Rotatable and multifunctional road maintenance equipment

A road maintenance and multi-functional technology, applied in the field of indexable multi-functional road maintenance equipment, can solve problems such as hidden dangers, excessive dust, power optimization, etc., and achieve the effect of safe construction process, high degree of intelligence, and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific content of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

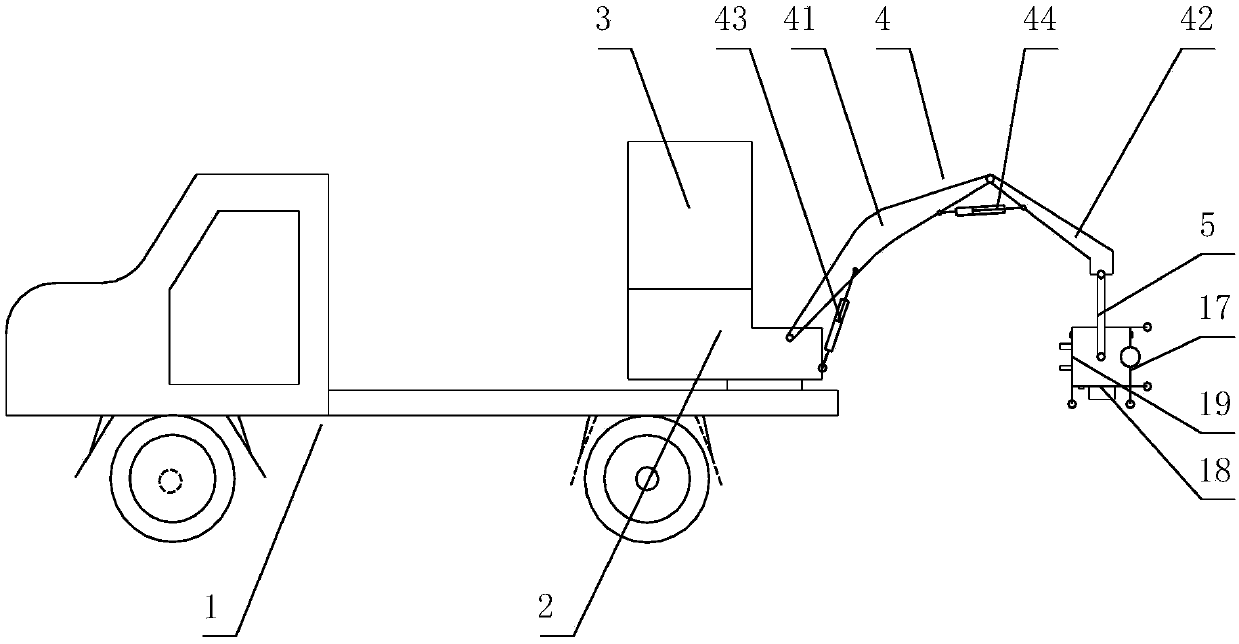

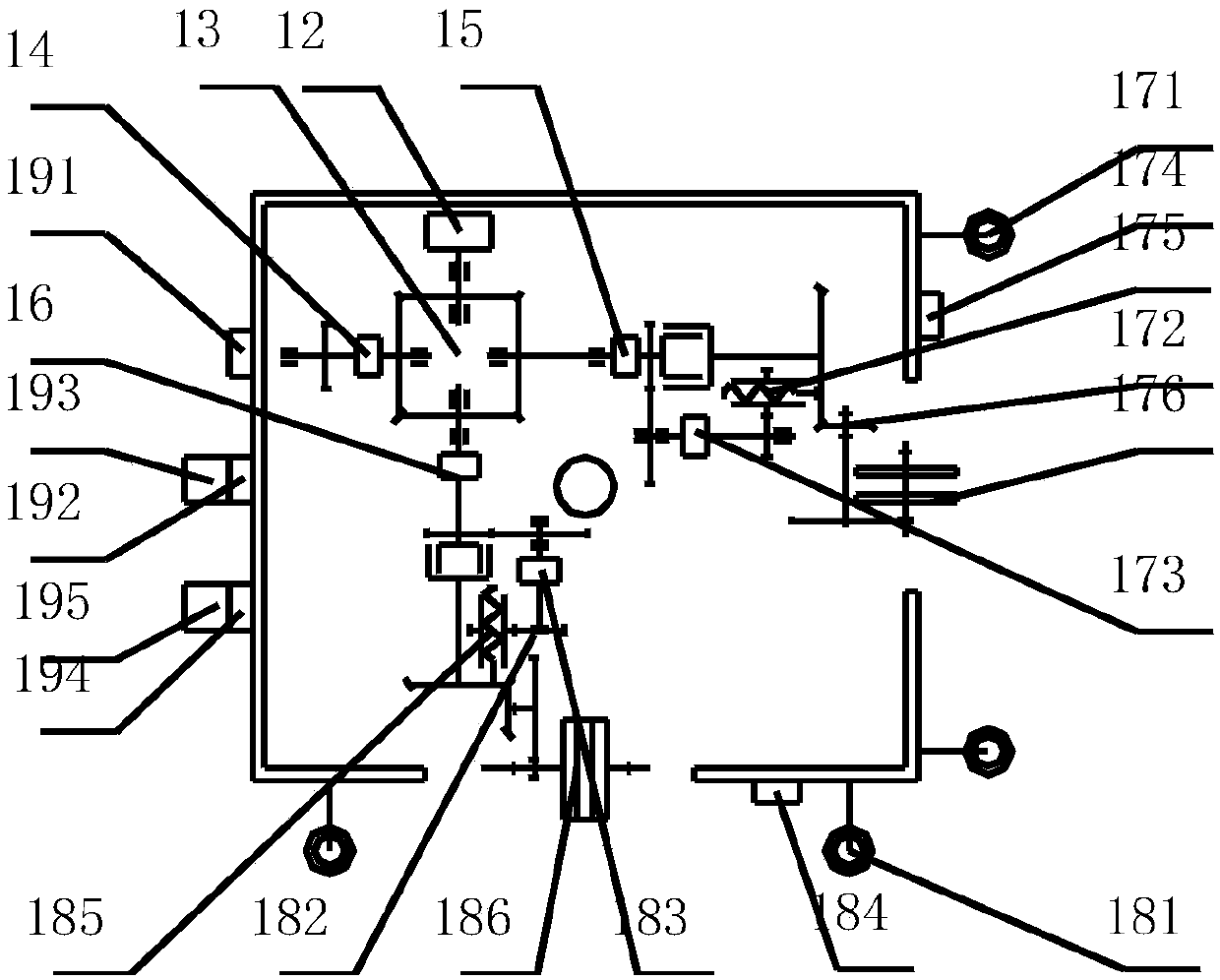

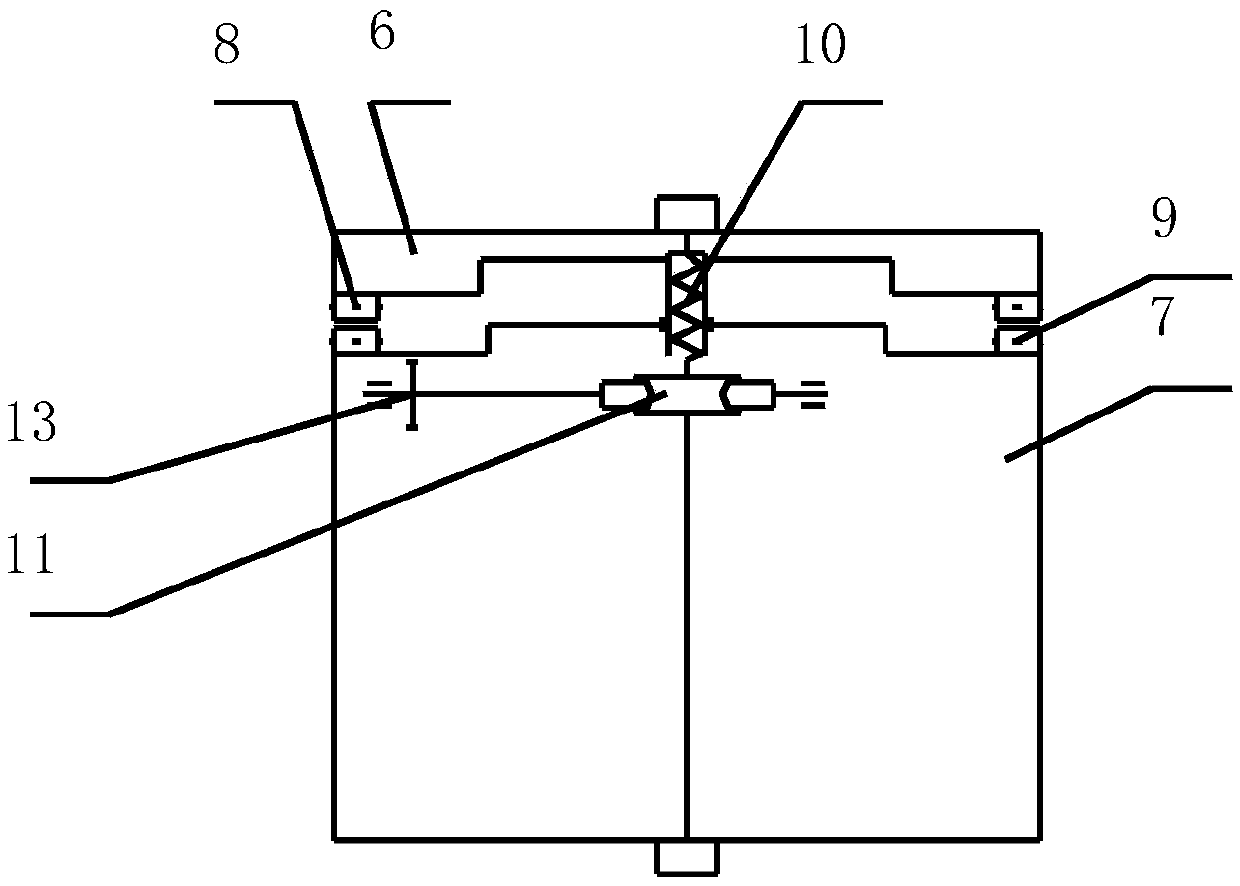

[0027] figure 1 It is a schematic diagram of the structure of the maintenance equipment of the present invention installed on the road maintenance vehicle. In the figure, the balance turntable 2 is installed on the chassis 1 of the maintenance vehicle, which is a commonly used rotary platform structure. The control system 3 is installed on the top of the balance turntable 2 to realize the automatic control of the entire machine tool. The articulated mechanical arm 4 is articulated at the side of the balance turntable 2. The articulated robot arm 4 of this embodiment includes a first arm 41 and a second arm 42. The first arm 41 is connected to the balance turntable 2 through a first hydraulic cylinder 43. A hydraulic cylinder 43 controls the amplitude of the first arm 41, the second arm 42 is connected with the first ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap