Stepping type precise feed bone drilling device and application thereof

A step-by-step and feeding technology, applied in the field of medical equipment, can solve the problems of drilling too deep, secondary injury, and other tissue damage, and achieve the effect of remarkable effect, simple operation and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

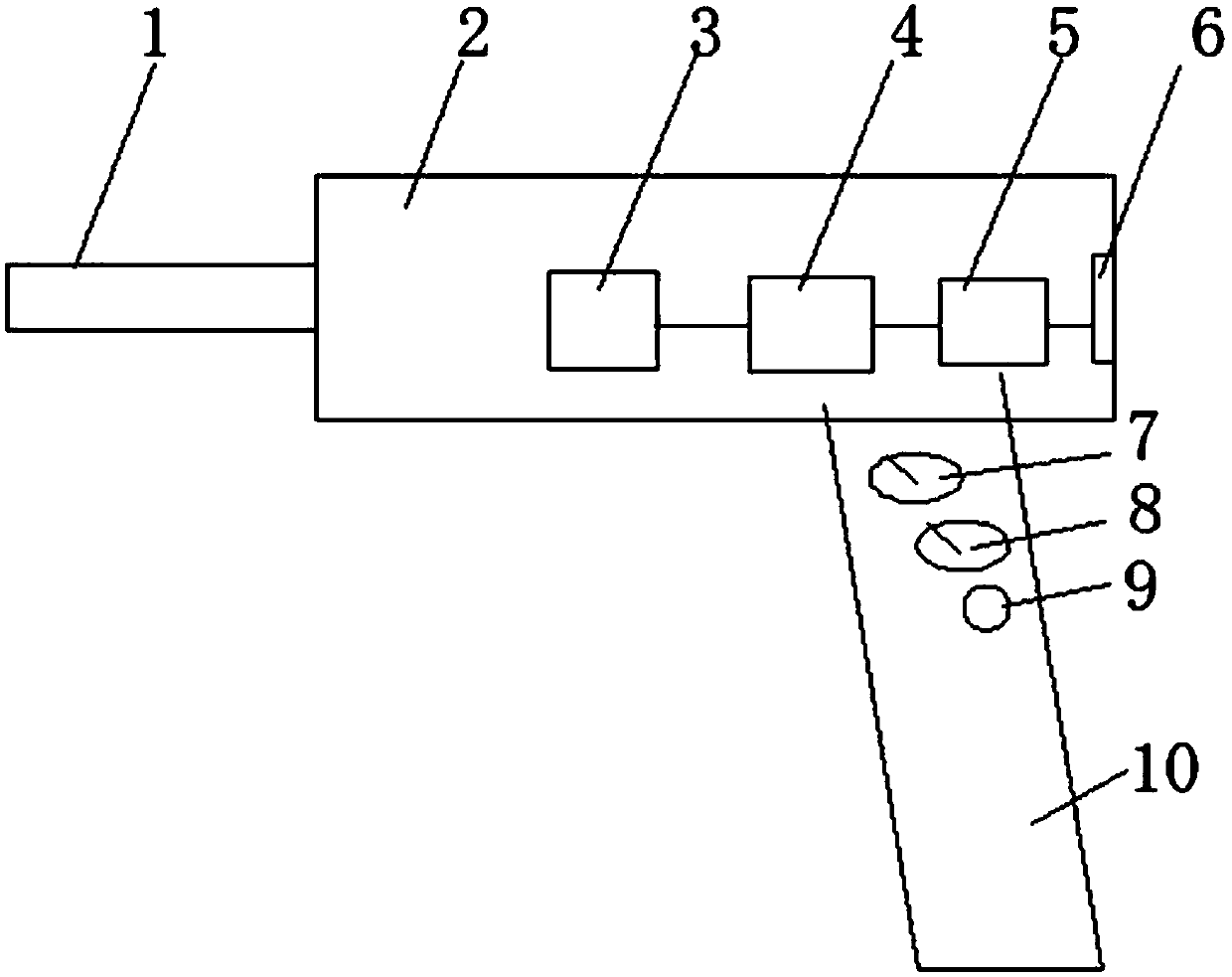

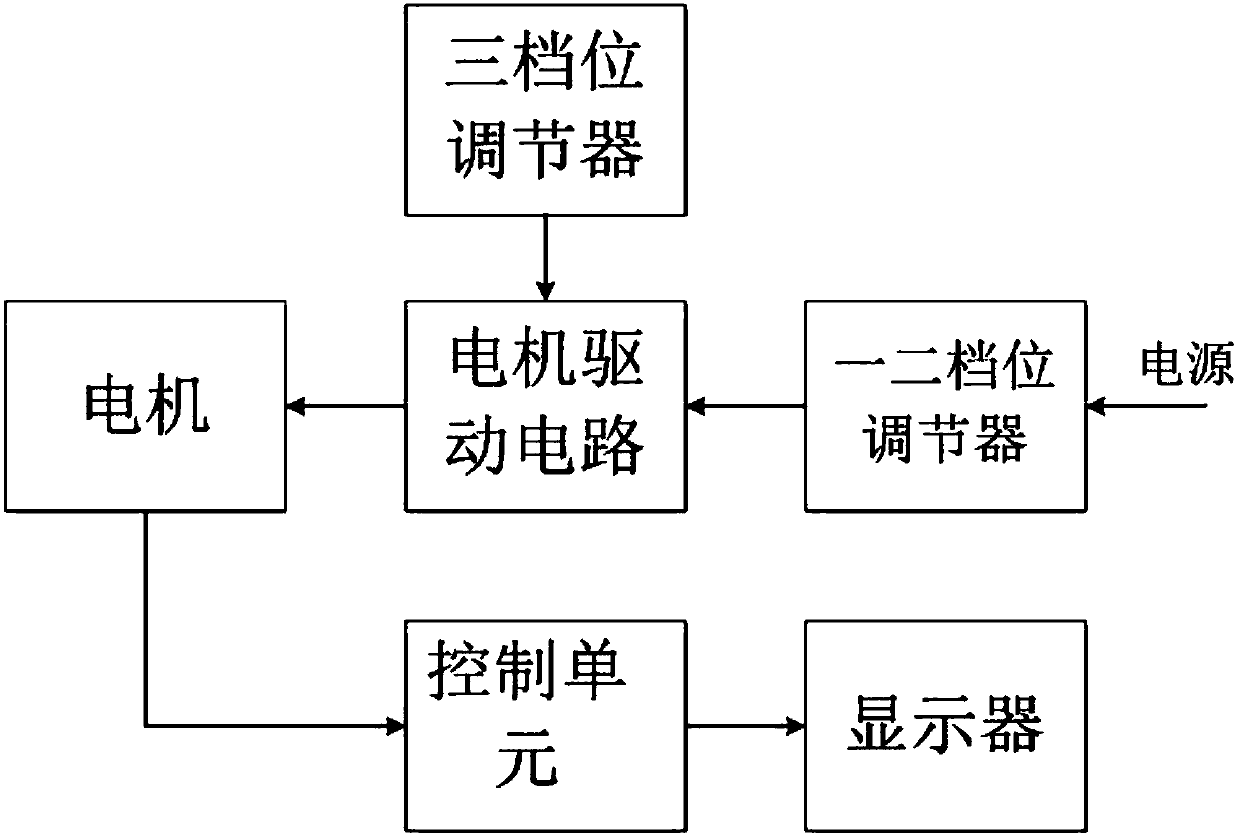

[0023] Such as figure 1 and figure 2 As shown, the present embodiment provides a step-by-step precision bone drill, which is shaped like a pistol and mainly includes an outer shell 2 and a handle 10 connected to the bottom of the outer shell. The outer shell 2 is provided with The drill bit 1, the stepper motor 3, the stepper motor drive circuit 4, the control unit 5 and the display 6 connected in sequence, wherein the front end of the drill bit 1 stretches out of the outer casing 2, and the display 6 is installed at the tail end of the outer casing 2, the operator can View some numerical information through the display screen at the rear of the outer casing; a gear adjuster is installed on the handle 10, and the gear adjuster is electrically connected with the stepper motor drive circuit 4, and the feed depth of the drill bit 1 is adjusted and controlled through the gear adjuster .

[0024] Wherein, the drill bit 1 is connected with the stepping motor 3 through a gear tran...

Embodiment 2

[0028] A kind of operation method of step-by-step precision feeding bone drill, utilizes the bone drill described in embodiment 1, and its specific operation process is as follows:

[0029] When in use, the operator holds the handle 10, drills the bone drill switch, and initially sets the bone drilling depth according to the approximate skull thickness obtained by the patient’s scan. Feed; then select different gear combinations, first use the large step gear (such as the first gear adjustment switch or the second gear adjustment switch) and then use the small step distance gear (the second gear adjustment switch or the second gear adjustment switch) Three-gear adjustment switch), by adjusting the corresponding gear multiple times to perform step feed until reaching the bone drilling depth, the drill bit 1 will perform the corresponding linear feed depth according to the selected gear, and will not cause excessive linear feed of the drill bit or too little. Using the bone dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com