Anticorrosion structure design for micro-range silicon piezoresistive sensor

A structural design, silicon piezoresistive technology, applied in the direction of measuring fluid pressure, instruments, measuring force, etc., can solve problems affecting sensor accuracy, erosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

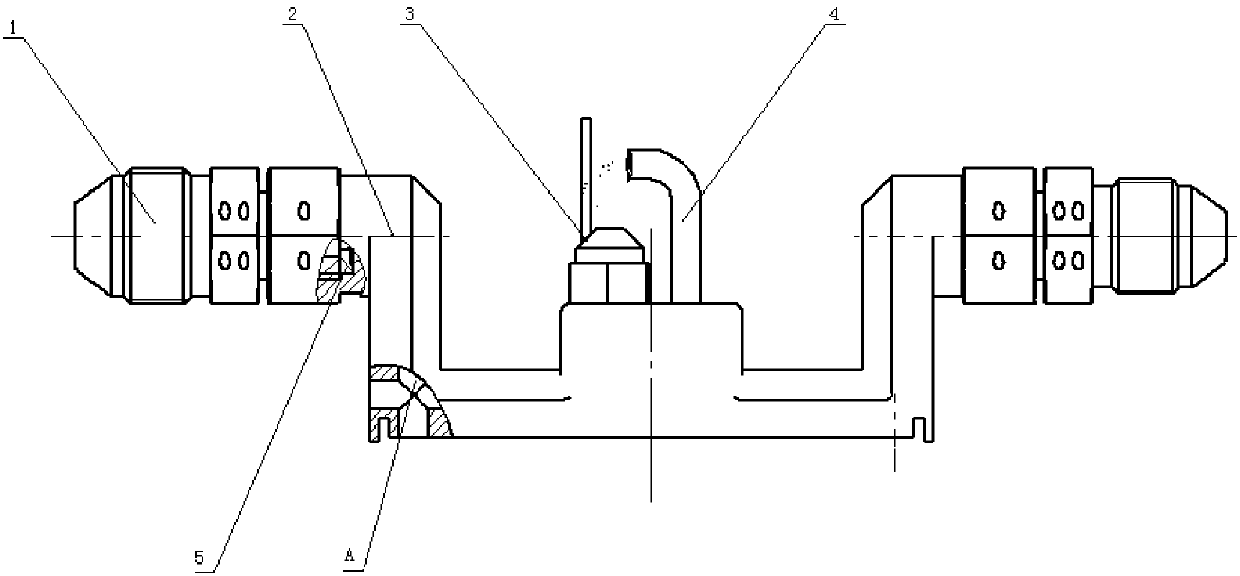

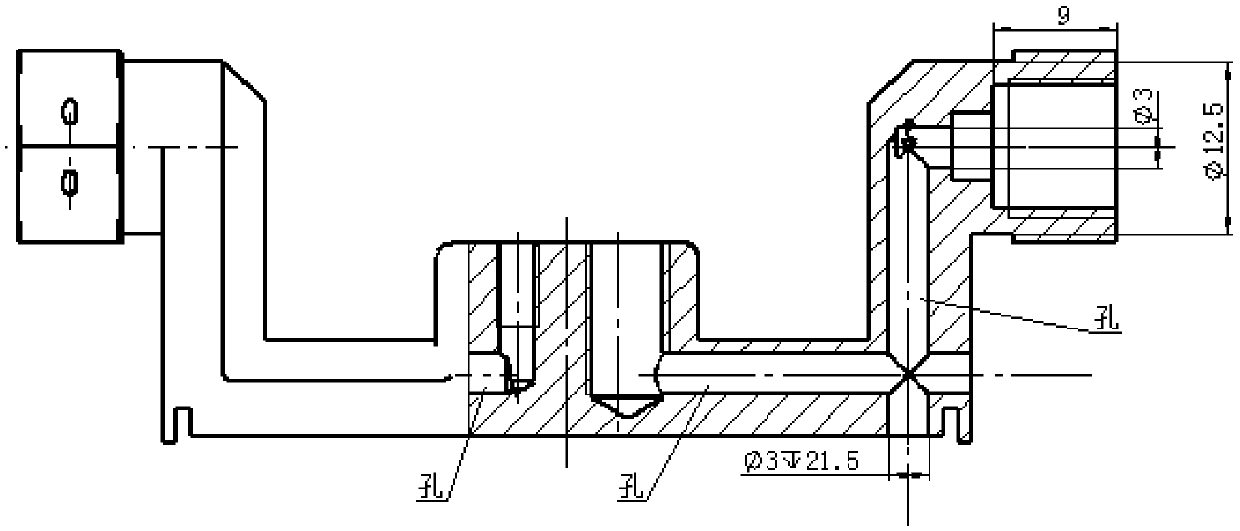

[0019] See attached Figure 1-7 As shown, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

[0020] The anti-corrosion structure of the micro-range silicon piezoresistive sensor is characterized in that:

[0021] The structure mainly includes a pressure nozzle 1 , an adapter 2 , a pressure-sensitive core 3 , a connecting pipe 4 , and a waterproof and breathable device 5 .

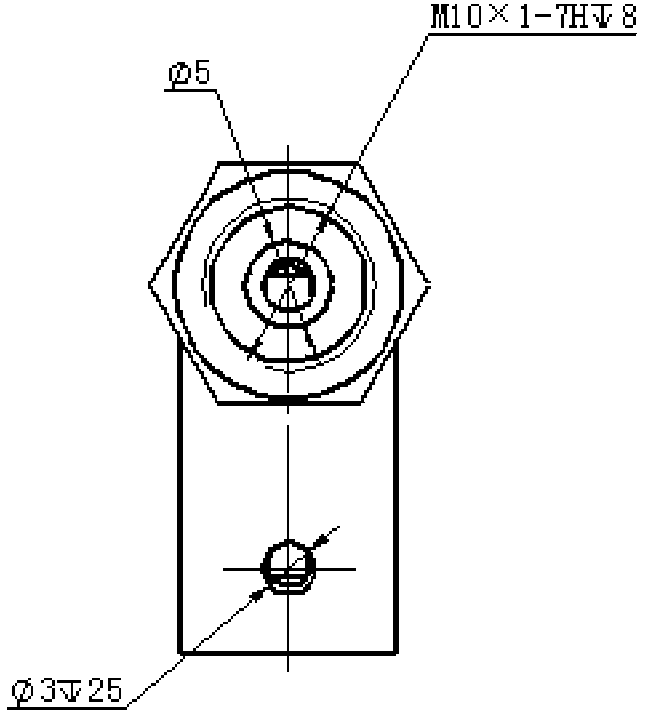

[0022] The pressure nozzle 1 is connected to the adapter 2 through an M10 thread, and the waterproof and ventilating device is installed between the pressure nozzle 1 and the adapter 2, and the pressure nozzle 1 fixes the waterproof and ventilating device 5 by extrusion.

[0023] The pressure-sensing core 3 connects the positive pressure-sensing end to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com