Dyed cloth dehydration full-automatic system

A fully automatic and cloth dyeing technology, applied in the field of fully automatic dyeing and dehydration systems, can solve problems such as affecting production efficiency and economic benefits, labor and time consumption, and achieve the effect of improving production efficiency and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

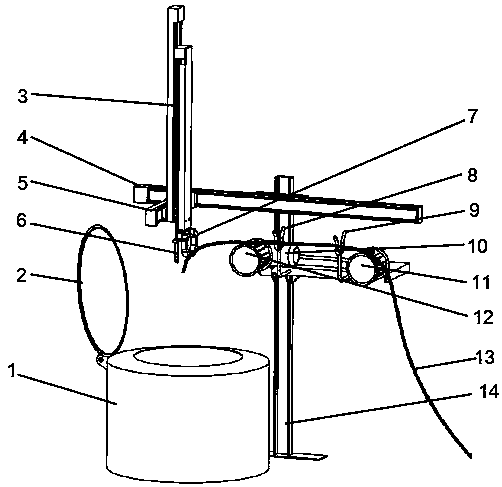

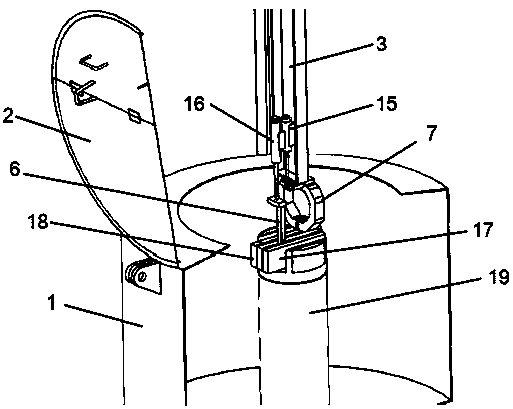

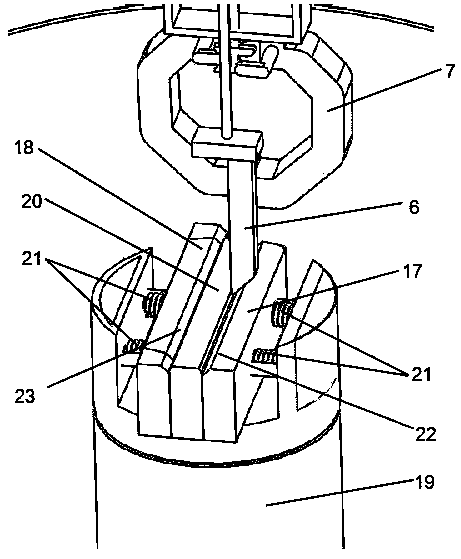

[0031] In the following, in conjunction with the drawings and embodiments, a non-limiting description of the technical solutions described in the present application will be given.

[0032] Such as figure 1 As shown, the fully automated system for dyeing fabric dehydration described in the present application includes a dehydrator 1. A cylinder head 2 is provided on the cylinder of the dehydrator 1, and the opening and closing of the cylinder head 2 is operated by the cylinder automatic device; the column of the manipulator device The axis 3, the horizontal axis 4 and the vertical axis 5 are assembled on the manipulator pillar 14 to provide synchronous movement of the XYZ axis. The rear cloth guide fork 8, the front cloth guide fork 9, the cloth lifting roller drive 10, the front cloth roller 11, and the rear cloth lifting roller 12 constitute a set of dyeing cloth transportation equipment, which is installed on the manipulator support 14. The function of the dyed cloth transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com