A fully enclosed argon protection device and protection method thereof

An argon shielded, fully enclosed technology, applied in metal processing equipment, manufacturing tools, casting melt containers, etc., can solve problems such as low flexibility of adaptation, reduce the performance change of steel materials, reduce temperature difference, reduce The effect of secondary utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

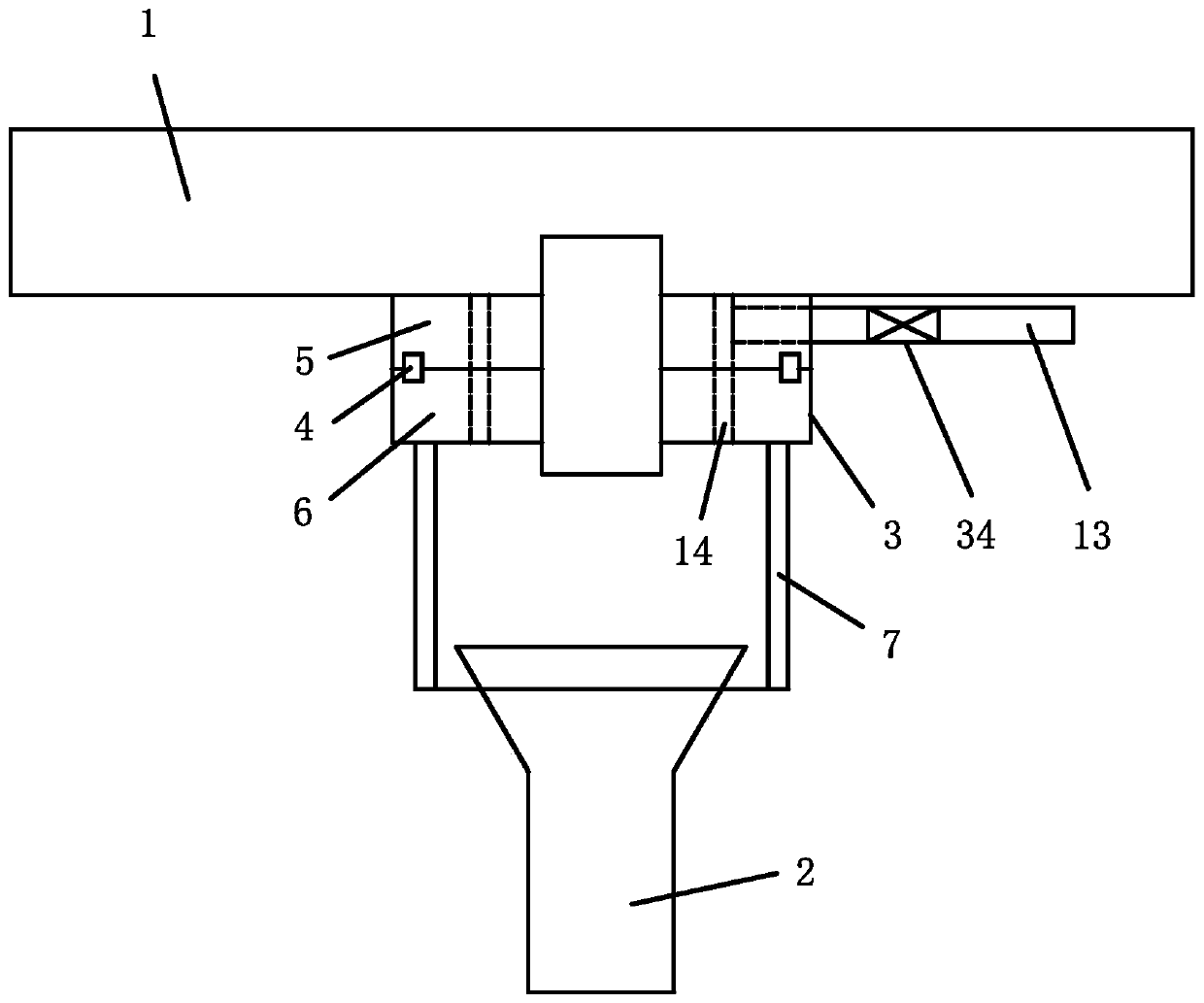

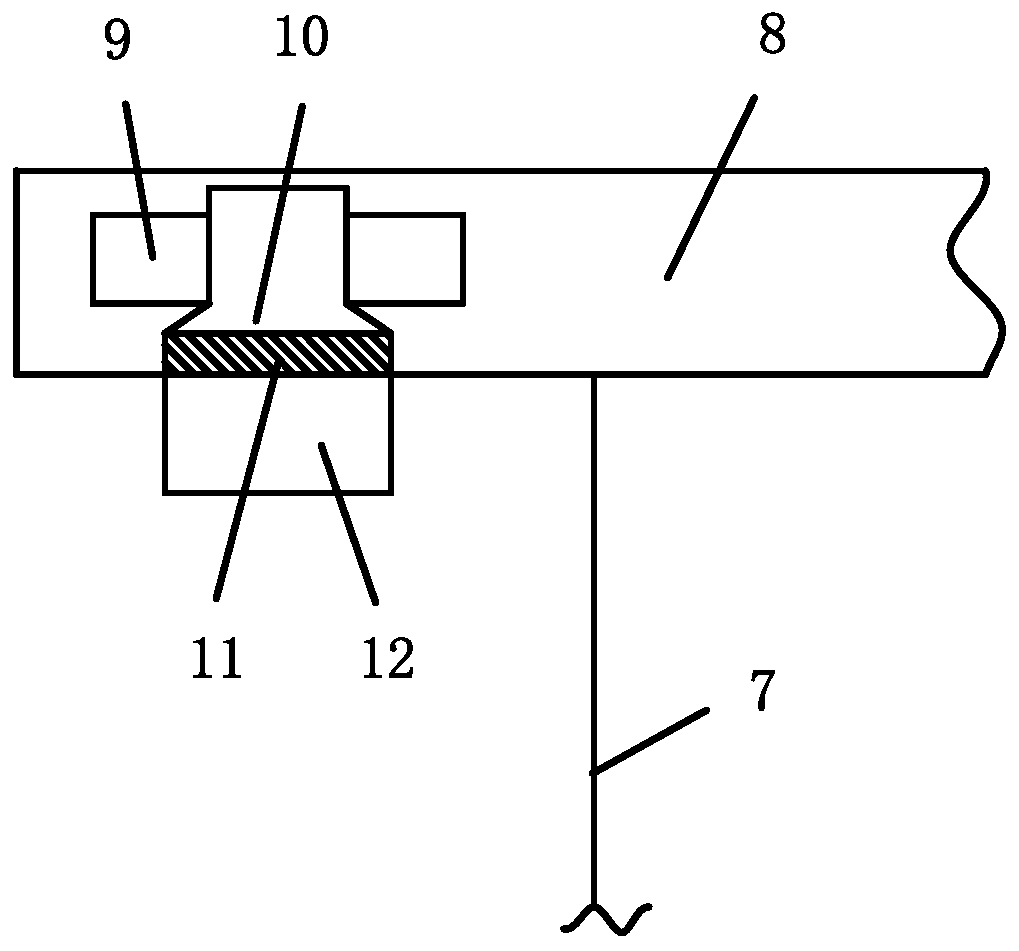

