High-protein low-viscosity low-fat milk and preparation method thereof

A low-fat milk and low-viscosity technology, applied in milk preparations, dairy products, applications, etc., can solve the problems of low protein content and thick taste, and achieve the effect of refreshing taste and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing high-protein, low-viscosity, low-fat milk, which comprises the following raw materials: 80%-90% skimmed milk, 5%-7% concentrated casein, 2%-3% concentrated milk protein 0.5 %-1% crystalline fructose, 0.5%-1% medium chain fatty acid, 0.04%-0.06% stabilizer, 0.04%-0.06% emulsifier, 0.02%-0.03% carrageenan, 0.05%-0.08% concentrated fruit juice of Luo Han Guo and water supplemented to 100%; the percentages mentioned are the percentages of the mass of each raw material in the total mass of raw materials;

[0036] Described preparation method, it comprises the steps:

[0037] (1) Skimmed milk is mixed with water, concentrated casein, and concentrated milk protein to obtain feed liquid A;

[0038] (2) Mix feed liquid A with crystalline fructose, medium-chain fatty acid, stabilizer, emulsifier, carrageenan, and Luo Han Guo concentrated fruit juice to obtain feed liquid B;

[0039] (3) Homogenize the material liquid B for the first time, heat treatment, ...

Embodiment 1

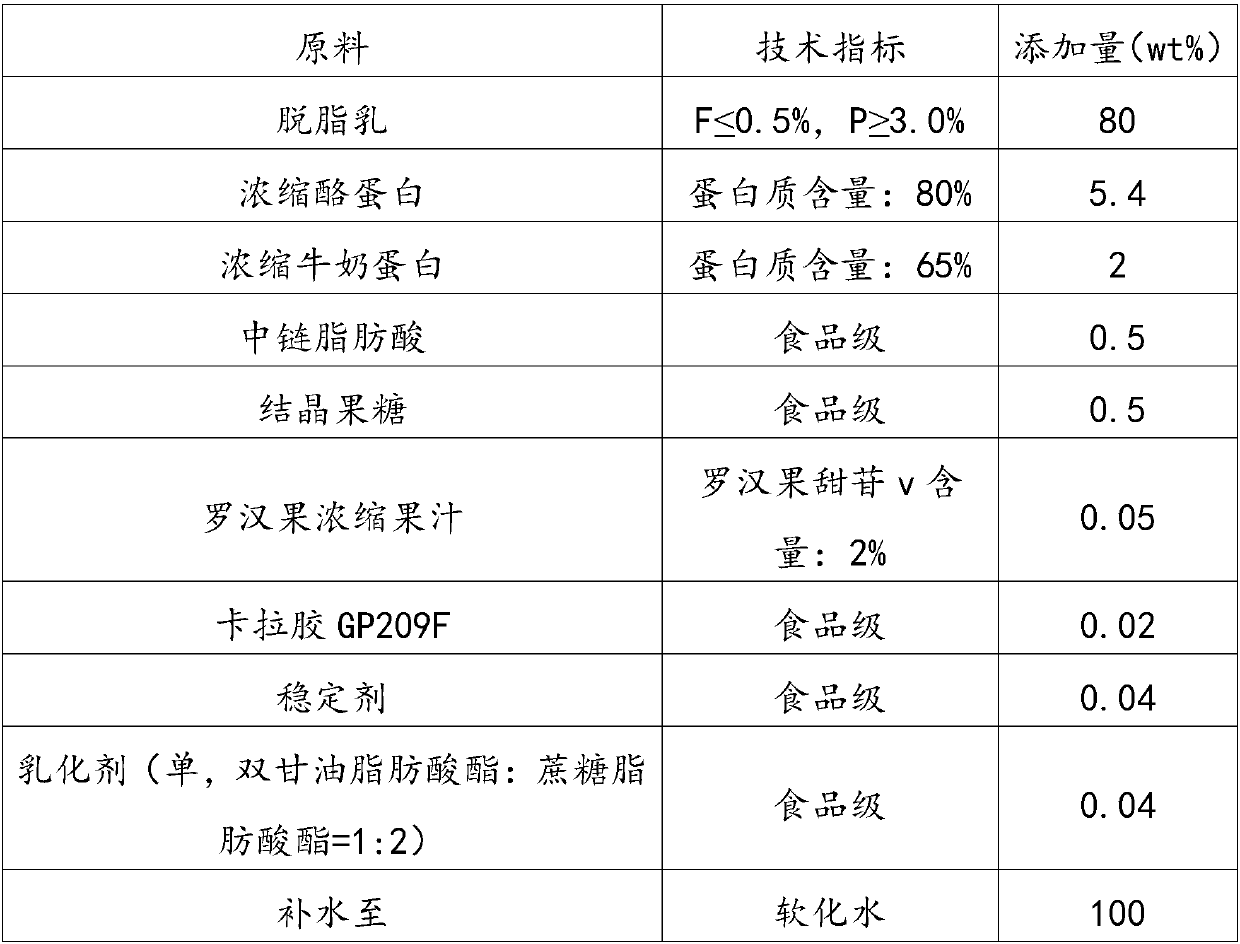

[0061] 1. Raw material formula (see Table 1):

[0062] The raw material formula of table 1 embodiment 1

[0063]

[0064] 2. Preparation method:

[0065] (1) Mix skim milk with water, concentrated casein, and concentrated milk protein (50°C, 50 minutes) to obtain feed liquid A;

[0066] (2) Mix feed liquid A with crystalline fructose, medium-chain fatty acid, stabilizer, emulsifier, carrageenan, and Luo Han Guo concentrated fruit juice (65°C, 15 min) to obtain feed liquid B;

[0067] (3) Material liquid B is homogenized for the first time (primary pressure 15MPa, secondary pressure 5MPa, homogenization temperature 60°C), heat treatment (85°C, 1min), ultra-high temperature sterilization (140°C, 3s), and second Sub-homogeneous (55°C, 18MPa), cooled (20°C), and filled to obtain the high-protein, low-viscosity, low-fat milk.

