Handheld capacity calibration device of liquid transferring machine and calibration method thereof

A technology for calibrating devices and pipettes, which is applied in the field of pipettes, can solve problems such as waste, repetitive operation steps, and cost hindering application, and achieve the effects of eliminating influence, reducing errors, and reducing repeated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

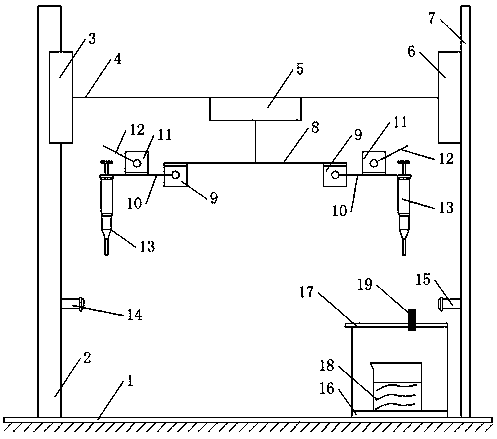

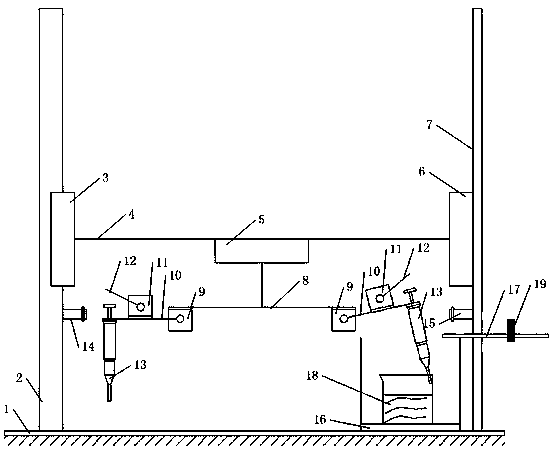

[0032] A handheld pipette capacity calibration device, which consists of the following components: upper computer, experimental platform 1, electric sliding table 2, first bracket 4, linear track 7, electric turntable 5, second bracket 8, first motor 9 , The third bracket 10, the second motor 11, the guide rod 12, the photoelectric switch transmitter 14, the photoelectric switch receiver 15, the electronic balance 16, the container 18, and the infrared temperature sensor 19. The electric sliding table 2, the electric turntable 5, the first motor 9, and the second motor 11 are respectively connected to the upper computer through the mechanical drive module, the infrared temperature sensor 19 is connected to the upper computer through the data acquisition card, and the electronic balance 16 is connected through the serial port Connect with the host computer.

[0033] The electric sliding table 3 is fixed on the left side of the experiment platform 1, the first sliding block 3 is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com