Bearing vibration measurement mechanism and bearing detection device

A technology for measuring vibration and bearings, which is applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc. It can solve the problems of affecting the measurement effect, uneven force between the inner ring and the outer ring, and automatic detection, etc., so as to improve the effect , even force, and improve the efficiency of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

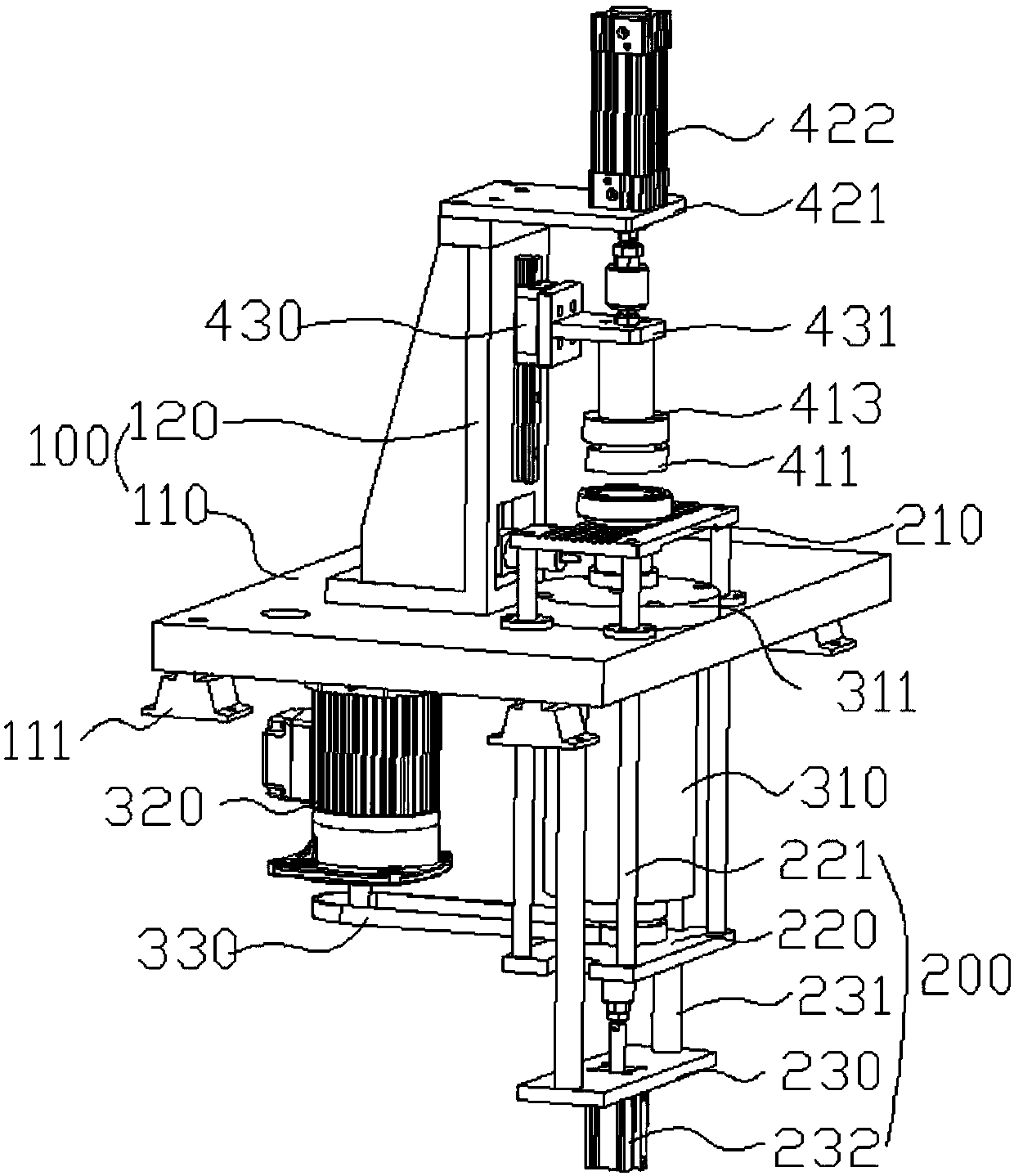

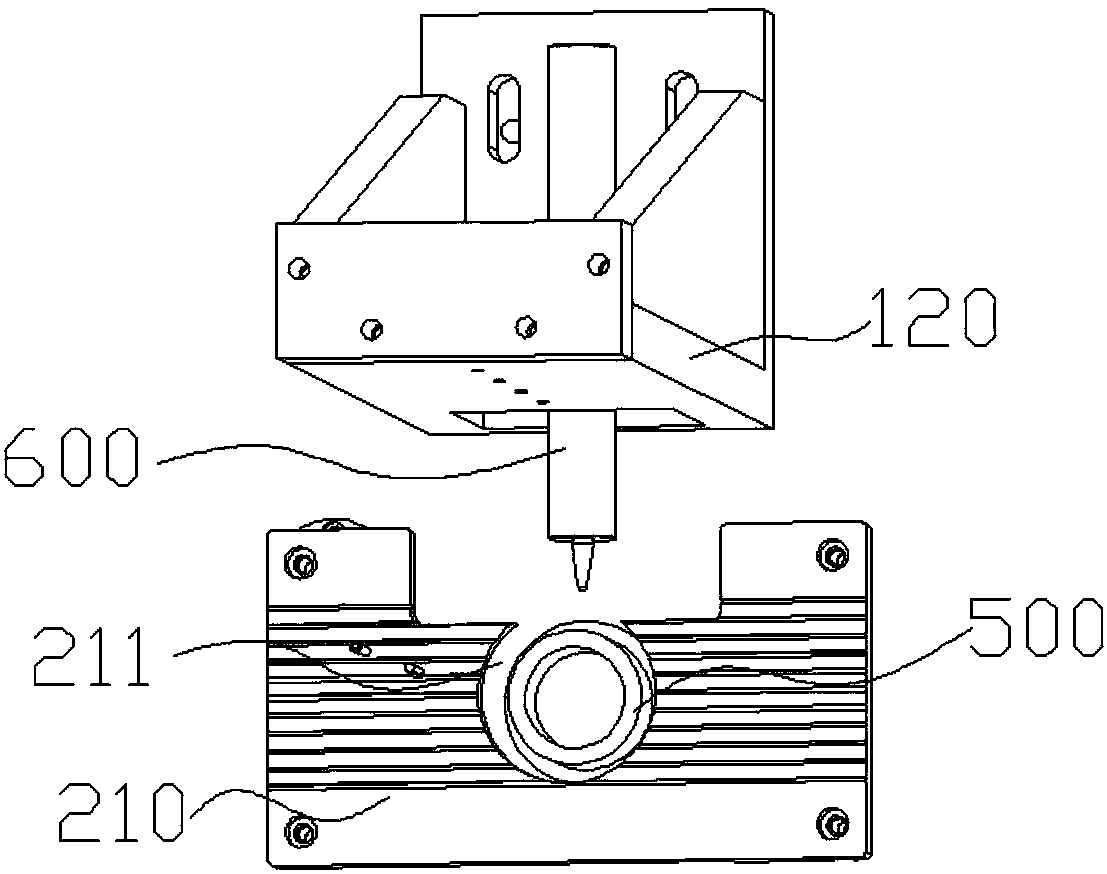

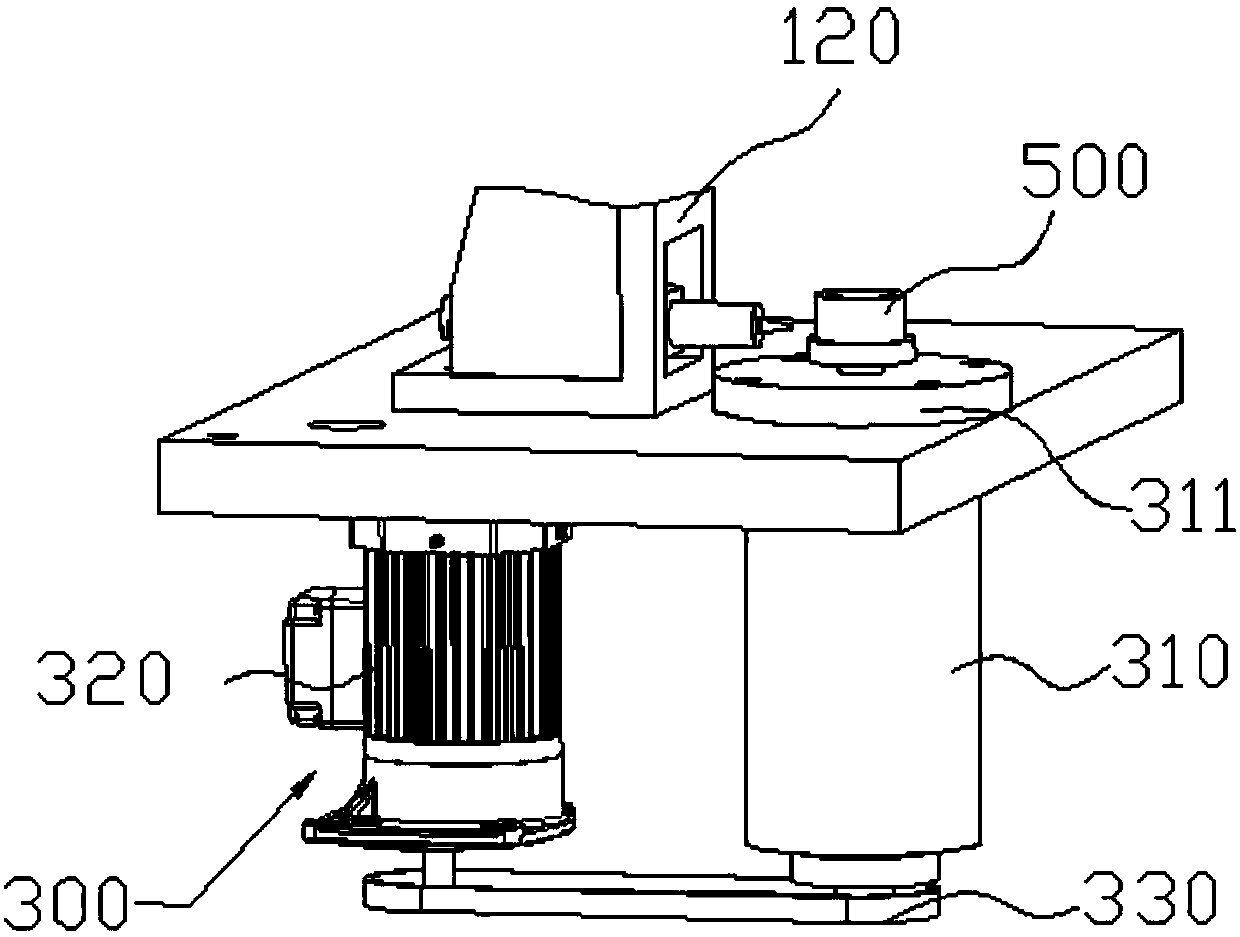

[0042] Such as figure 1 and figure 2As shown, the bearing vibration measuring mechanism provided in this embodiment includes: a support assembly 100, a backing plate assembly for bearing the bearing, a vibration measuring mandrel 500 for fixing the inner ring of the bearing, and a vibration measuring mandrel 500 for driving the bearing. The rotating rotating assembly 300, the circumferential loading assembly 400 for applying axial pressure to the outer ring of the bearing, and the vibration measuring sensor 600 for measuring the vibration of the outer ring when the inner ring of the bearing rotates; the backing plate assembly includes the backing plate 210 and The second drive assembly 200 that drives the backing plate 210 to move in the vertical direction; the backing plate 210 is arranged directly above the output end of the rotating assembly 300, and the backing plate 210 is provided with a through hole 211 that can pass through the vibration measuring mandrel 500; The lo...

Embodiment 2

[0055] The bearing detection equipment provided in this embodiment includes: a manipulator and the bearing vibration measuring mechanism provided in Embodiment 1; the manipulator can place the bearing on the backing plate 210 of the bearing vibration measuring mechanism.

[0056] In the bearing testing equipment provided in this embodiment, the bearing is placed on the backing plate 210 by the manipulator to detect the vibration value. After the test, the bearing is taken away by the manipulator to complete the automatic test and improve the efficiency of the test. Wherein, the structure and beneficial effects of the bearing vibration measuring mechanism have been described in detail above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com