[0068] The protein and fat content of the product made by this formula are: 8.02%, 0.5%.

Embodiment 2

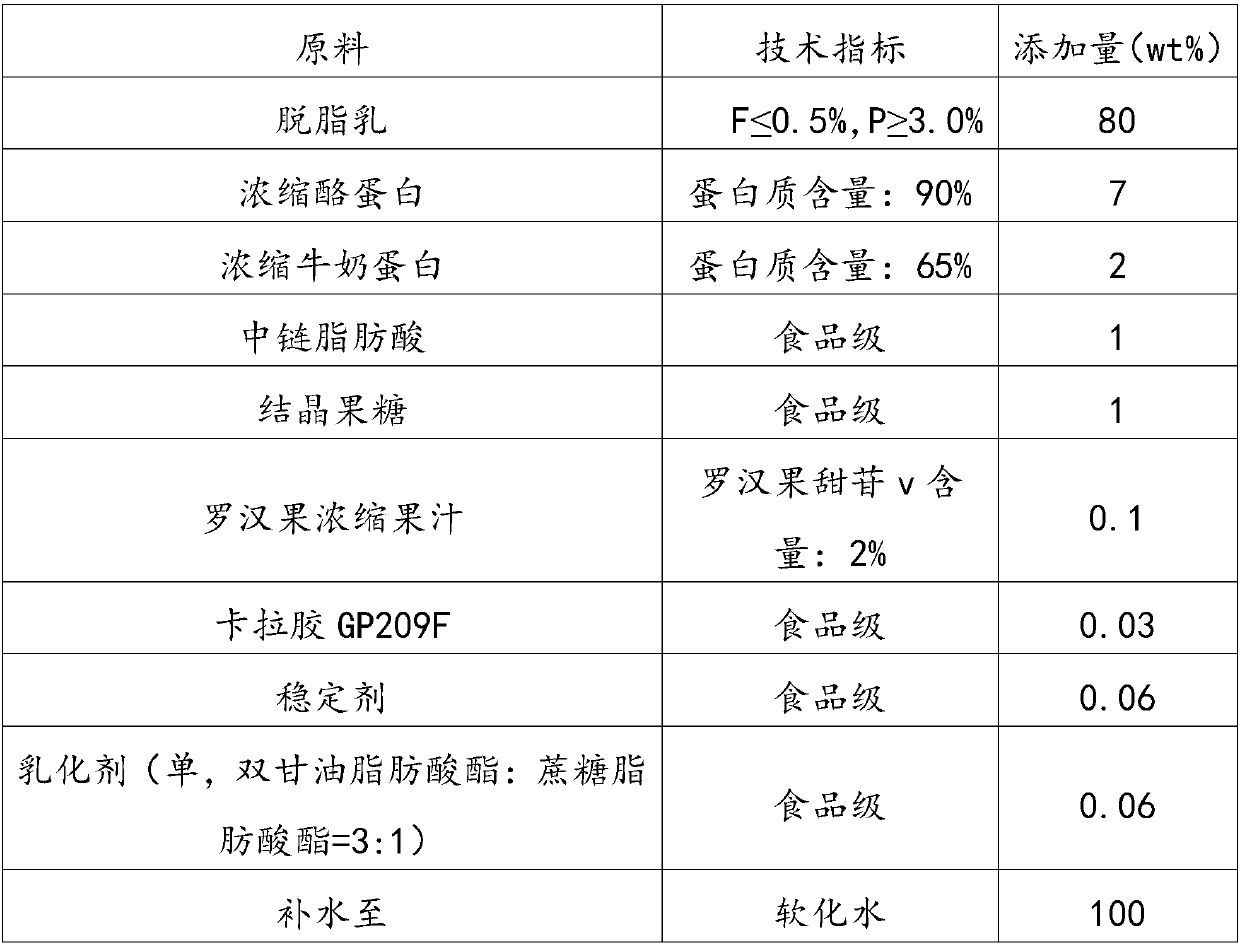

[0070] 1. Raw material formula (see Table 2):

[0071] The raw material formula of table 2 embodiment 2

[0072]

[0073] 2. Preparation method:

[0074] (1) Mix skim milk with water, concentrated casein, and concentrated milk protein (55°C, 60 minutes) to obtain feed liquid A;

[0075] (2) Mix feed liquid A with crystalline fructose, medium-chain fatty acid, stabilizer, emulsifier, carrageenan, and Luo Han Guo concentrated fruit juice (70°C, 20 min) to obtain feed liquid B;

[0076] (3) Material liquid B is homogenized for the first time (primary pressure 20MPa, secondary pressure 10MPa, homogenization temperature 70°C), heat treatment (90°C, 2min), ultra-high temperature sterilization (145°C, 5s), and second Subhomogenize (60°C, 22MPa), cool (20°C), and fill to obtain the high-protein, low-viscosity, low-fat milk.

[0077] The protein and fat content of the product made by this formula are: 10%, 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com