Wound dressing based on gas oxygen supply and production method of wound dressing

A wound dressing and gas supply technology, applied in the field of medical hygiene products, can solve problems such as poor healing effect, and achieve the effects of accelerating the wound healing process, reducing pain, and reducing pain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

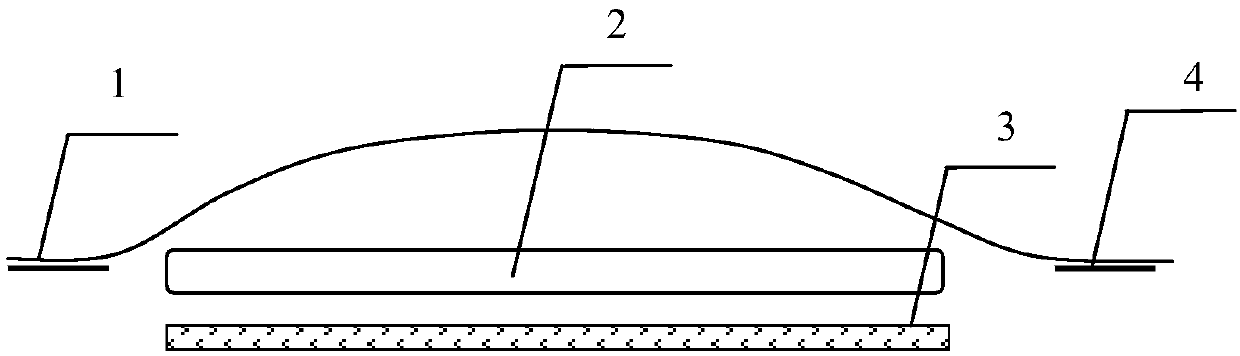

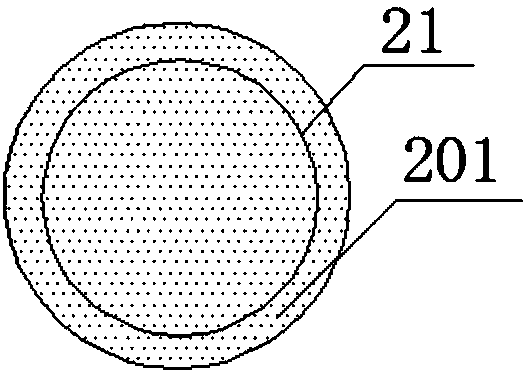

[0024] Such as figure 1 As shown, a wound dressing based on gas oxygen supply is composed of a waterproof membrane 1, a gas storage container 2, an absorbent pad 3 and a protective membrane from top to bottom. The gas storage container 2 contains high-concentration oxygen at a certain pressure, which can provide an oxygen-enriched environment for the wound, which is beneficial to accelerate the wound healing process; relieve pain of the patient; and is beneficial to repair scars and make the wound beautiful. The container wall of gas storage container 2 is provided with aperture 21, as figure 2 As shown, the small hole 21 is covered with a water-dissolvable material 201, and the water-dissolvable material can be gelatin, PVA, CMC, HEC, HPMC, starch film, etc., or any combination thereof. Materials that can dissolve in water dissolve when contacting wound secretions, so that the oxygen in the gas storage container 2 is released to the surface of the wound, providing an oxygen...

Embodiment 2

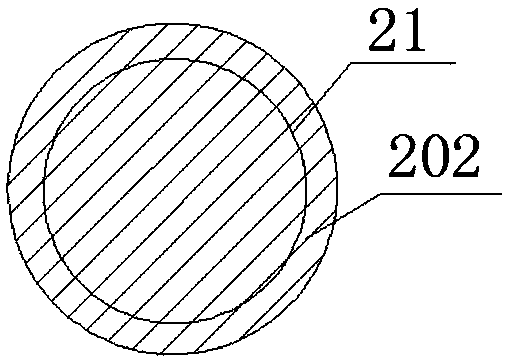

[0031] Such as figure 1 with 3 As shown, the difference between this embodiment and Embodiment 1 is that a small hole 21 is arranged on the container wall of the gas storage container 2, and the small hole 21 is covered with a gas-permeable film 202, and oxygen is slowly released through the gas-permeable film 202, which can Continuous oxygen supply to the wound.

[0032] The preparation method of the dressing comprises the following steps: 1) pre-processing the small hole 21 on the container wall of the gas storage container 2, and covering it with a gas-permeable film 202; the waterproof film 1 and the protective film of the dressing are well sealed.

Embodiment 3

[0034] Such as figure 1 with 4 As shown, the difference between this embodiment and Embodiment 1 is that the container wall of the gas storage container 2 is provided with a small hole 21, and the small hole 21 is covered with a material 201 that can dissolve in water and a gas-permeable film 202. The water-soluble material 201 covers the outside of the gas-permeable membrane 202 . In use, the water-soluble material 201 dissolves when it contacts wound secretions, and oxygen is released to the wound through the gas-permeable membrane 202 .

[0035] The method for preparing the gas storage container 2 comprises the following steps:

[0036] A small hole 21 is pre-processed on the container wall of the gas storage container 2, and covered with a gas-permeable film 202, and the outer surface of the gas-permeable film 202 is covered with a material 201 that can dissolve in water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com