Three-layer composite flexible escape passageway

An escape route, composite flexible technology, applied in the direction of layered products, life-saving equipment, rubber layered products, etc., can solve the problems of large space occupation, complex structure principle, increased use limitations, etc., and achieve good fire resistance and flame retardancy, The process is simple and effective, and the effect of improving the adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

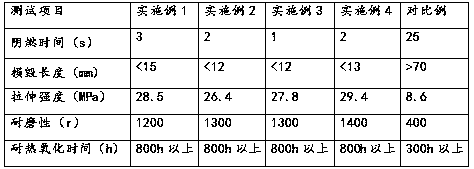

Examples

Embodiment 1

[0026]A three-layer composite flexible escape channel, the flexible escape channel includes three layers, the outer layer is a flame-retardant layer, the middle layer is a heat-insulating layer, and the inner layer is a breathable layer; wherein the material of the flame-retardant layer includes the following raw materials by weight: nano 30 parts of carbon fiber, 25 parts of nano ceramic fiber, 15 parts of flame retardant, 8 parts of filler, 0.8 part of antioxidant, 7 parts of graphene, 6 parts of nylon, 3 parts of toughening agent, 30 parts of polypropylene;

[0027] The heat insulation layer material includes the following raw materials in parts by weight: 30 parts of carbon nanofibers, modified SiO 2 12 parts of airgel, 10 parts of graphene, 3 parts of expanded perlite, 8 parts of flame retardant, 3 parts of antioxidant, 6 parts of nylon, 3 parts of toughening agent, 30 parts of polyethylene;

[0028] The breathable layer includes the following raw materials in parts by we...

Embodiment 2

[0031] A three-layer composite flexible escape channel, the flexible escape channel includes three layers, the outer layer is a flame-retardant layer, the middle layer is a heat-insulating layer, and the inner layer is a breathable layer; wherein the material of the flame-retardant layer includes the following raw materials by weight: nano 35 parts of carbon fiber, 30 parts of nano ceramic fiber, 20 parts of flame retardant, 9 parts of filler, 1.2 parts of antioxidant, 10 parts of graphene, 8 parts of nylon, 4 parts of toughening agent, 32 parts of polypropylene;

[0032] The insulation layer material includes the following raw materials in parts by weight: 40 parts of carbon nanofibers, modified SiO 2 18 parts of airgel, 12 parts of graphene, 3 parts of expanded perlite, 9 parts of flame retardant, 3 parts of antioxidant, 6 parts of nylon, 3 parts of toughening agent, 35 parts of polyethylene;

[0033] The breathable layer includes the following raw materials in parts by weig...

Embodiment 3

[0036] A three-layer composite flexible escape channel, the flexible escape channel includes three layers, the outer layer is a flame-retardant layer, the middle layer is a heat-insulating layer, and the inner layer is a breathable layer; wherein the material of the flame-retardant layer includes the following raw materials by weight: nano 40 parts of carbon fiber, 35 parts of nano-ceramic fiber, 24 parts of flame retardant, 9 parts of filler, 0.8 part of antioxidant, 7 parts of graphene, 6 parts of nylon, 3 parts of toughening agent, and 38 parts of polypropylene;

[0037] The insulation layer material includes the following raw materials in parts by weight: 50 parts of carbon nanofibers, modified SiO 2 20 parts of airgel, 14 parts of graphene, 3 parts of expanded perlite, 8 parts of flame retardant, 3 parts of antioxidant, 6 parts of nylon, 3 parts of toughening agent, and 30 parts of polyethylene;

[0038] The breathable layer includes the following raw materials in parts b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com