Turbine blade with water erosion-proof coating and preparation method thereof

A technology for steam turbine blades and steam turbines, which is applied to coatings, mechanical equipment, and blade support components, and can solve problems such as poor bonding between coatings and substrates, easy corrosion of brazed seams, large thermal stress and deformation, etc., to achieve Good water erosion resistance, good damage resistance and peeling performance, and the effect of resisting water erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

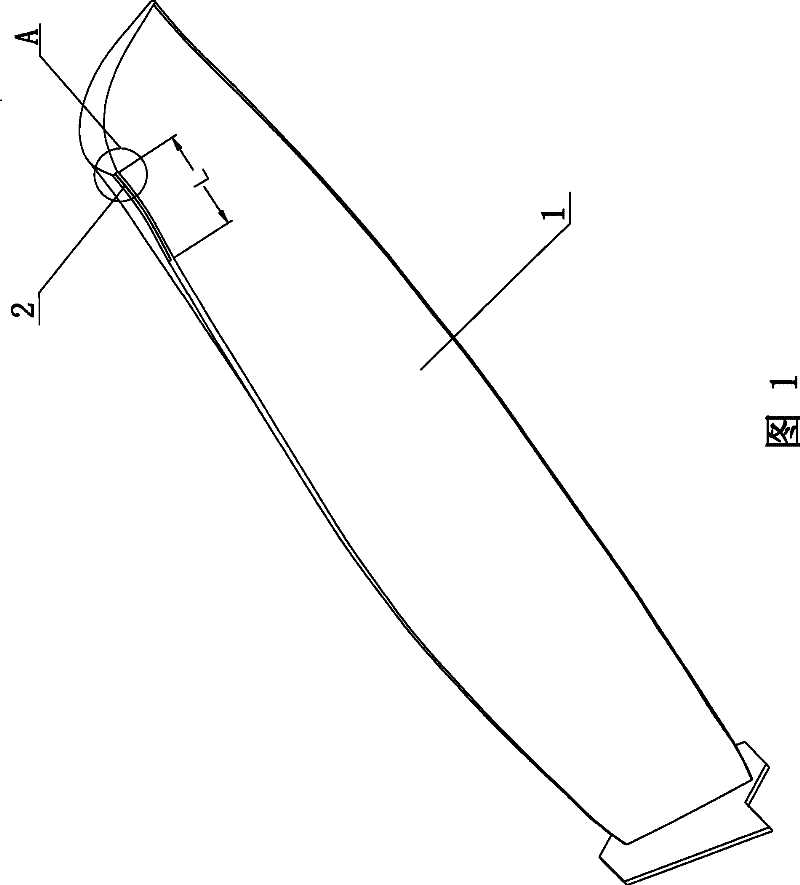

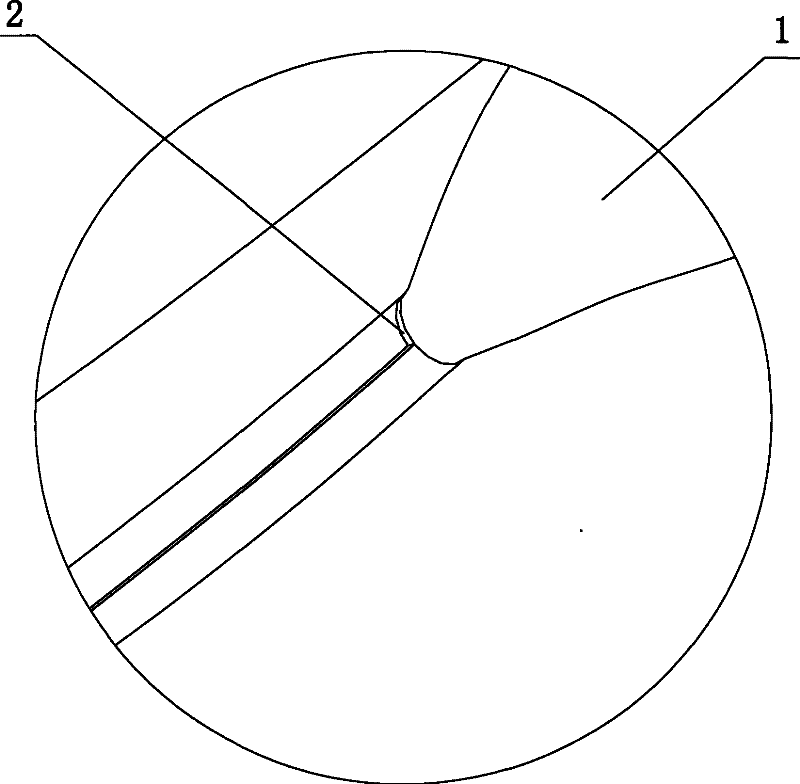

[0014] Such as figure 1 and figure 2 The shown steam turbine blade with an anti-corrosion coating has a length of 620 mm, and the back arc of the top of the steam inlet side of the steam turbine blade substrate 1 is covered with a Cr-Ni stainless steel coating 2 deposited by a high-energy micro-arc spark deposition process. The stainless steel coating 2 has a thickness of 0.4 mm and a length L=11 cm.

[0015] The above-mentioned steam turbine blade with an anti-corrosion coating is prepared through the following steps:

[0016] (1) Grinding the back arc at the top of the steam inlet side of the last stage blade substrate (2Cr13) of the steam turbine, then cleaning and drying with acetone;

