High-pressure cleaning machine

A technology of a high-pressure cleaner and body, applied to cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., which can solve problems such as inconvenient storage and placement, inability to separate, and the cleaning machine does not have a self-priming function , to achieve the effect of convenient and quick use, time-saving and labor-saving assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

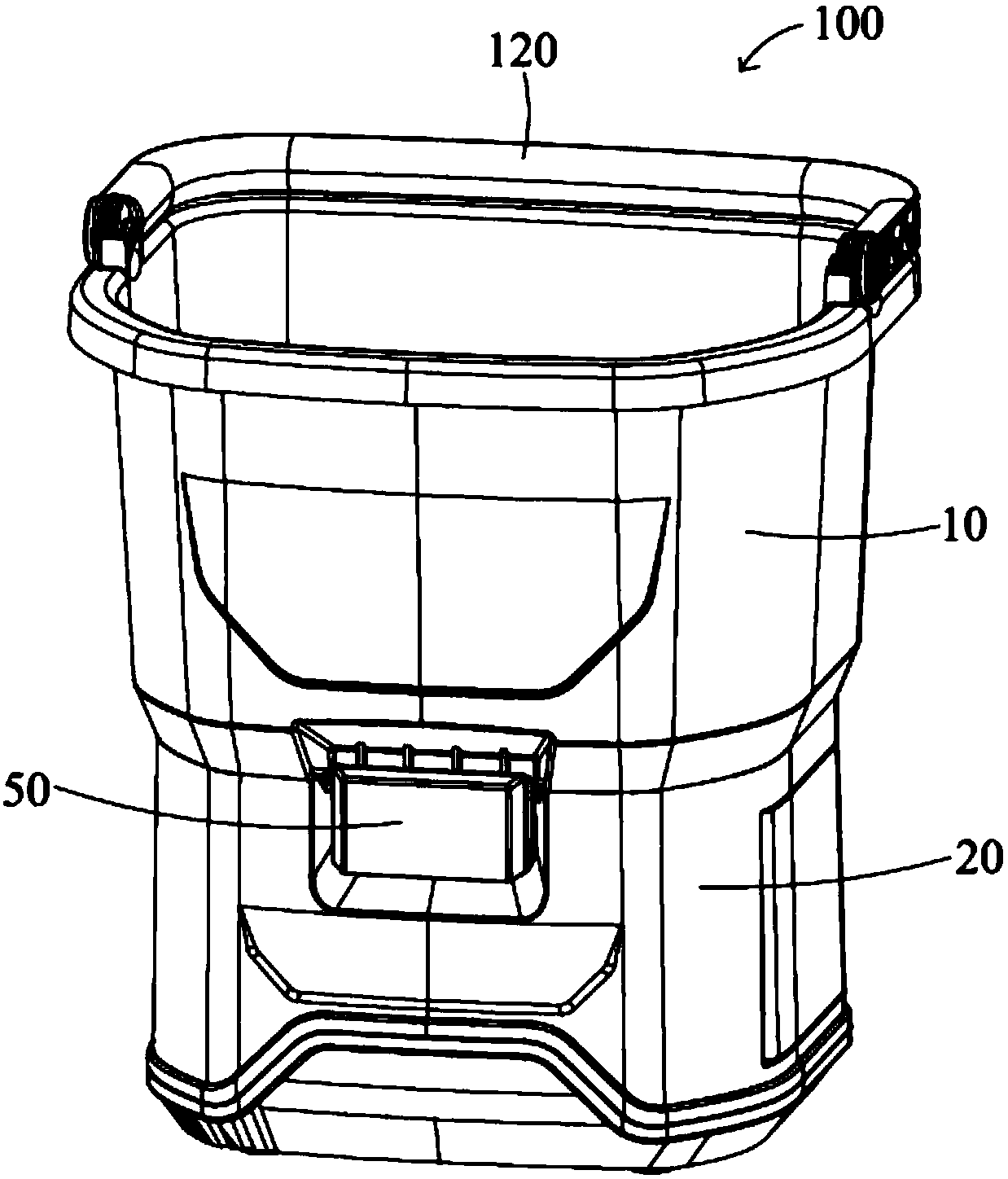

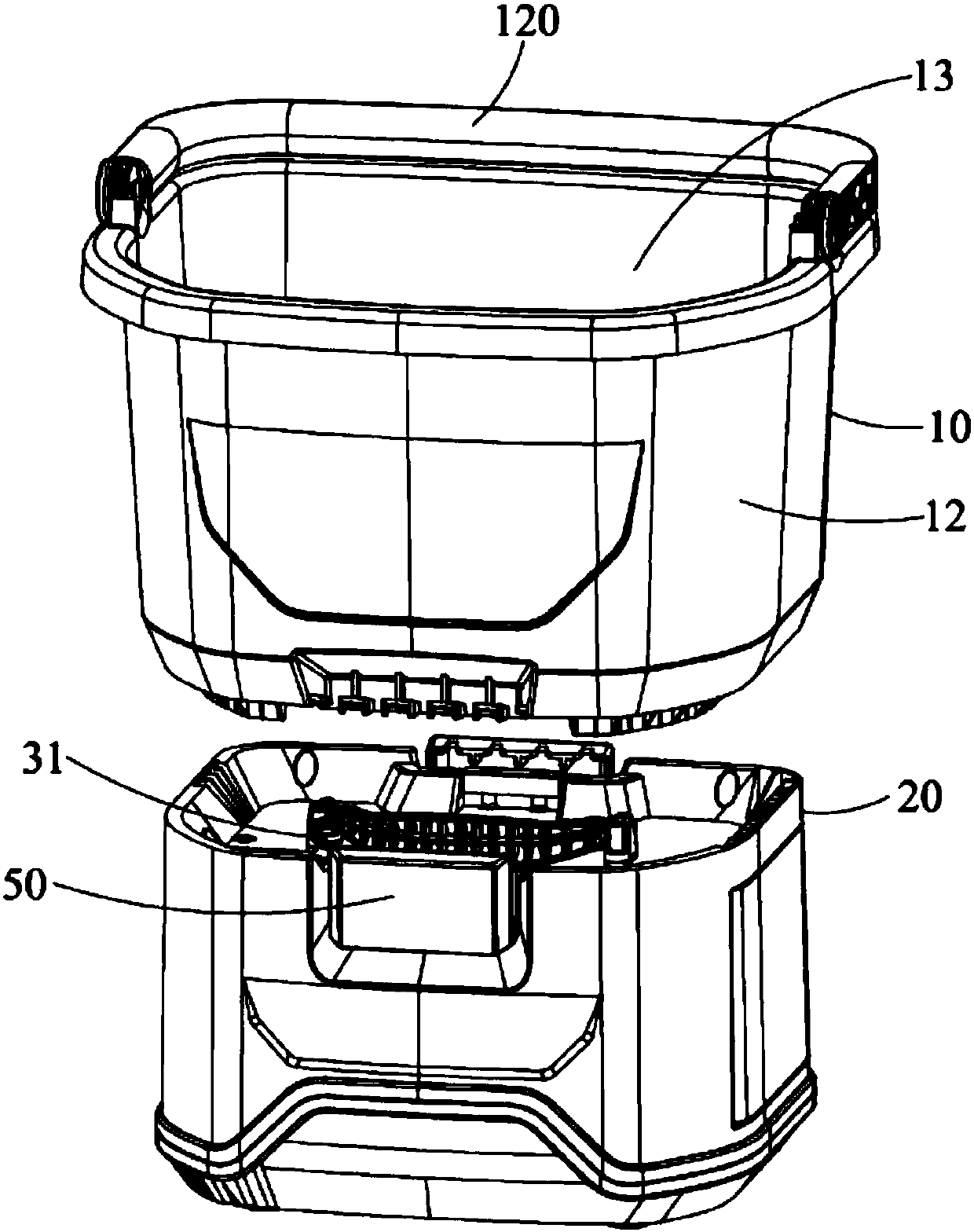

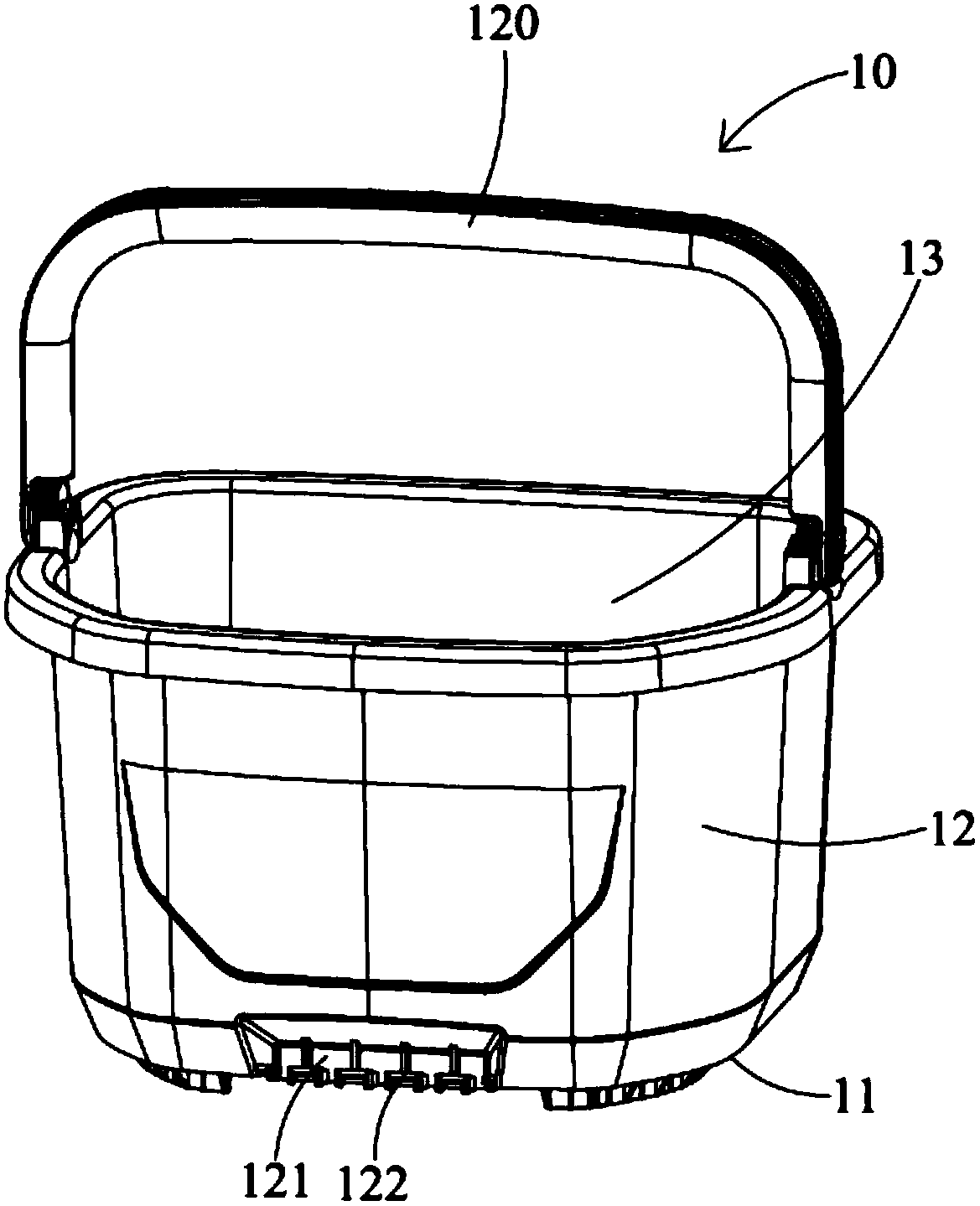

[0032] See Figure 1 to Figure 6 As shown, the present invention discloses a high-pressure washer 100, which includes a water storage device 10 and a body 20 disposed below the water storage device 10. The body 20 includes a casing 30, a water pump 40, and a power device (not shown) for driving the water pump 40 to work. (Shown) and a pair of buckle devices 50. The water pump 40 and the power device (not shown) are located in the casing 30. The buckle device 50 fixes the outside of the casing 30 for buckling the water storage device 10 on the body 20 . The power unit is a gasoline engine, a diesel engine, an induction motor, a series motor, a brush motor, a brushless motor or a DC motor.

[0033] The structure of the water storage device 10 is sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com