Protective rib template for cast-in-place reinforced concrete beam column

A reinforced concrete and protective technology, which is applied in the field of cast-in-place reinforced concrete beam-column protective rib formwork, can solve the problems of low cement hydration gel strength of beam-column, poor guarantee of beam-column accuracy, and affecting beam-column durability. , to achieve the effects of clean construction, convenient transportation, construction and installation, and improvement of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

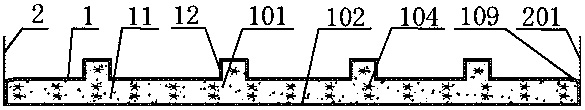

[0034] Example 1

[0035] Such as figure 1 As shown, a protective rib template for beams and columns made of cement mortar, fiber cloth, and fiber ropes mainly includes a rigid fiber mortar rib template 1 and a connecting member 2. The rigid fiber mortar rib template 1 includes Flat ribs 11 and ribs 12, ribs 12 are fixed parallel to the inner surface of the flat ribs 11; the flat ribs 11 and ribs 12 are made of cement mortar 101 and polyester fiber cloth 102, polyester The fiber rope 104 is integrated by an extrusion molding process. The polyester fiber cloth 102 is firmly combined with the cement mortar 101 and covered on the surface of the rigid fiber mortar rib template 1. The polyester fiber rope 104 is arranged longitudinally in the cement mortar 101. The density of fiber rope 104 arranged perpendicular to the cross section is 2 / 1000mm 2 ; The width of the flat rib 11 is 800mm, the length is 1500mm, the thickness is 15mm, the thickness of the rib 12 is 15mm, the thickness of...

Example Embodiment

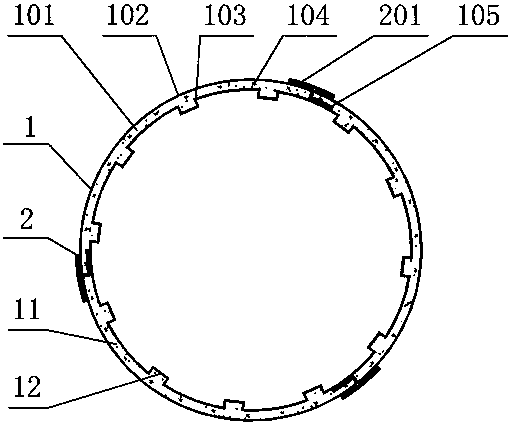

[0036] Example 2

[0037] Such as figure 2 As shown, a protective rib template frame for circular columns with straps made of cement mortar, fiber cloth, fiber mesh, and fiber ropes includes three protective rib templates for circular columns. The protective rib template for a circular column mainly includes a rigid mortar rib template 1 and a connecting member 2. The rigid mortar rib template 1 mainly includes an arc-shaped rib 11 and a rib 12, and the rib 12 is perpendicular to the cross section and fixed in parallel. The inner surface of the arc-shaped ribs 11; the arc-shaped ribs 11 and the ribs 12 are made of cement mortar 101, polyester fiber mesh 103, bamboo fiber cloth 102, and polyester fiber rope 104, which are integrated by a molding process The polyester fiber mesh 103 and the cement mortar 101 are firmly combined on the inner side of the rigid mortar rib template 1, the bamboo fiber cloth 102 and the cement mortar 101 are firmly combined on the outer side of the rig...

Example Embodiment

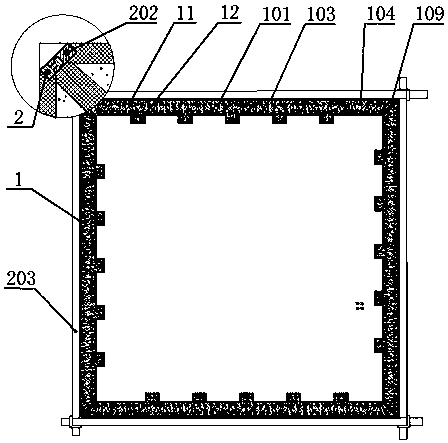

[0038] Example 3

[0039] Such as image 3 As shown, a protective rib template frame for columns made of fiber cement mortar, fiber mesh, and fiber ropes includes 4 protective rib templates for columns, and the protective rib templates for columns mainly include rigid The fiber mortar rib template 1 and the connecting member 2. The rigid fiber mortar rib template 1 includes a flat-shaped rib 11 and a rib 12, and the rib 12 is fixed on the inner surface of the flat-shaped rib 11 in parallel; The flat ribs 11 and the ribs 12 are made of fiber cement mortar 101, cotton fiber mesh 103, and cotton fiber rope 104 through a casting molding process. The cotton fiber network 103 and fiber cement mortar 101 are firmly combined and wrapped. Covered on the surface of the rigid fiber mortar rib template 1, the polyester fiber ropes 104 are arranged in the fiber cement mortar 101 longitudinally and laterally. The density of the polyester fiber ropes 104 perpendicular to each section is 100 roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com