Compound of keratinase and application in industrial production

A technology of keratinase and compound enzyme, applied in the field of industrial biology, can solve the problems of leather collagen composition or integrity damage, etc., and achieve the effects of complete hair removal effect, good application prospect and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Application characteristics of embodiment 1 keratinase KERBP

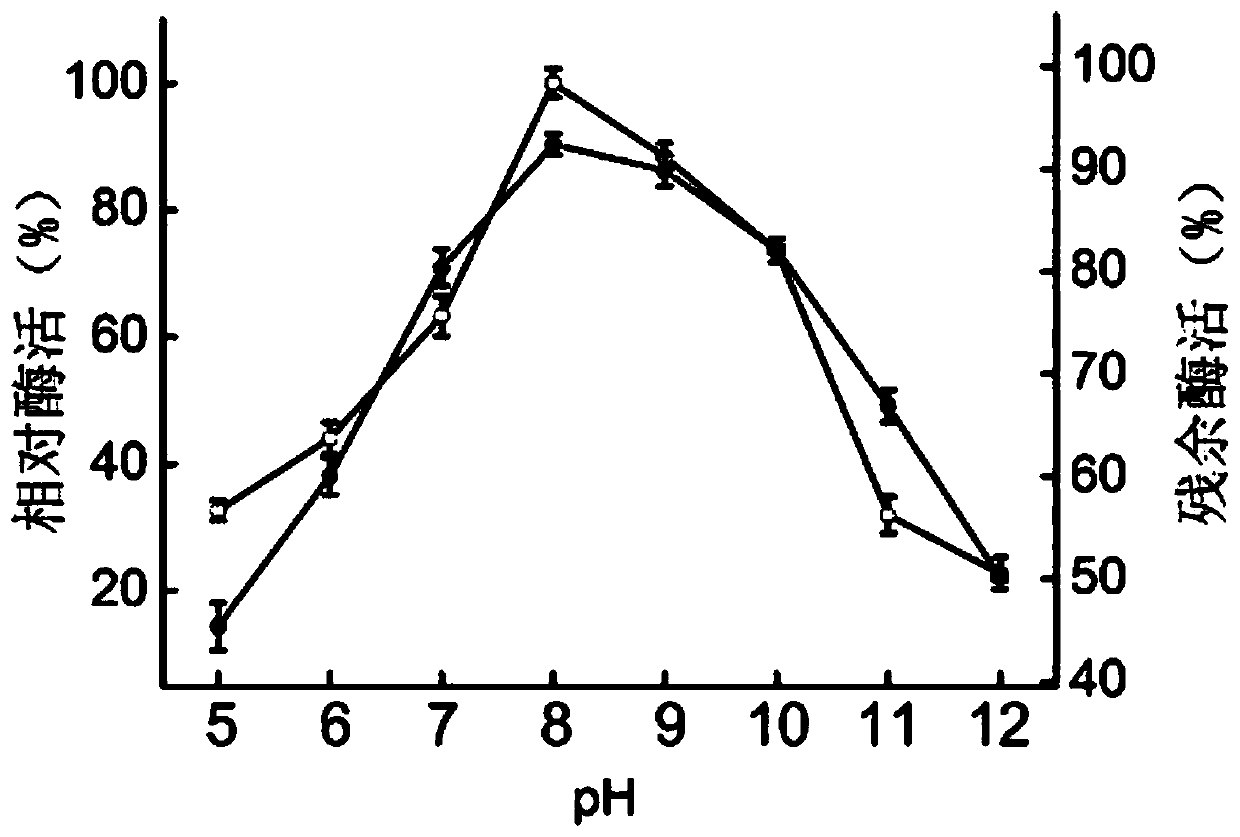

[0029] (1) Optimum pH and pH stability

[0030] The optimal reaction pH of KERBP is 8.0. With the continuous increase of pH, the enzyme activity of keratinase first increases and then decreases; the stable pH range of recombinant keratinase is 7.0-9.0, and the residual enzyme activity in this range is >75% , at pH11.0, the residual enzyme activity decreased rapidly. The results showed that after incubation for 1 hour in the pH range of 8.0-10.0, the enzyme activity was still high, indicating that the recombinant keratinase was more stable in the alkaline pH range. In the tanning process, the operating conditions of multiple production processes such as soaking, dehairing and liming are often alkaline, while the optimum reaction pH of recombinant keratinase is alkaline, which is suitable for the tanning process.

