Disc blank for producing commutator laminations

A technology for commutator segments and blanks, which is applied in the field of contact materials and can solve the problems of increased wear and adverse effects of carbon brushes and commutator segments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

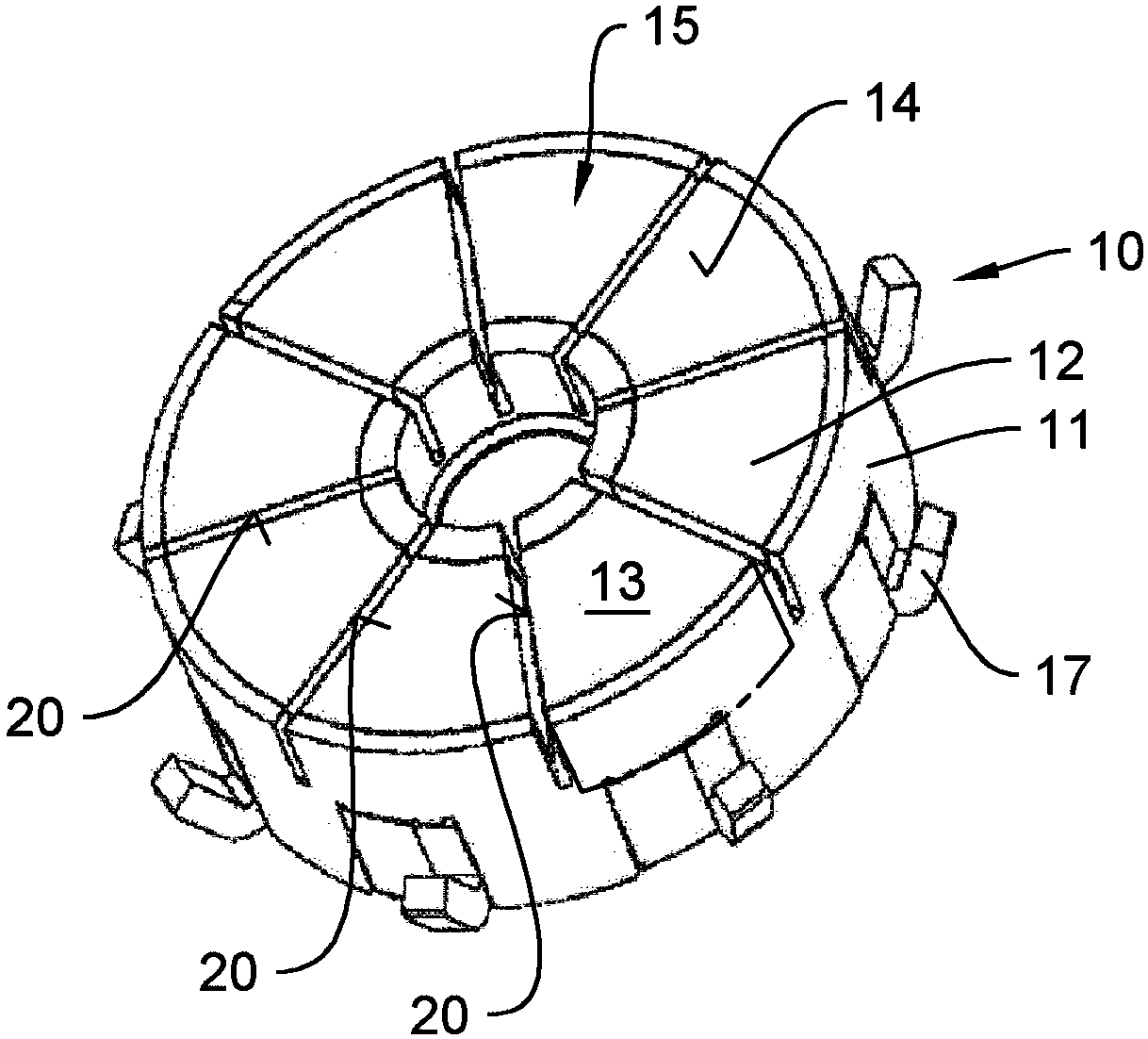

[0029] figure 1 Shown is a disc commutator 10 with a carrier body 11 made of non-conductive plastic and comprising, in the example of the embodiment shown, eight commutator segments 12 each arranged On the carrier body 11 such that the running surface parts 13 of the commutator segments 12 and their contact surfaces 14 are arranged in a shared contact plane 15 of the disk commutator 10 and can be connected in this contact plane 15 with the not shown here carbon brush contacts.

[0030] as from Figure 4 As can be seen in , which shows the commutator segments in a bottom view, the commutator segments 12 each comprise a contact body 16 on the underside of the running surface part 13 which forms the connection of the commutator segments 12 part and with figure 1 The shown hook-shaped outer contacts 17 are in contact, respectively for contacting or receiving the windings of the electric motor.

