Heating-pressurizing testing device for simulating environmental state in shale air layer and simulating method

A technology of heating and pressurizing and testing equipment, which is applied in the direction of soil material testing, material inspection products, etc., can solve the problems of large floor area, high use and maintenance costs, and large equipment investment, and achieve low cost, stable pressure, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

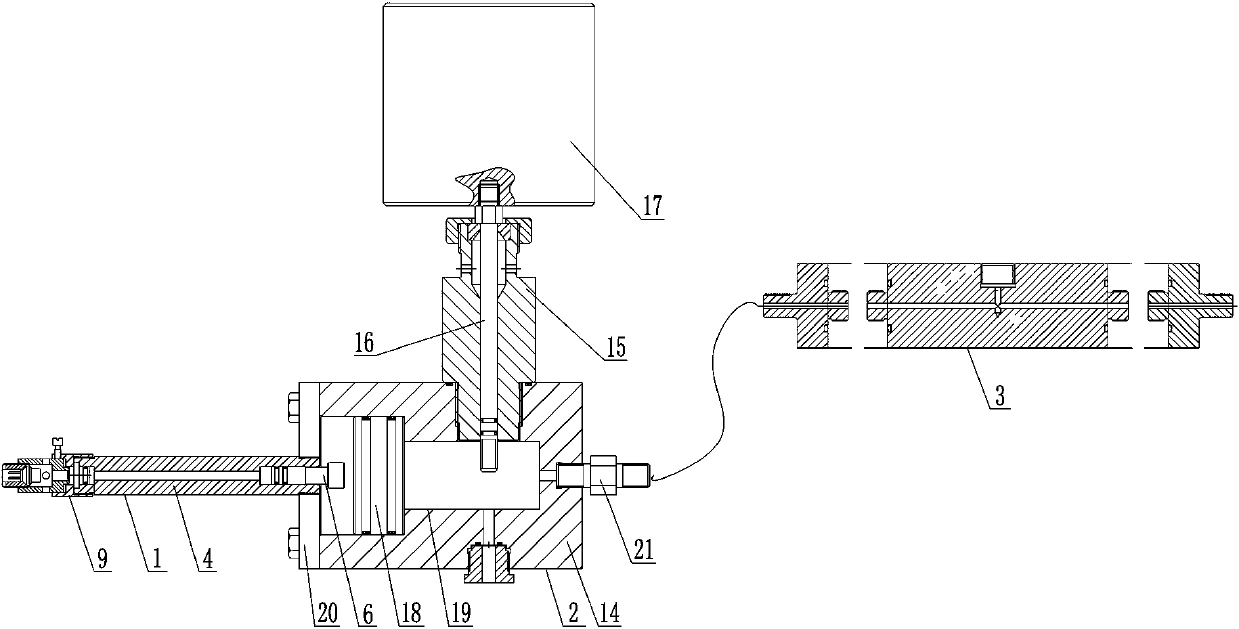

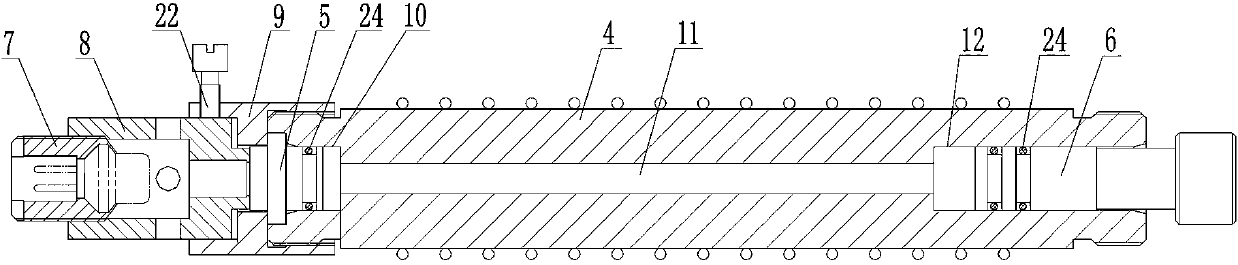

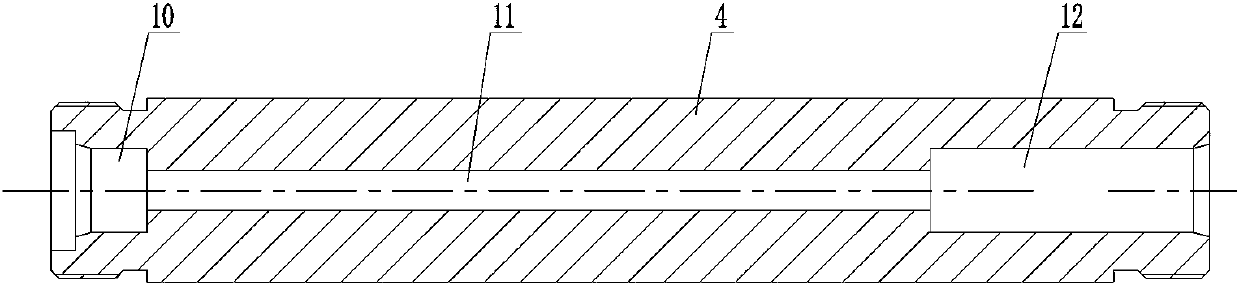

[0023] Such as Figure 1~6 As shown, a heating and pressurizing test device for simulating the environmental state in a shale gas layer includes a charge chamber and an initiation device 1, a pressurization device 2 and a manual pressure test pump 3, and the charge chamber and the detonation device 1 It includes a charge tube 4, a blast transfer seat 5, a charge piston rod 6, a tube seat 7, a detonator seat 8 and an end cover 9, and the charge tube 4 is provided with a blast transfer seat mounting hole 10, a waist Shaped hole 11 and guide hole 12, waist-shaped hole 11 is used for simulating gap transmission, by changing the size of waist-shaped hole 11 in the middle of charge tube 4, gaps of various sizes can be simulated. In the guide hole 12, a pressing piston rod 6 is slidably installed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com