Luminous brick and preparation method thereof

A technology of luminescent fiber and long afterglow luminescence, which is applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of cumbersome optical fiber insertion and uniform distribution, positioning methods, unsatisfactory structural stability, and insufficient bearing capacity of bonded structures, etc. problems, to achieve the effects of simplified interspersion and uniform distribution, good oxidation resistance, and long luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

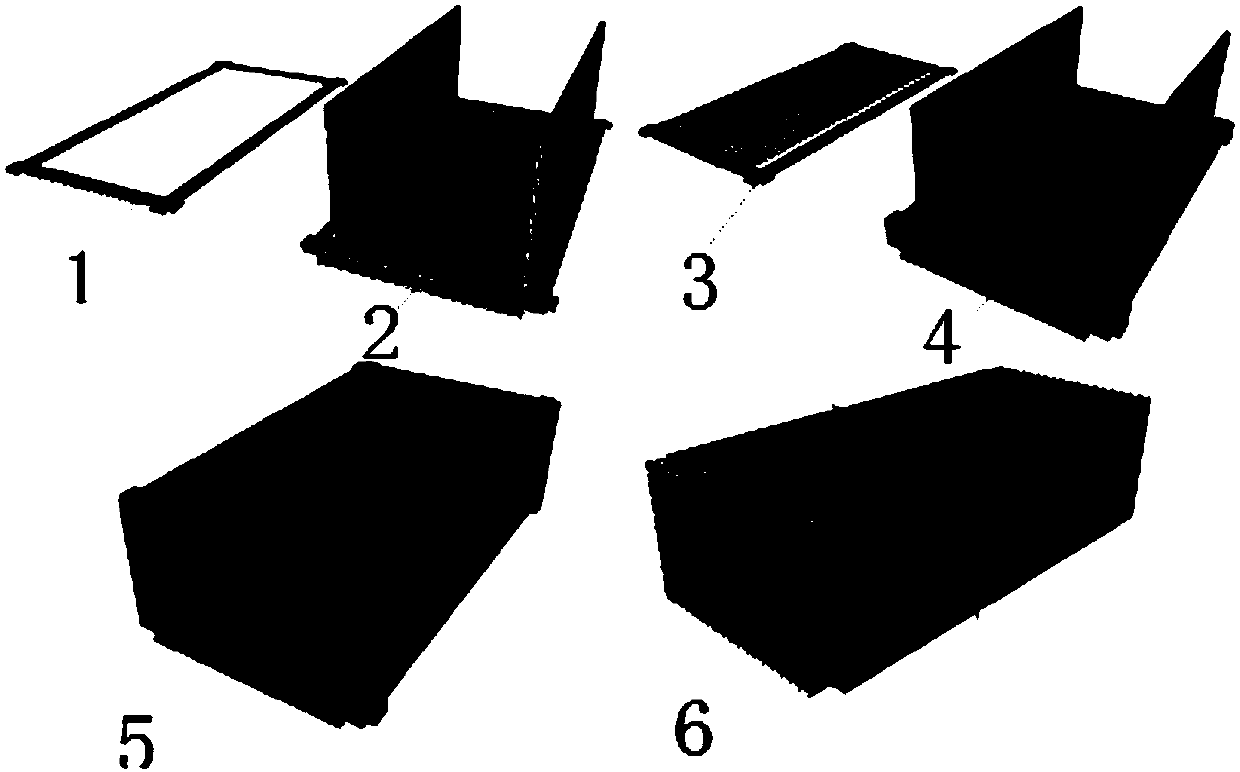

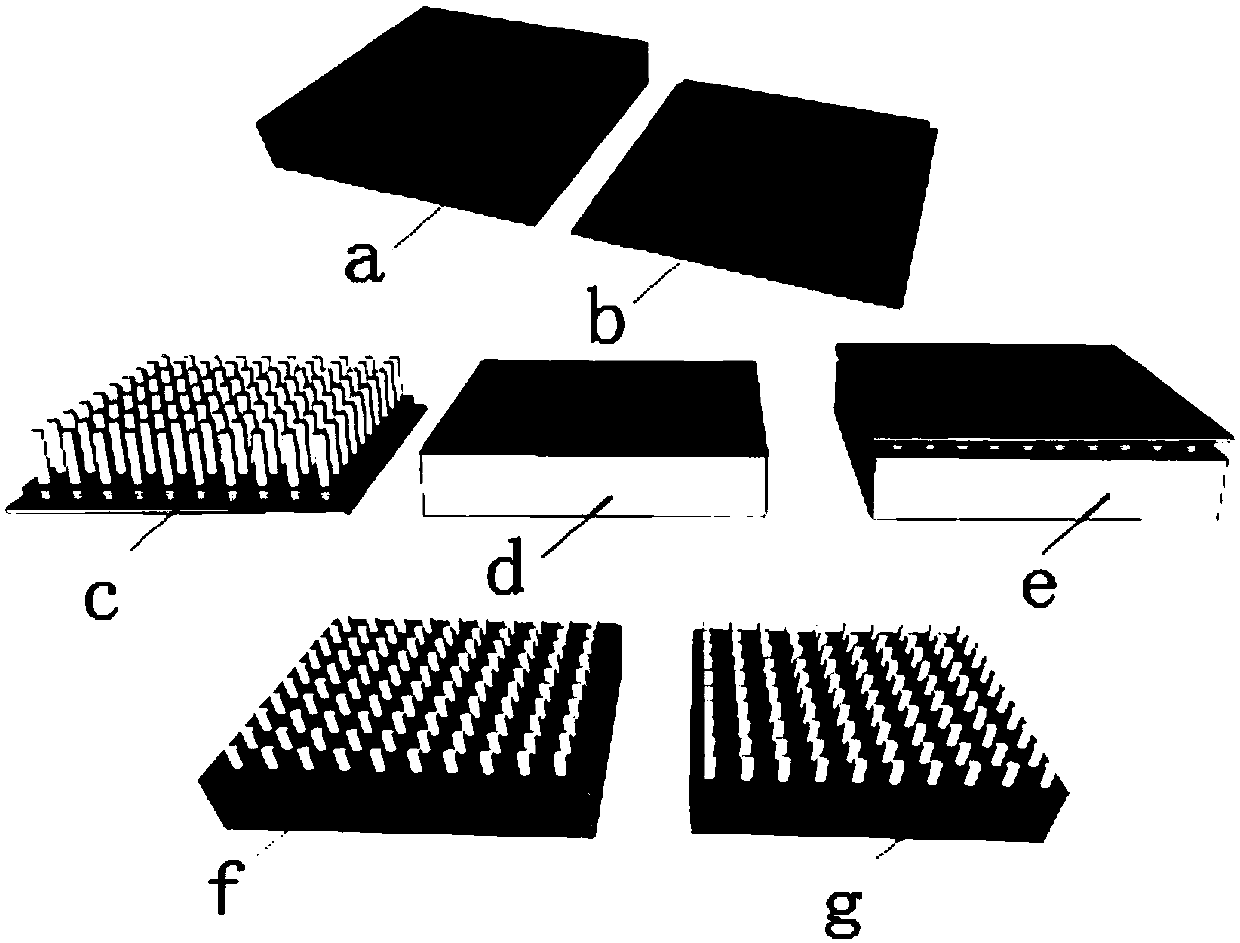

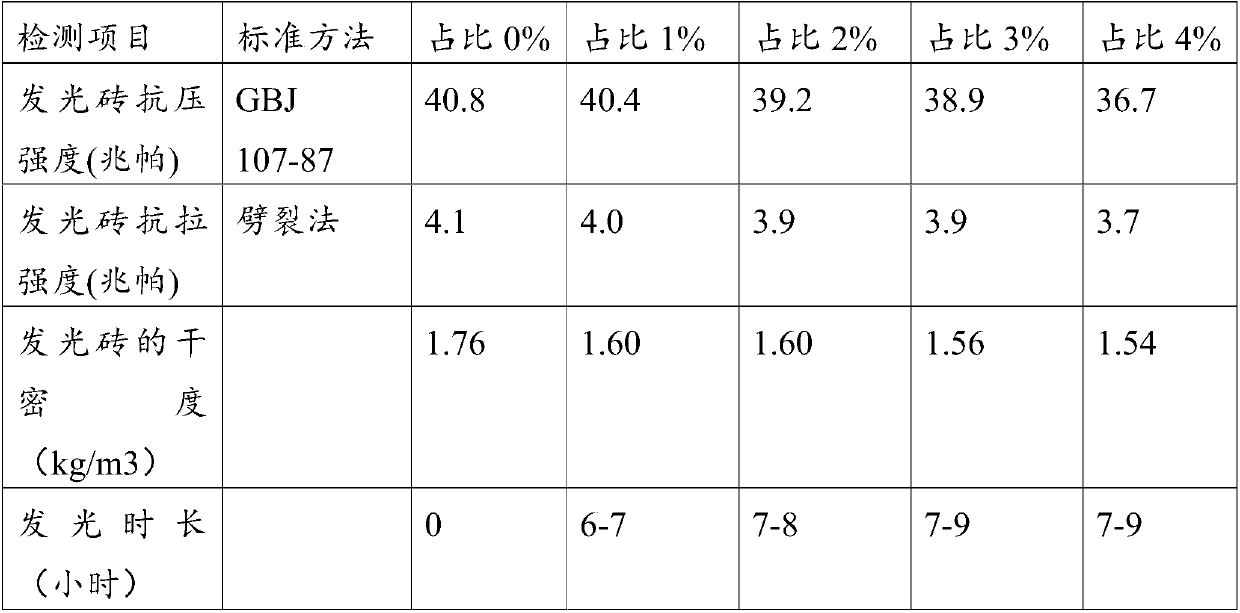

[0035] An embodiment of the luminescent brick of the present invention, the luminescent brick in this embodiment includes luminescent fibers and concrete, the luminescent fibers are uniformly arranged in the luminescent brick, and the luminescent fibers and the luminescent brick The decoration plane is vertical, and the luminous fiber is a rod-shaped structure with a diameter of 1-3mm.