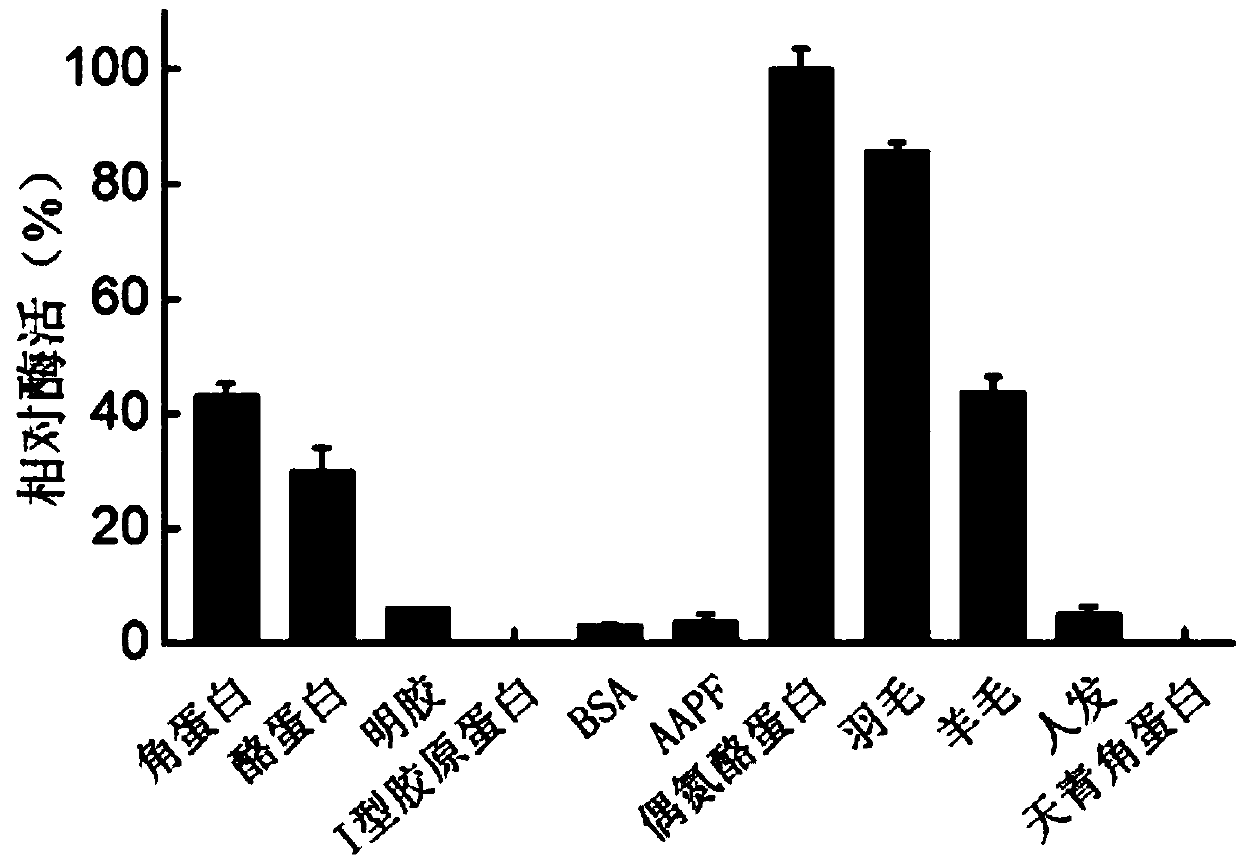

[0031] (2) Effect of chemical reagents on keratinase activity

[0032] Under the reaction con...

Embodiment 2

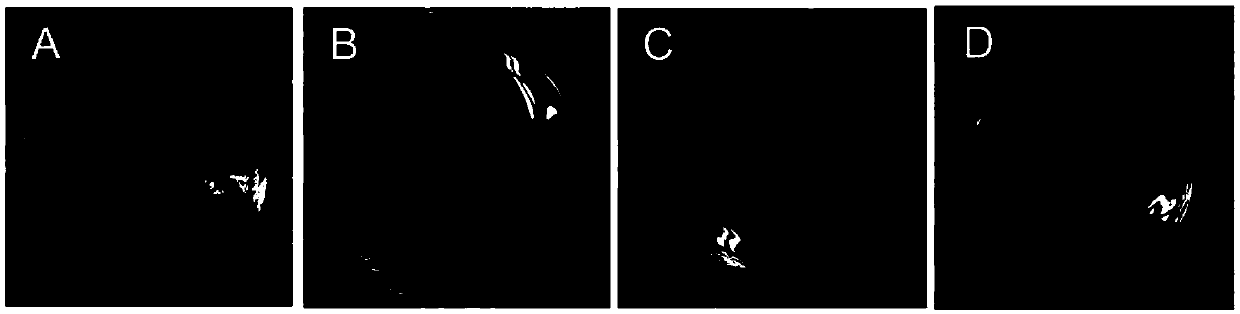

[0046] Embodiment 2 Recombinant keratinase is applied to the depilation of sheepskin

[0047] The amount of keratinase is 10000U / 50mL, mixed with raw sheepskin of about 6cm×6cm size (equivalent to 278U / cm2 raw sheepskin), and shaken and reacted at 37°C and 200rpm. A commercial depilatory protease derived from Bacillus was selected as a positive control for enzymatic hair removal, and its dosage was the same as that of the recombinant keratinase KERBP in the hair removal method.

[0048] The above treatment results show that without using heavily polluted chemical reagents such as sulfide, keratinase and sheepskin can be completely depilated after 9 hours of co-incubation. The wool was not removed when the negative control was mixed with water and sheepskin; compared with the sheepskin depilated by chemical method, the color was heavier and the touch was harder, and the sensory test showed that the sheepskin depilated by recombinant keratin was lighter in color, smoother and so...

Embodiment 3

[0050] The depilatory effect under the different conditions of embodiment 3

[0051] The hair removal process mainly includes degrading the epidermis, hydrolyzing the intercellular mucin in the dermal hair follicle, damaging the link between the hair root and the hair follicle, causing the cells to separate from each other, weakening the root sheath and losing the wrapping effect on the hair root, and then the hair can be restored. detach from the hair follicle. Therefore, in this process, the enzymes in the skin must first penetrate into the junction of the epidermis until the dermis reaches the junction with the root sheath, hair papilla and hair bulb to achieve the depilatory effect. Adopt the addition amount of table 1 to carry out depilation. Select lipase, put about 6 cm×6 cm raw sheepskin into the compound enzyme solution (50 mL), shake and react at 37°C and 200 rpm.

[0052] Through the sensory evaluation of the hair removal process and hair removal effect, the resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com