Deep blind hole housing body rapid measurement device and measurement and compensation machining methods

A technology of measuring device and processing method, which is applied to metal processing equipment, measuring/indicating equipment, metal processing mechanical parts, etc., can solve the problems of low processing accuracy, easy to tremble, and it is difficult for the radome to meet the electrical performance requirements. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

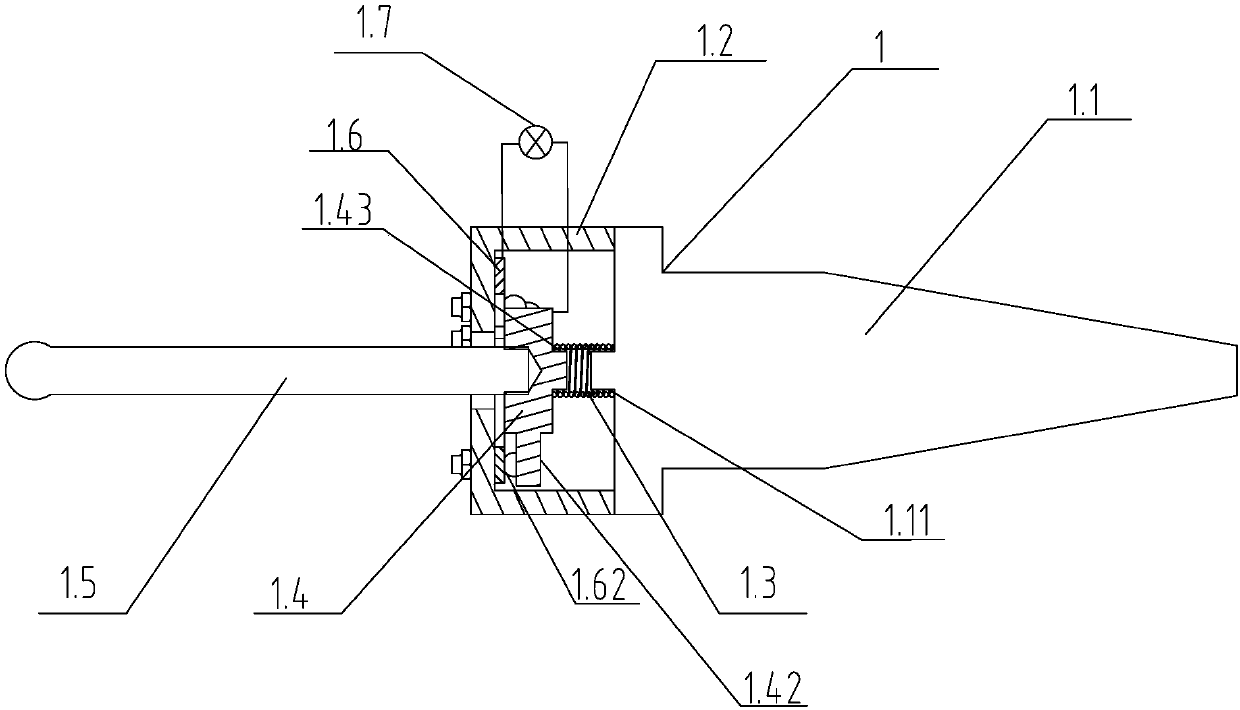

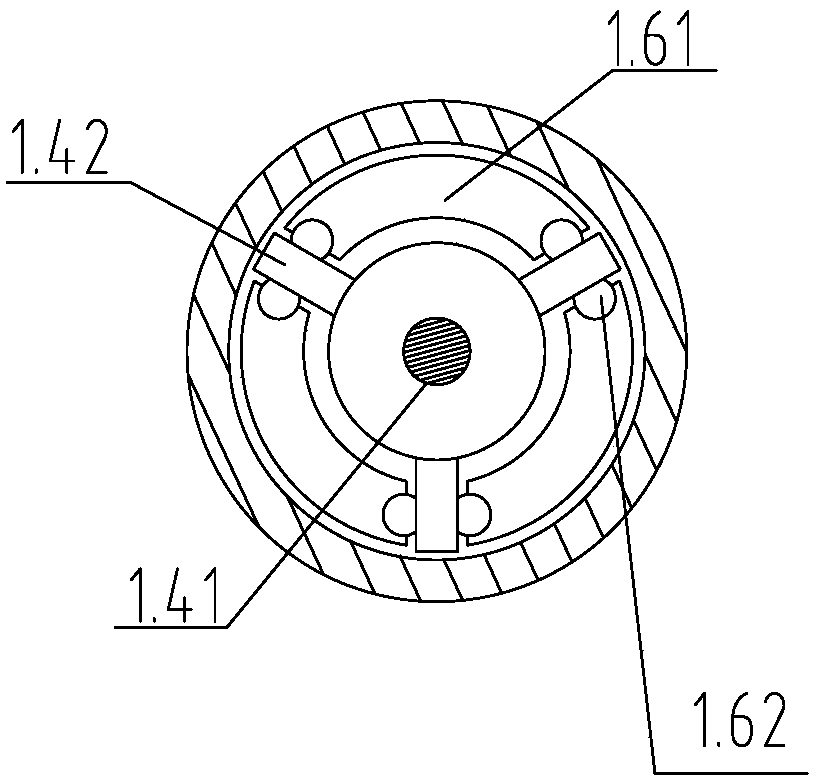

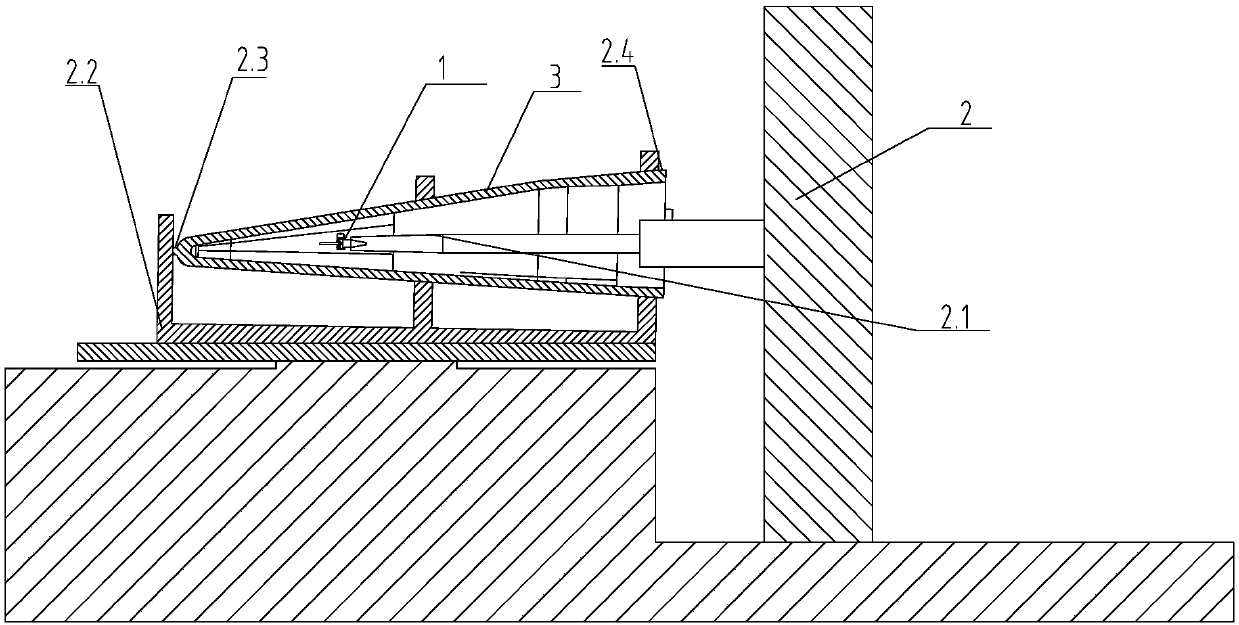

[0029] Such as figure 1 , figure 2 As shown, the deep blind hole cover rapid measuring device 1 of the present invention includes a base 1.1 coaxially arranged with the machine tool spindle 2.1, the rear end of the base 1.1 is a tapered structure, embedded in the machine tool spindle 2.1, and the front end is provided with a mounting cover 1.2, The installation cover 1.2 forms a cavity structure at the front end of the base 1.1, the front end of the inner cavity of the installation cover 1.2 is provided with a conductive plate 1.6, and the middle part of the installation cover 1.2 and the conductive plate 1.6 is provided with a through hole for the probe 1.5 to pass through. The front end of 1.5 is an arc surface, and the rear end passes through the mounting cover 1.2 and the conductive plate 1.6, and extends into the moving plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com