Quantitative characterization method for sulfur corrosion degree in transformer oil

A quantitative characterization and transformer oil technology, applied in the direction of removing certain components and weighing, can solve problems such as complex operations, and achieve the effects of simple and easy operation, wide application range, and strong practical application significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

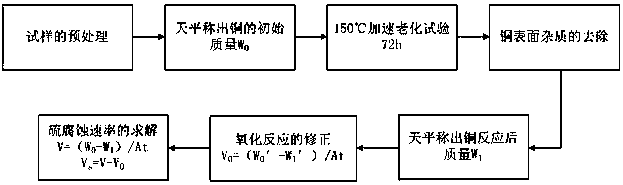

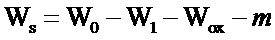

[0018] A method for quantitatively characterizing the degree of sulfur corrosion in transformer oil, said method comprising the steps of pretreatment of the test, carrying out of the aging test, removal of impurities on the surface of the copper sheet, correction of the influence of the oxidation reaction, and calculation of the sulfur corrosion rate;

[0019] in,

[0020] (1) Pretreatment of the test: polish the copper sheet to ensure that the roughness of each surface is consistent, wash with pure water and then wipe with alcohol, and finally air dry and weigh;

[0021] (2) Aging test: put the sample in a blast drying oven, and control the temperature at 150°C±2°C for accelerated aging for 72 hours;

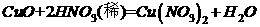

[0022] (3) Removal of impurities on the surface of copper sheets: use petroleum ether to remove residual oil stains on the surface of copper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com