A device for efficient separation and automatic circulation of powder catalysts in the process of catalytic oxidation treatment of sewage

A technology of catalytic oxidation and automatic circulation, applied in the field of water pollution control, can solve the problems of restricting wide application, loss of catalyst, complicated operating procedures, etc., and achieve the effect of strengthening, efficient separation and operation, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

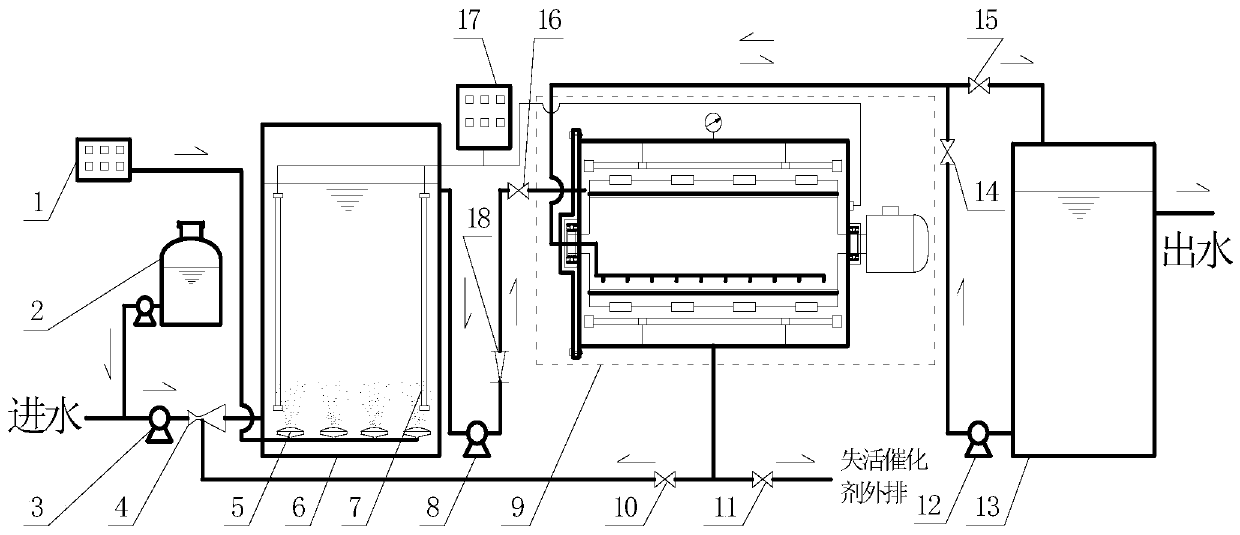

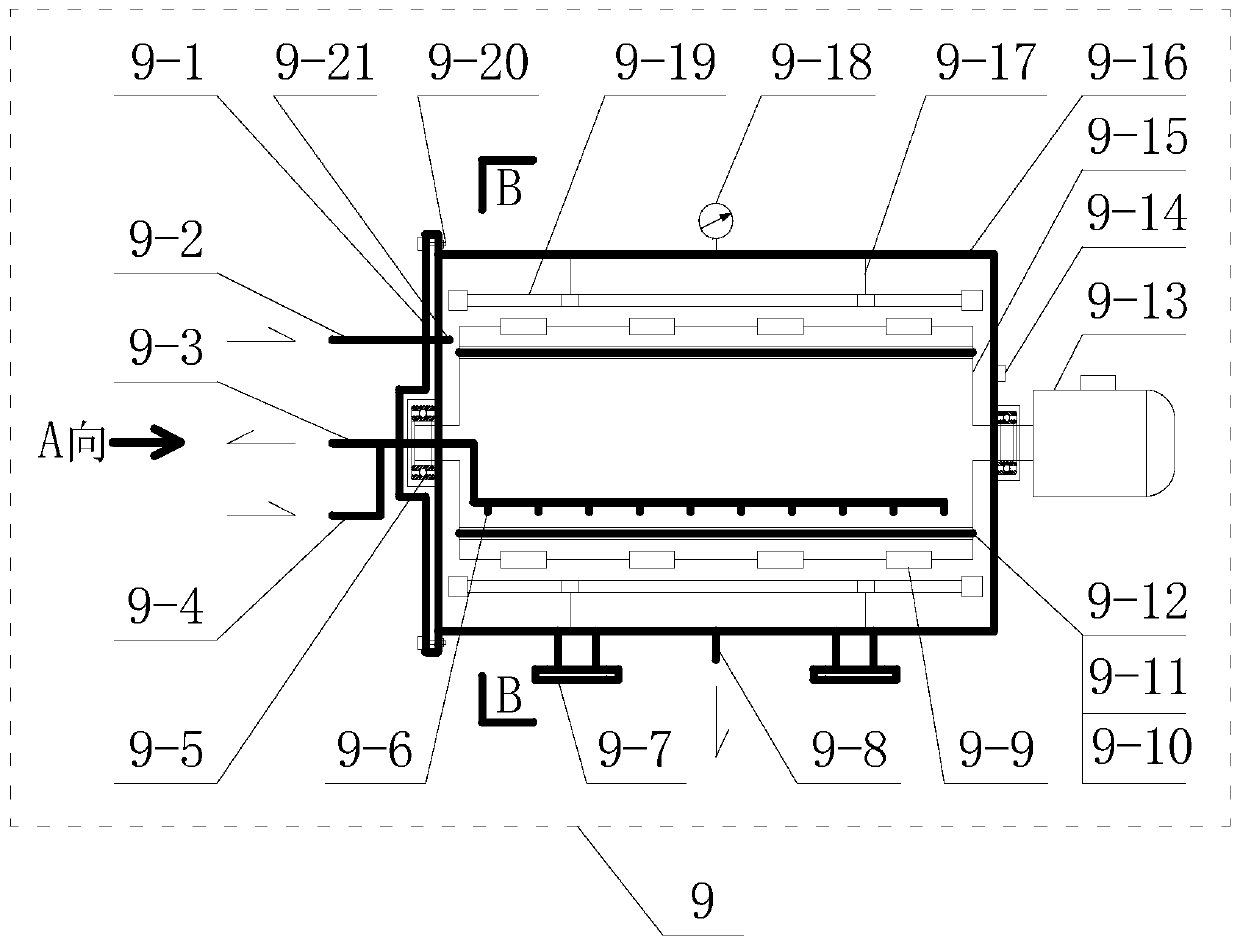

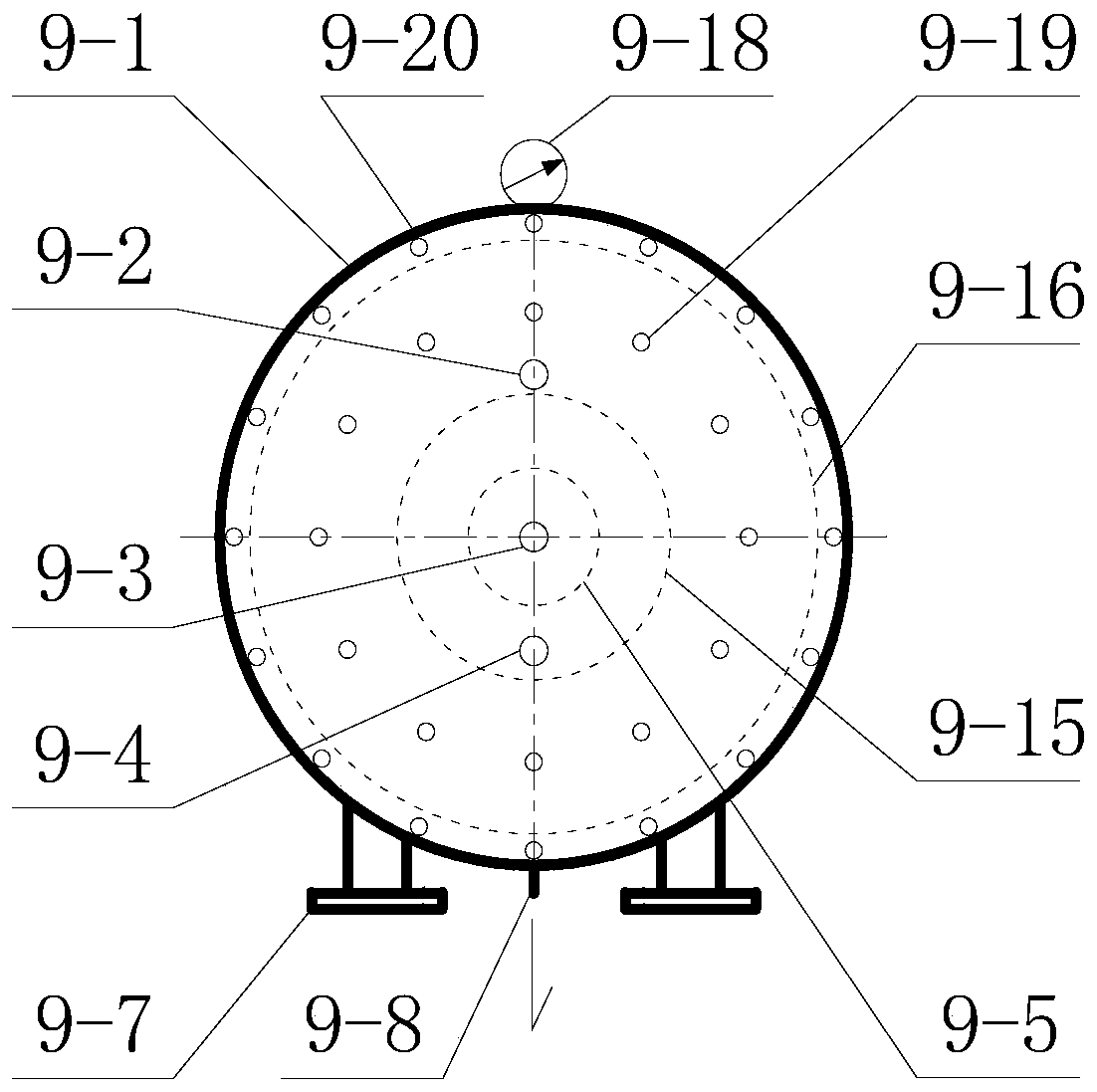

[0033] The functions and advantages of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] combine figure 1 In the process of efficient separation and automatic circulation of the powder catalyst of the present invention, the following four steps are included: water inflow mixing, catalytic oxidation reaction, catalyst separation and automatic circulation, clear water storage and pulse backwashing, wherein:

[0035] 1) The water inlet mixing part is composed of a strong oxidant dosing device 2, a lift pump 3 and a water injector 4. The oxidant stored in the strong oxidant dosing device 2 is added to the suction pipeline of the lift pump 3, and the blades of the lift pump 3 are used to The agitation realizes the mixing of sewage and strong oxidant, and the water outlet of lift pump 3 and the recycled powder catalyst realize the complete mixing of sewage, oxidant and catalyst in water injector 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com