Novel pulp preparation device for producing rice protein (peptide) powder

A new type of rice protein technology, applied in mixers with rotating stirring devices, application, transportation and packaging, etc., can solve problems affecting product quality, simple structure, single function, etc., to save labor costs and improve production efficiency , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

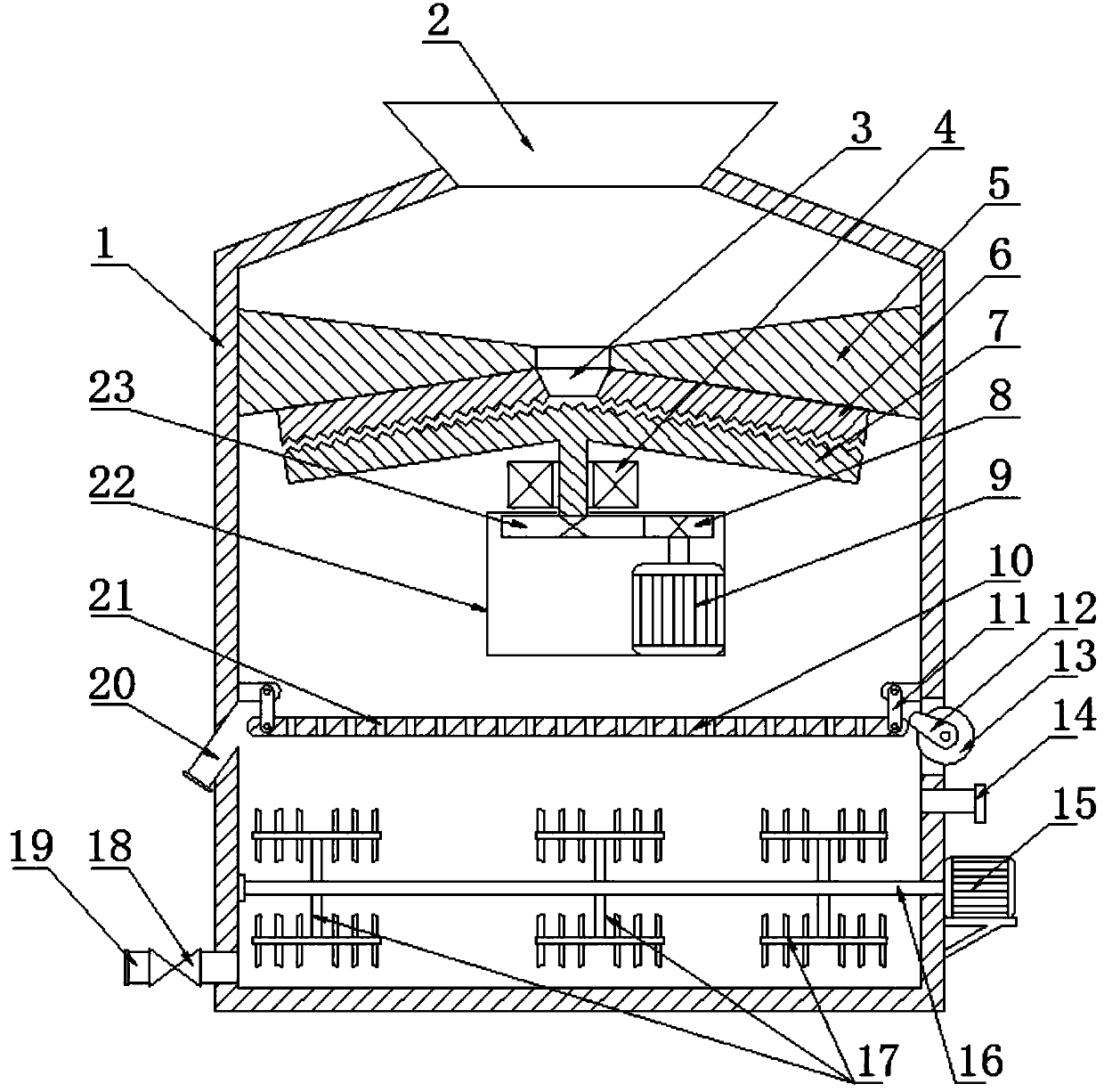

[0009] Embodiment 1, as figure 1 As shown, a new type of pulping device for producing rice protein (peptide) powder, including body 1, feeding bin 2, feeding port 3, support bearing 4, material guide block 5, fixed grinding disc 6, movable Milling disc 7, driving gear 8, first motor 9, sieve plate 10, connecting rod 11, cam 12, second motor 13, water inlet pipe 14, third motor 15, rotating shaft 16, stirring paddle 17, solenoid valve 18, The first discharge pipe 19, the second discharge pipe 20; wherein: the top of the body 1 is provided with a feed bin 2, and both sides of the body 1 are provided with guide blocks 5, the guide block 5 is connected with the body 1, and the two guide blocks A feed port 3 is provided between the material blocks 5, a fixed milling disc 6 is provided on the lower surface of the material guide block 5, and a movable milling disc 7 is provided at the lower end of the fixed milling disc 6, and the movable milling disc 7 is movable with the supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com