A circulating flame rapid disinfection device for medical equipment

A technology for disinfection devices and medical devices, which is applied in the direction of disinfection, water supply devices, sanitary equipment for toilets, etc. It can solve the problems of reduced disinfection efficiency of medical devices, unclean cleaning, and burns to medical staff, so as to shorten the cycle of disinfection treatment, The effect of reducing the number of clips and ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

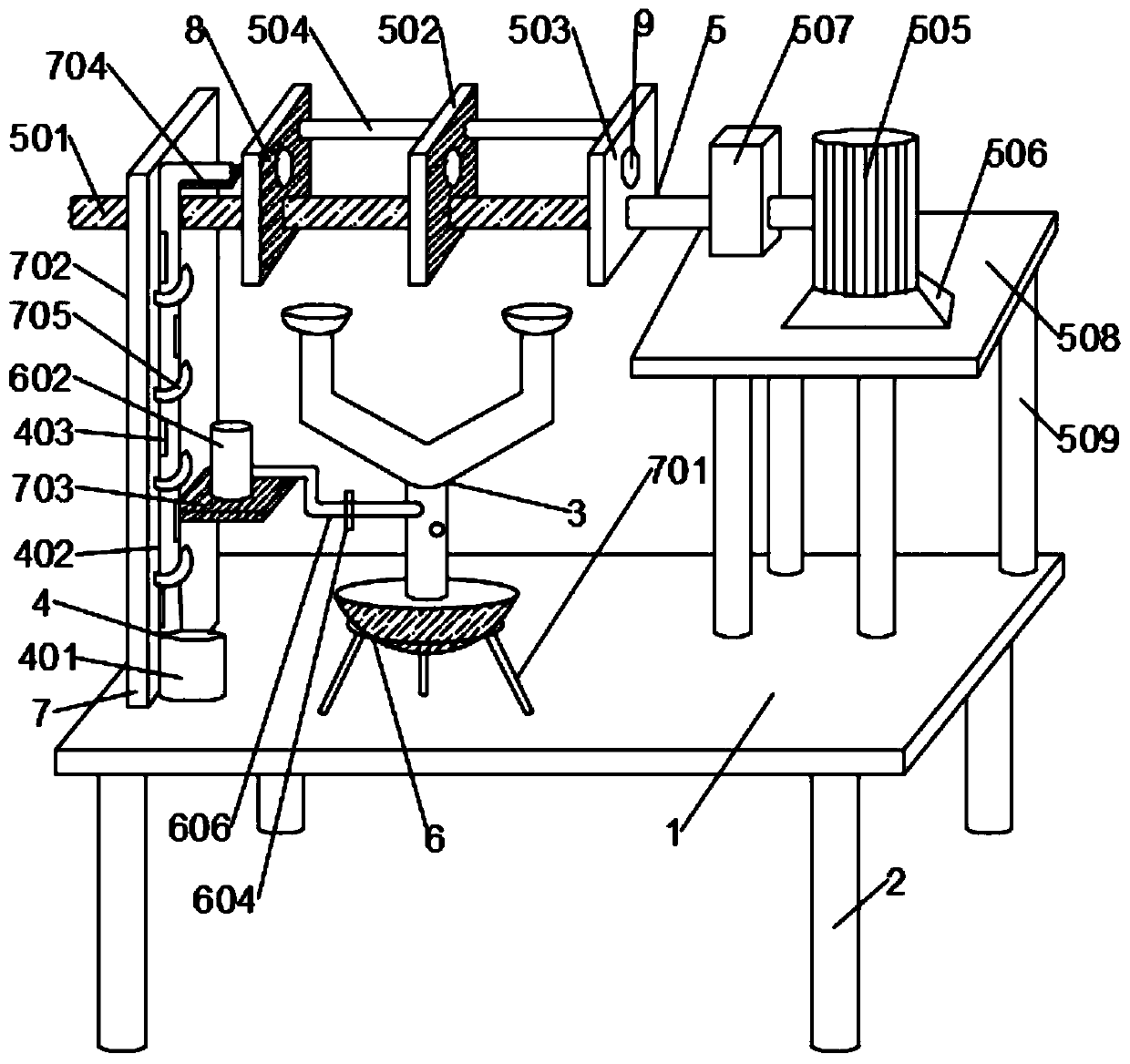