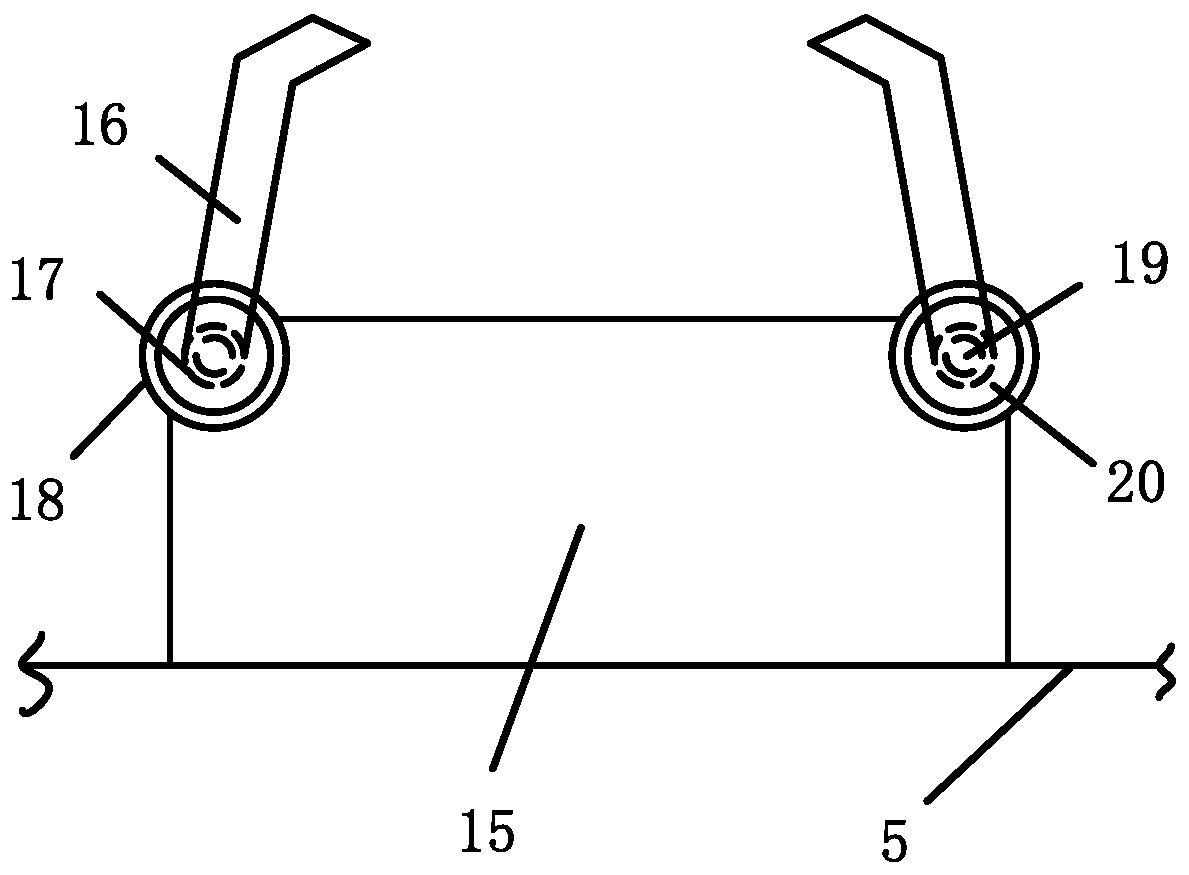

[0025] refer to Figure 1-6 , a specific embodiment of the present invention comprises a ladle 1 and a funnel brick 2, and an argon protection ring 3 is fixed below the ladle 1, and the argon protection ring 3 includes an upper ring 5 and a lower ring fixed together by screws 4 6, the bottom of the lower ring 6 is sleeved with a refractory cylinder 7, the bottom of the refractory cylinder 7 is sleeved on the outside of the funnel brick 2, and the inner ring of the lower ring 6 is provided with several vertical air injection holes 14, The argon gas pipe 13 is connected with the jet hole 14; the top of the refractory cylinder 7 is provided with an annular refractory elastic member 8, and two elastic metal rings 9 are concentrically arranged in the annular refractory elastic member 8, and there is a connection between the two elastic metal rings 9 Several tapered sleeves 10, the bottom of the annular refractory elastic member 8 is provided with a threaded sleeve 11 corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com