[0017] (2) Use 316L alloy with a diameter of 2.5mm as the electrode material, clamp the electrode on the welding torch, control the length of the electrode protruding from the nozzle at 20-40mm, and use high-energy micro-arc deposition technology to deposit the electrode material on the ...

Embodiment 2

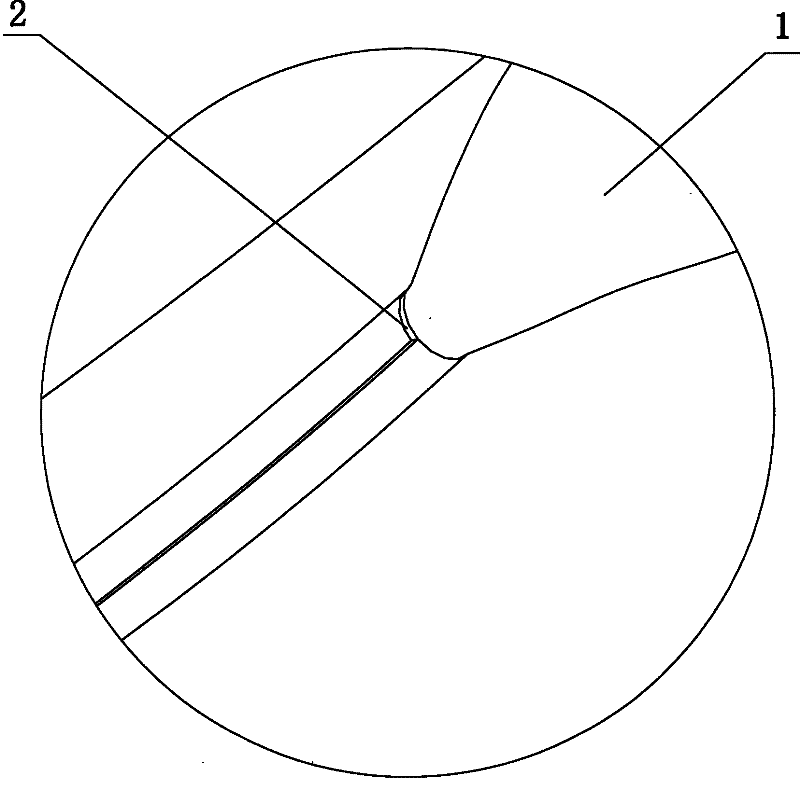

[0021] A steam turbine blade with an anti-corrosion coating of the present invention has a length of 620mm, and the back arc of the top of the steam inlet edge of the steam turbine blade substrate is covered with a Cr-Ni stainless steel coating deposited by a high-energy micro-arc spark deposition process. The stainless steel coating has a thickness of 0.8 mm and a length L=11 cm.

[0022] The above-mentioned steam turbine blade with an anti-corrosion coating is prepared through the following steps:

[0023] (1) Grinding the back arc at the top of the steam inlet side of the last stage blade substrate (2Cr13) of the steam turbine, then cleaning and drying with acetone;

[0024] (2) Use 0Cr19Ni10NbN alloy with a diameter of 2.5mm as the electrode material, clamp the electrode on the welding torch, control the length of the electrode protruding from the nozzle at 20-40mm, and use high-energy micro-arc deposition technology to deposit the electrode material on the polished part; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com