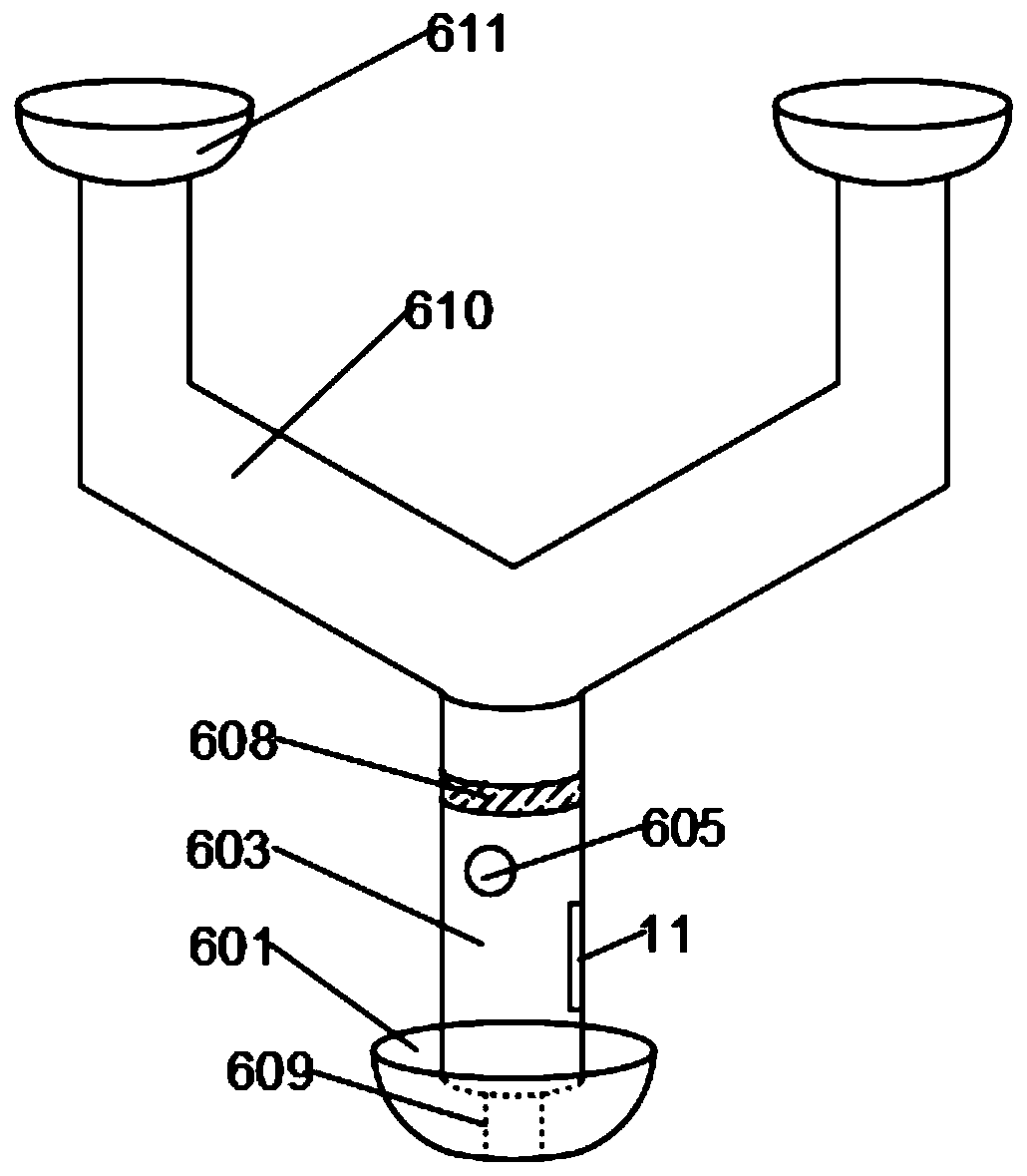

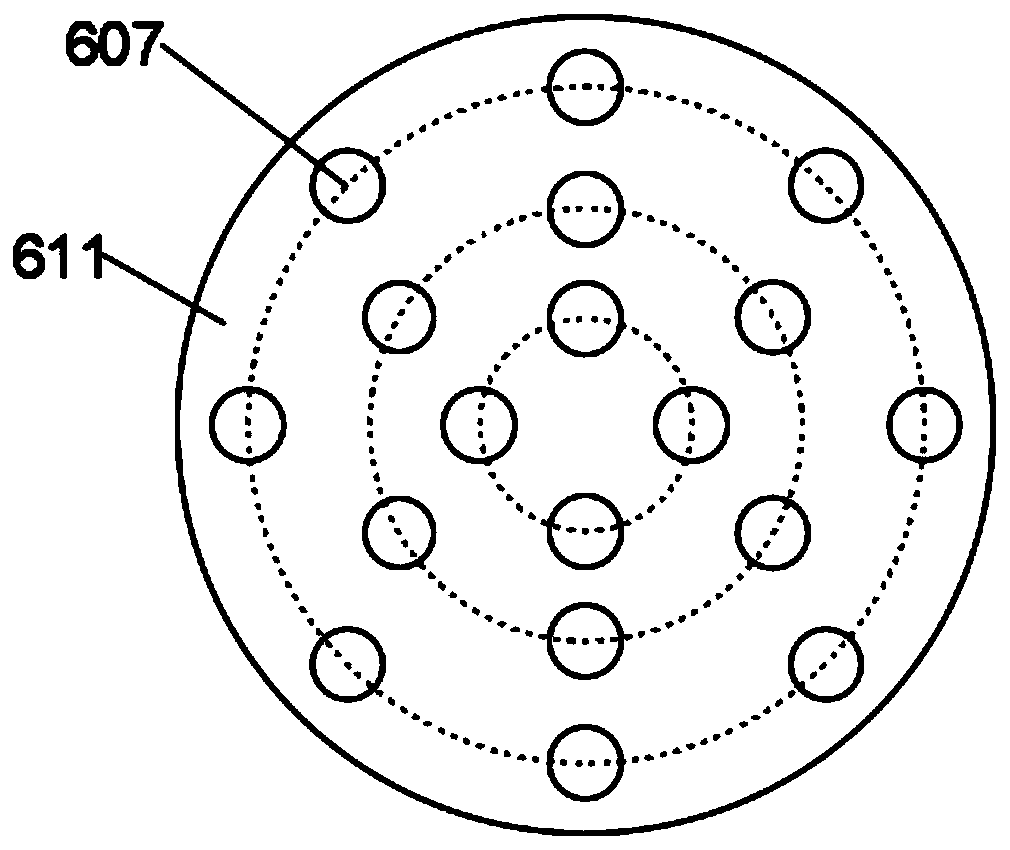

[0028] Such as figure 1 , figure 2 and image 3As shown, the present invention discloses a circulating flame rapid disinfection device for medical instruments, including a workbench 1, pillars 2 are arranged at the four corners below the workbench 1, and flame sterilizers are arranged above the workbench 1. Device 3, cooling device 4 and adjustable clamping device 5, the adjustable clamping device 5 is used for clamping and fixing the medical instrument, in case in the disinfection process, need to manually control the medical equipment, affect the disinfection operation, and then pass The flame sterilizer 3 performs flame disinfection on it, and the cooling device 4 is used for cooling and cooling the medical instruments sterilized by the flame sterilizer, so that the surface temperature of the sterilized medical instruments can be quickly reduced, so that the medical instruments are It can be used within a short period of time after disinfection, thereby greatly shortenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com