[0036] Wherein, the luminous fiber contains the following components by weight: 100 parts of polymethyl methacrylate, 2 parts of long-lasting luminous coating material, 0.5 parts of lubricant, 1 part of dispersant, 2 parts of antioxidant; The coating material contains the following components in mass percentage: long-lasting luminescent material (Sr2MgSi2O7: Eu 2+, Dy3) 92%, polyethylene wax 8%; the long-lasting luminescent material and polyethylene wax are coated in a coating machine treatment to obtain the long-lasting luminous coating material.

[0037] This embodiment is a method for prep...

Embodiment 2

[0045] An embodiment of the luminescent brick of the present invention, the luminescent brick in this embodiment includes luminescent fibers and concrete, the luminescent fibers are uniformly arranged in the luminescent brick, and the luminescent fibers and the luminescent brick The decoration plane is vertical, the light-emitting fiber is a rod-shaped structure, and the diameter of the light-emitting fiber is 1-3mm.

[0046] Wherein, the luminous fiber contains the following ingredients in parts by weight: 100 parts of polymethyl methacrylate, 8 parts of long-lasting luminescent coating material, 1.5 parts of lubricant, 5 parts of dispersant, and 5 parts of antioxidant; The coating material contains the following components in mass percentage: 98% of long-lasting luminescent material (Sr2MgSi2O7: Eu 2+, Dy3), 2% of polyethylene wax; the long-lasting luminescent material and polyethylene wax are coated in a coating machine treatment to obtain the long-lasting luminous coating ...

Embodiment 3

[0055] An embodiment of the luminescent brick of the present invention, the luminescent brick in this embodiment includes luminescent fibers and concrete, the luminescent fibers are uniformly arranged in the luminescent brick, and the luminescent fibers and the luminescent brick The decoration plane is vertical, the light-emitting fiber is a rod-shaped structure, and the diameter of the light-emitting fiber is 1-3 mm.

[0056] Wherein, the luminous fiber contains the following ingredients in parts by weight: 100 parts of polymethyl methacrylate, 6 parts of long-lasting luminous coating material, 1 part of lubricant, 3 parts of dispersant, 3.5 parts of antioxidant; The coating material contains the following components in mass percentage: 95% long-lasting luminescent material (Sr2MgSi2O7: Eu 2+, Dy3), 5% polyethylene wax; the long-lasting luminescent material and polyethylene wax are coated in a coating machine treatment to obtain the long-lasting luminous coating material.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com