A highly automated and information-intelligent airbag cloth inkjet trimming machine and its working method

A working method, the technology of airbag cloth, applied in the direction of overall factory control, electrical program control, overall factory control, etc., can solve the problems of low efficiency of centering device, error of trimming width, mandrel weight, etc., and achieve the improvement of automation , improve operating efficiency, and reduce investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

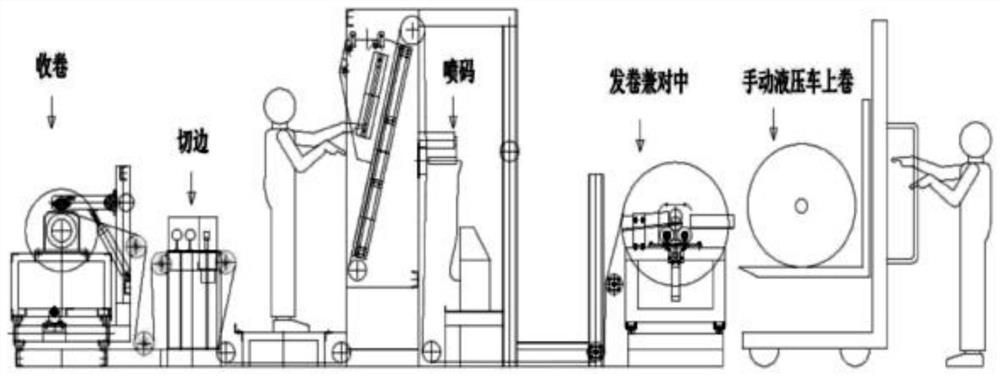

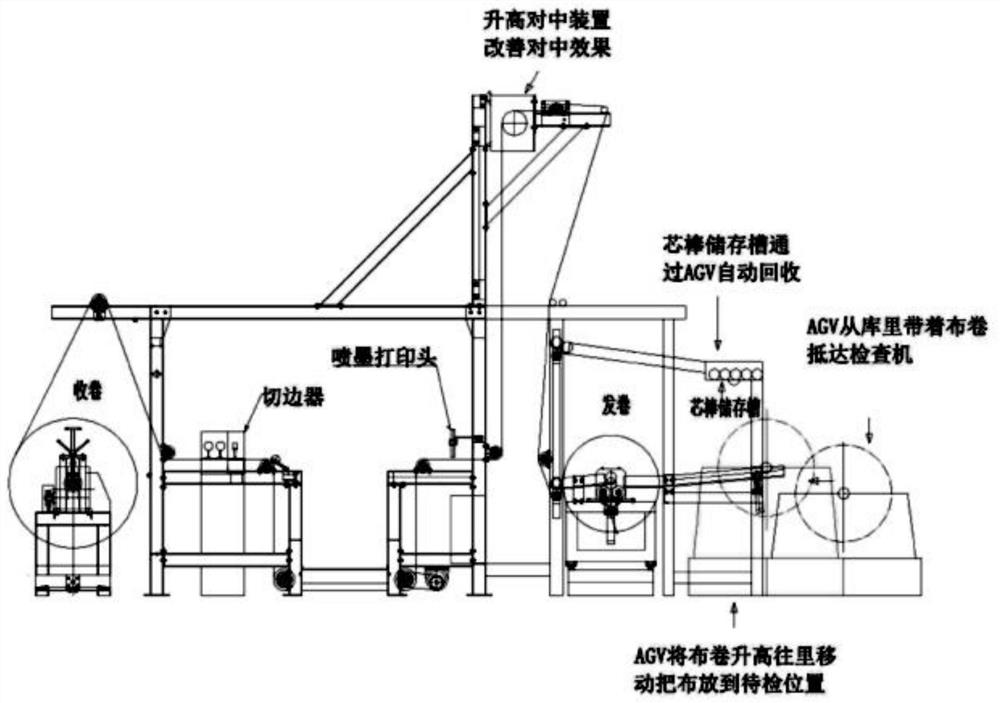

[0032] The invention solves the problems that the weight of the airbag cloth is relatively large, the cloth roll is relatively heavy about 1 ton, and the handling and loading and unloading are relatively laborious.

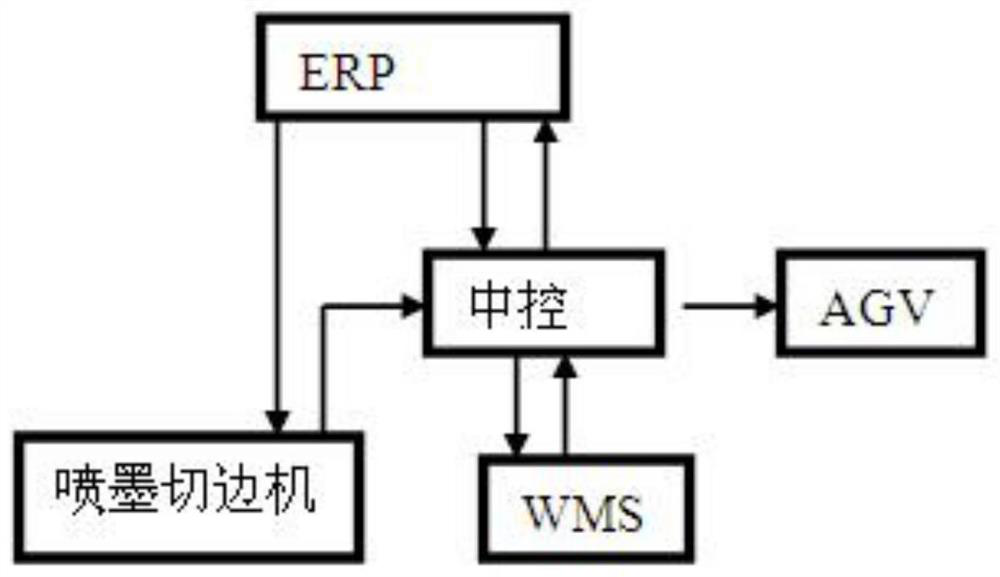

[0033] Since AGV was invented in the 1970s, it has been used in many industries, such as Amazon, paper and so on. However, this technology is rarely used in the printing and dyeing industry. The main reason is that the logistics lines of the printing and dyeing factory are complex, the specifications of the cloth rolls are various, and the weight and weight are different. Since the beginning of this century, with the advancement of science and technology, the improvement of computer capabilities, and the improvement of navigation technology, it is possible to apply AGV in the printing and dyeing industry, and the logistics automation problem in the production process of the printing and dyeing industry may be solved. The characteristics of the airbag cloth roll ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com