Stirring feeder

A technology of mixing motor and mixing box, which is applied in mixers with rotating mixing devices, animal feeding devices, mixers, etc., can solve the problem of small contact area between blades and materials, wear of intermediate auger blades, and large coarse feed chopped particle size. and other problems, to achieve the effect of improving the kneading and cutting efficiency, slowing down the conveying capacity, and increasing the probability of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

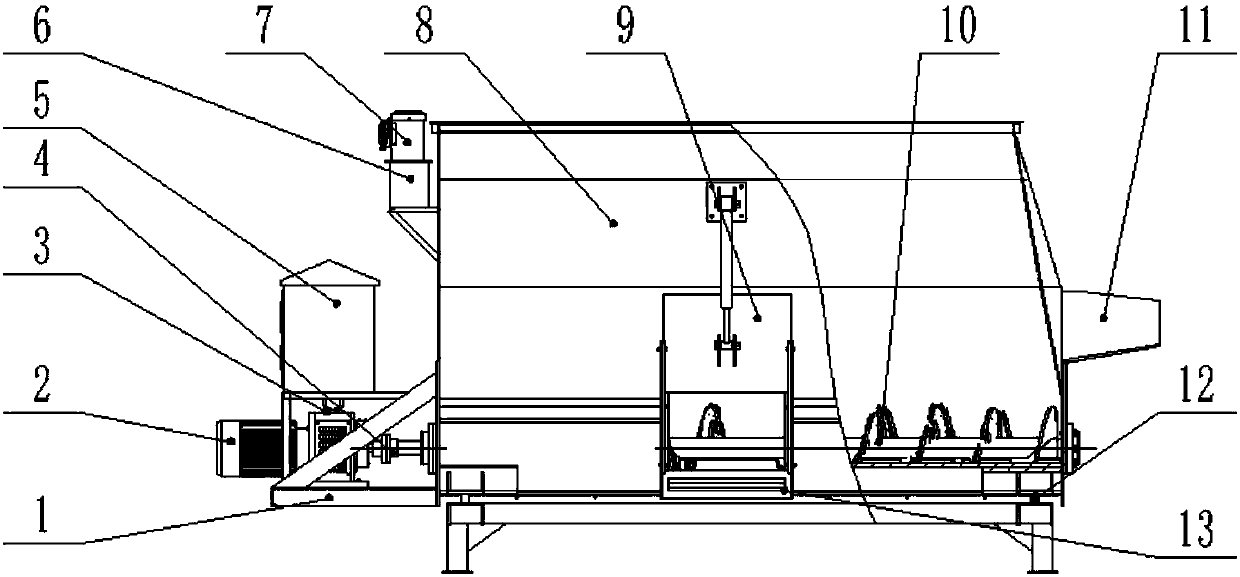

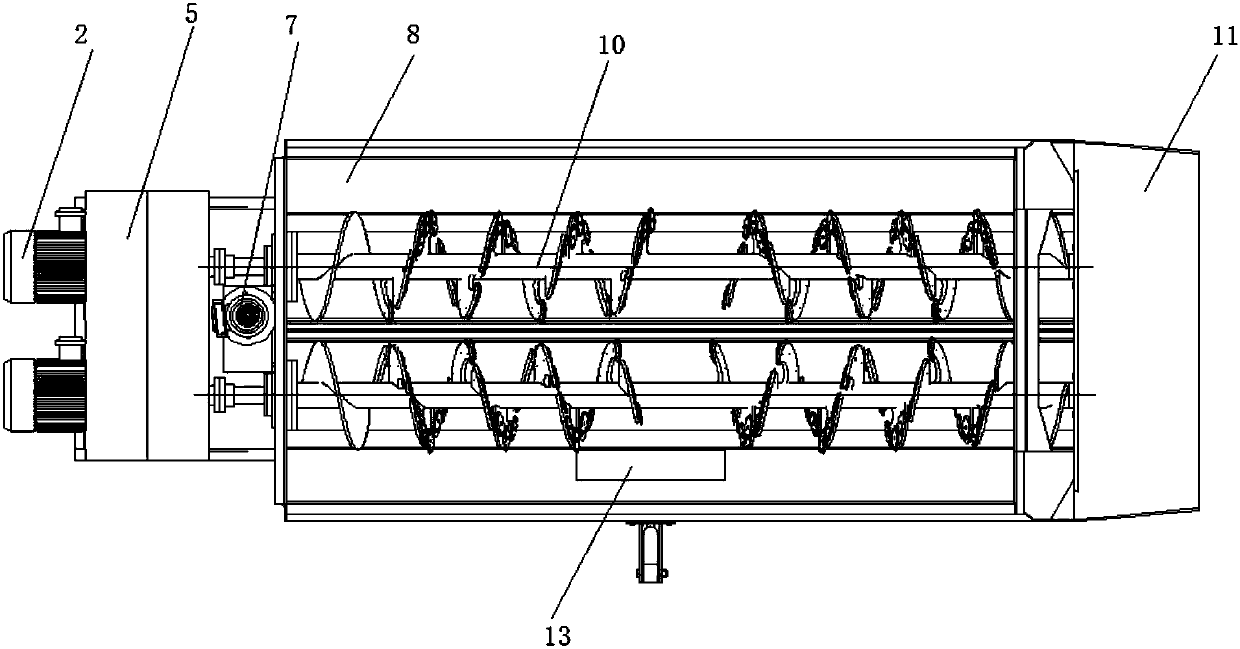

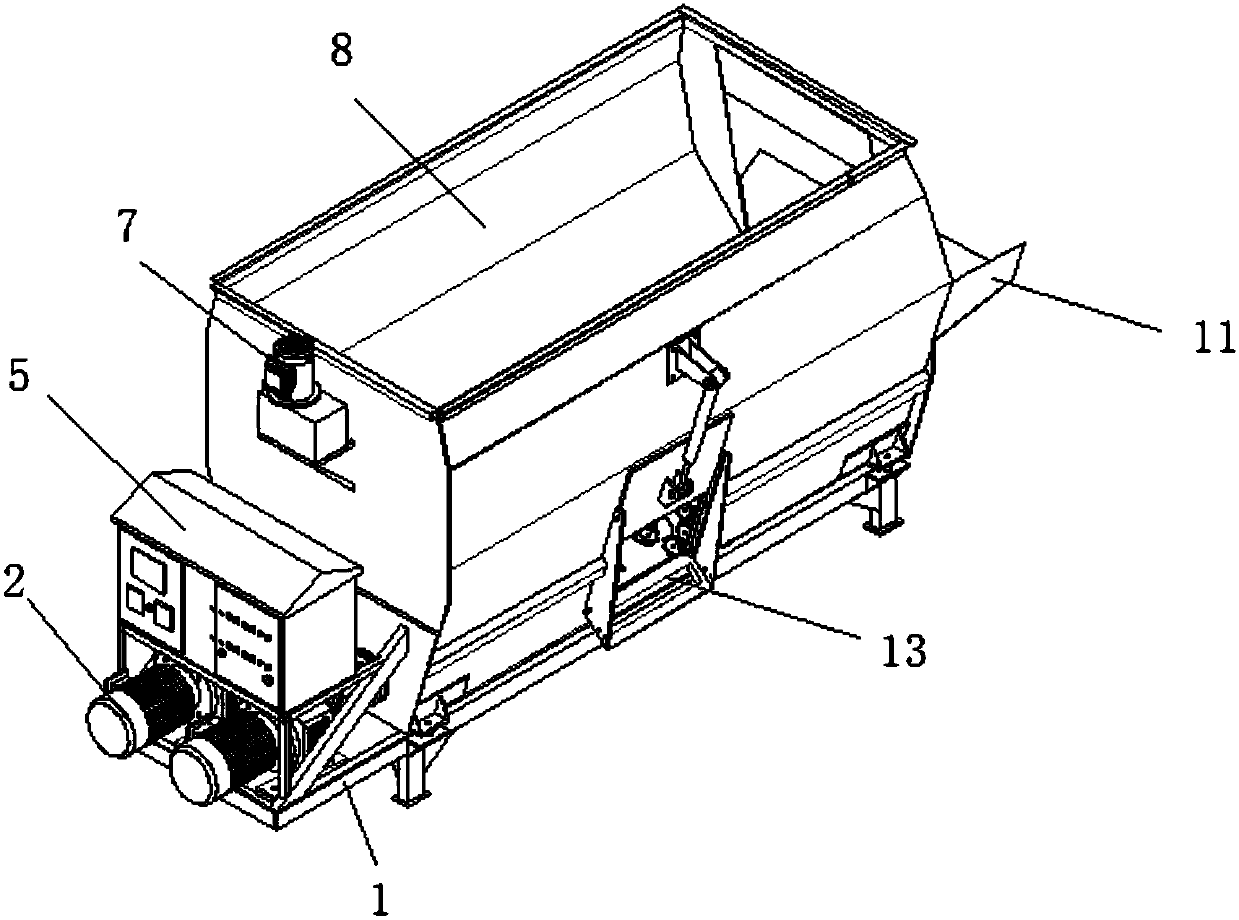

[0029] Such as figure 1 As shown, a stirring feeding machine of the present invention includes a stirring box 8, a segmented auger 10 and a driving mechanism; two parallel segmented augers 10 are horizontally arranged in the mixing box 8 and driven by the driving mechanism.

[0030] The mixing box 8 is in a horizontal cylindrical shape, and the mixing box 8 is provided with a feed inlet 11 on the side of the mixing box 8 .

[0031] The driving mechanism includes a stirring motor 2, a gearbox 3 and a coupling 4. The stirring motor 2 is fixedly connected to the outside of the stirring box 8 and is sequentially connected through the gearbox 3 and the coupling 4 to drive the segmented auger 10.

[0032] Stirring motor 2 is fixed by motor frame 1.

[0033] The segmented auger 10 is divided into a forward stirring section 101 and a reverse stirring section 104, and the forward stirring section 101 and the reverse stirring section 104 respectively have a number of spirally distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com