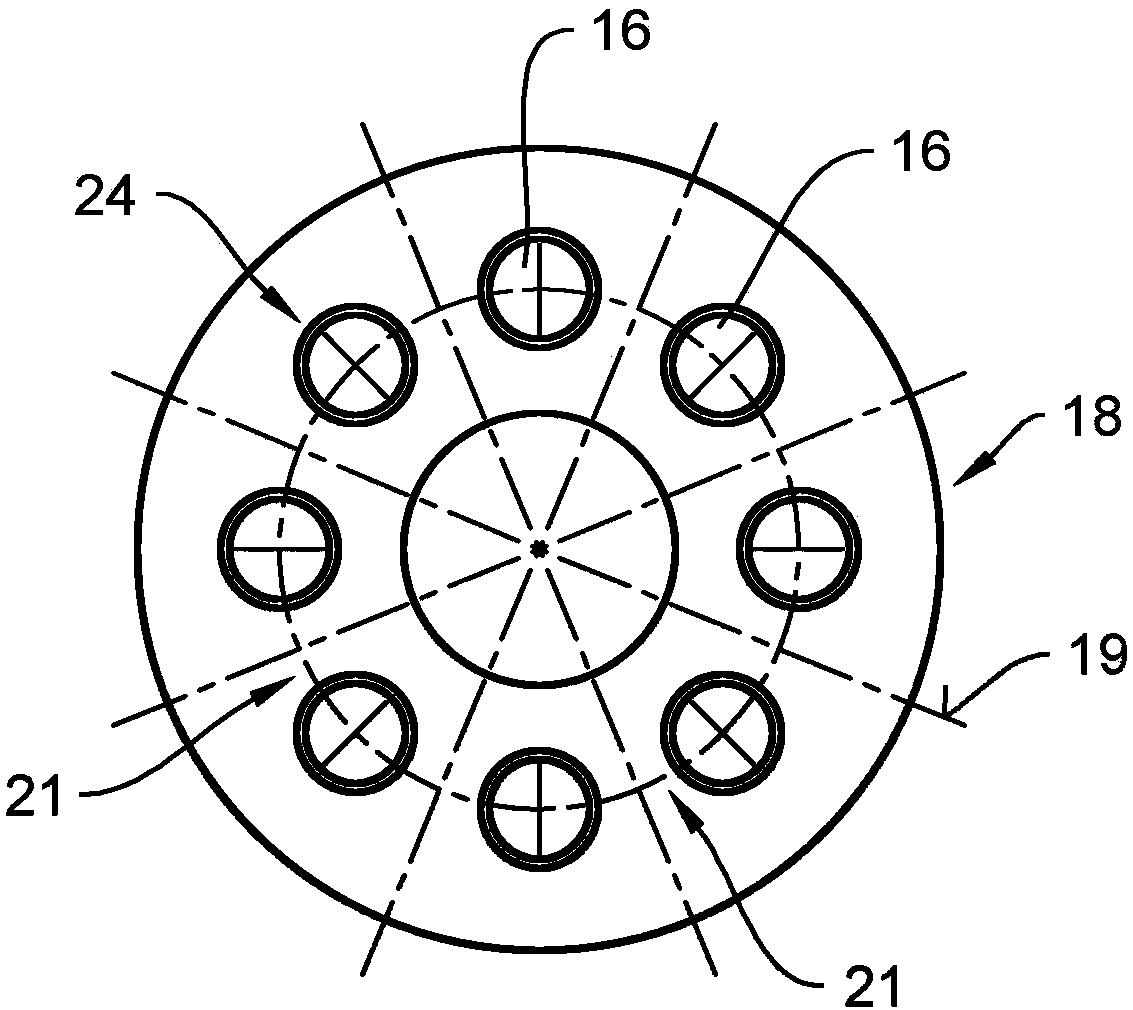

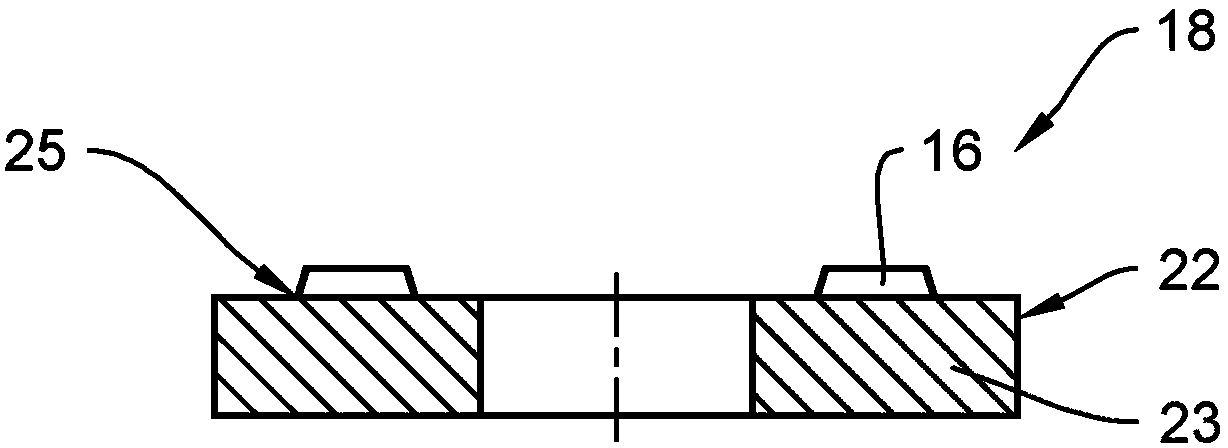

[0031] exist figure 2 and image 3 , a disc-shaped blank 18 is shown for manufa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com