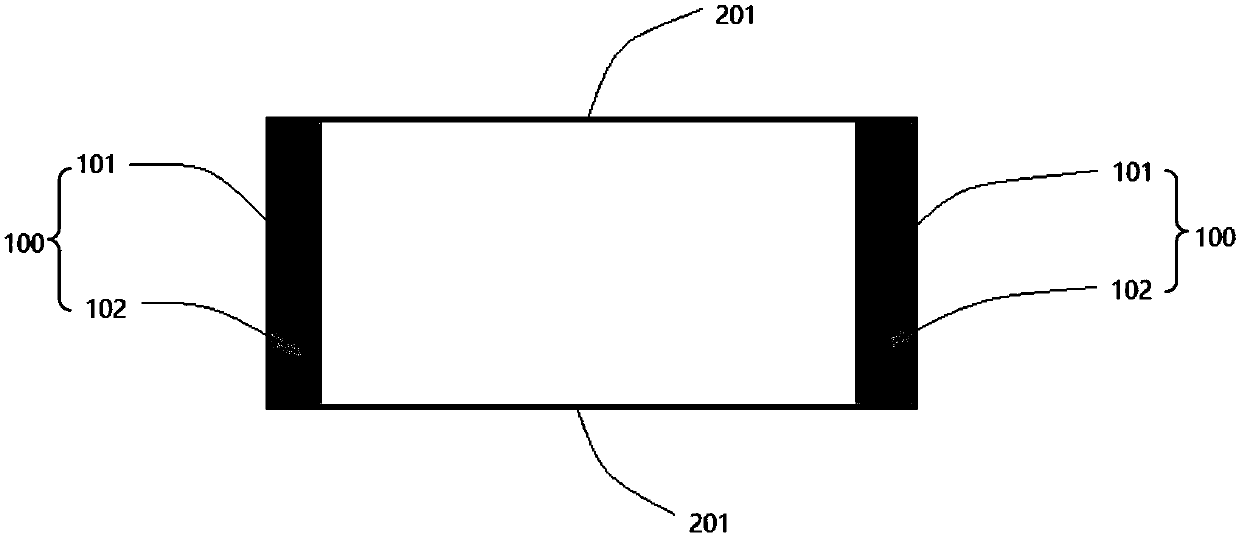

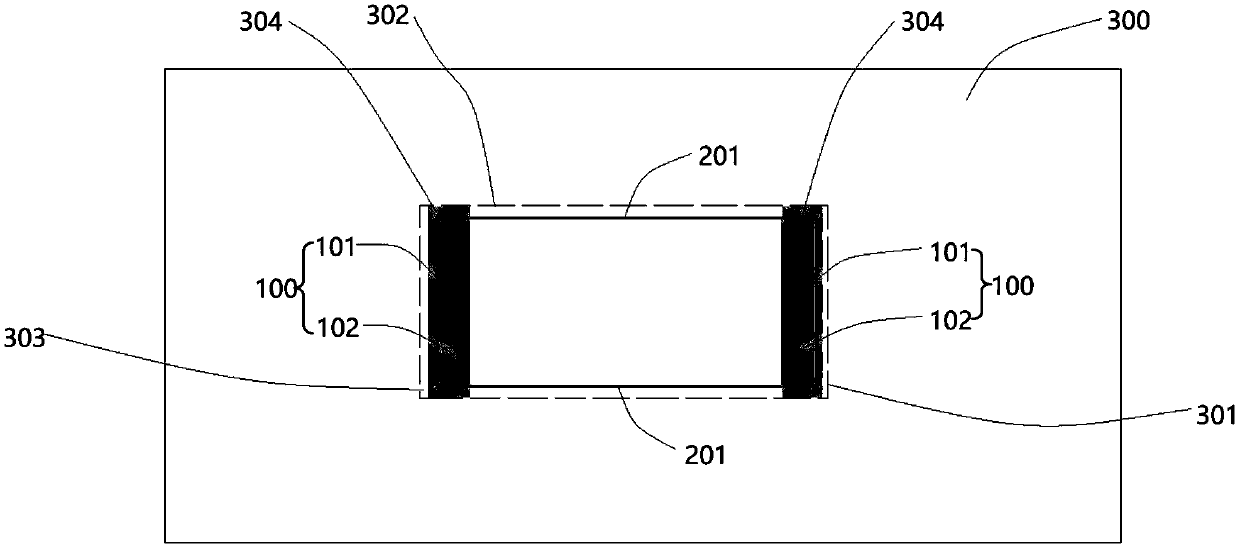

[0049] In this embodiment, a method for preparing a trimmed woven label, the trimmed woven label is as follows: figure 1 As shown, the shape is a rectangle, including two first side regions 100 oppositely arranged, the first side region 100 includes a first woven label side 101 and an overlock region 102 arranged along the first woven label side 101, The first woven label side 101 is the side that is exposed and in contact with the user's skin; the trimmed woven label also includes two opposite second woven label sides 201, and the second woven label side 201 will be processed during the preparation process. Folded inward, out of contact with the user's skin.

[0050] The preparation method of above-mentioned trimming woven label comprises the steps:

[0051] (1) Setting the direction of the woven label pattern: Arrange the warp direction of the preset woven label pattern according to the warp direction of the woven label gray cloth.

[0052] (2) Perform low-temperature bulk...

Embodiment 2

[0063] A kind of preparation method of edge-trimming woven label of this embodiment, its structure is similar to embodiment 1, and preparation method comprises the following steps:

[0064] (1) The graphic direction setting of the woven label: arrange the warp direction of the woven label pattern according to the weaving weft direction.

[0065] (2) Perform low-temperature bulking agent and permanent antistatic finishing on the weft yarn: add water, silicone softener, polyester fluffy softener SR 2.0~5.0g / L (from Dongguan Xianqiao Auxiliary Industry Co., Ltd. Company), antistatic finishing agent TG-01A 1 ~ 3g / L (from Huntsman Chemical), run at 45°C for 25min, drain, dehydrate, and dry, and prepare for use.

[0066] (3) Preparation of overlock weft yarn for preventing loose edges: use 10D~50D high-strength, low-elasticity polyester yarn (shrinkage rate less than 1.0%) as the inner core, and use 1~3 pieces of 10~50D 80~160℃ low-temperature thermal fuse For the periphery, use co...

Embodiment 3

[0078] A kind of preparation method of edge-trimming woven label of this embodiment, its structure is similar to embodiment 1, and preparation method comprises the following steps:

[0079] (1) Setting the direction of the woven label pattern: Arrange the warp direction of the preset woven label pattern according to the warp direction of the woven label gray cloth.

[0080] (2) Apply low-temperature bulking agent to the weft yarn: add water, silicone softener, polyester fluffy softener SR 2.0~5.0g / L (from Dongguan Xianqiao Auxiliary Industrial Co., Ltd.) into the package dyeing machine, and run at 45°C After 25 minutes, drain, dehydrate, and dry, and prepare it for use.

[0081] (3) Preparation of overlock weft yarn for preventing loose edges: use 10D~50D high-strength, low-elasticity polyester yarn (shrinkage rate less than 1.0%) as the inner core, and use 1~3 pieces of 10~50D 80~160℃ low-temperature thermal fuse For the periphery, use core-spun parallel twisting to produce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com