Drill point special for soft-hard combination plate

A technology that combines soft and hard plates and drill needles. It is used in repairing drills, drilling tool accessories, drilling/drilling equipment, etc. It can solve the problems of wrinkling, easy tearing of drilling, and failure of drilling effect to meet quality requirements. , to achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

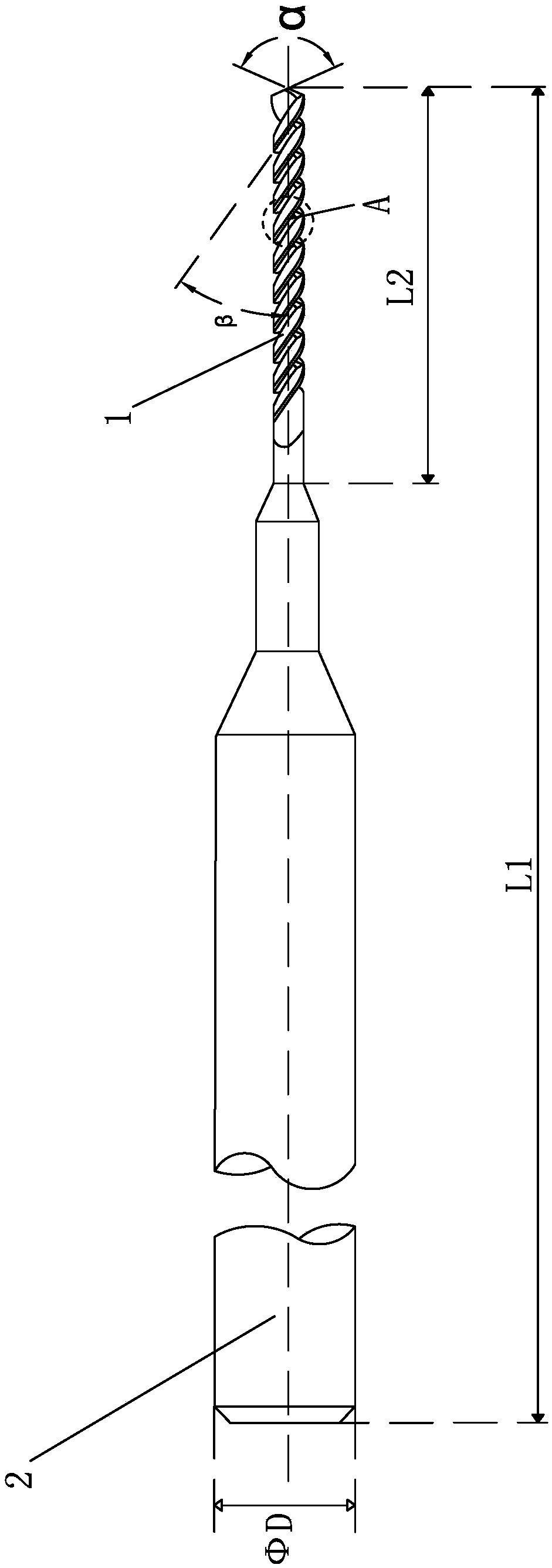

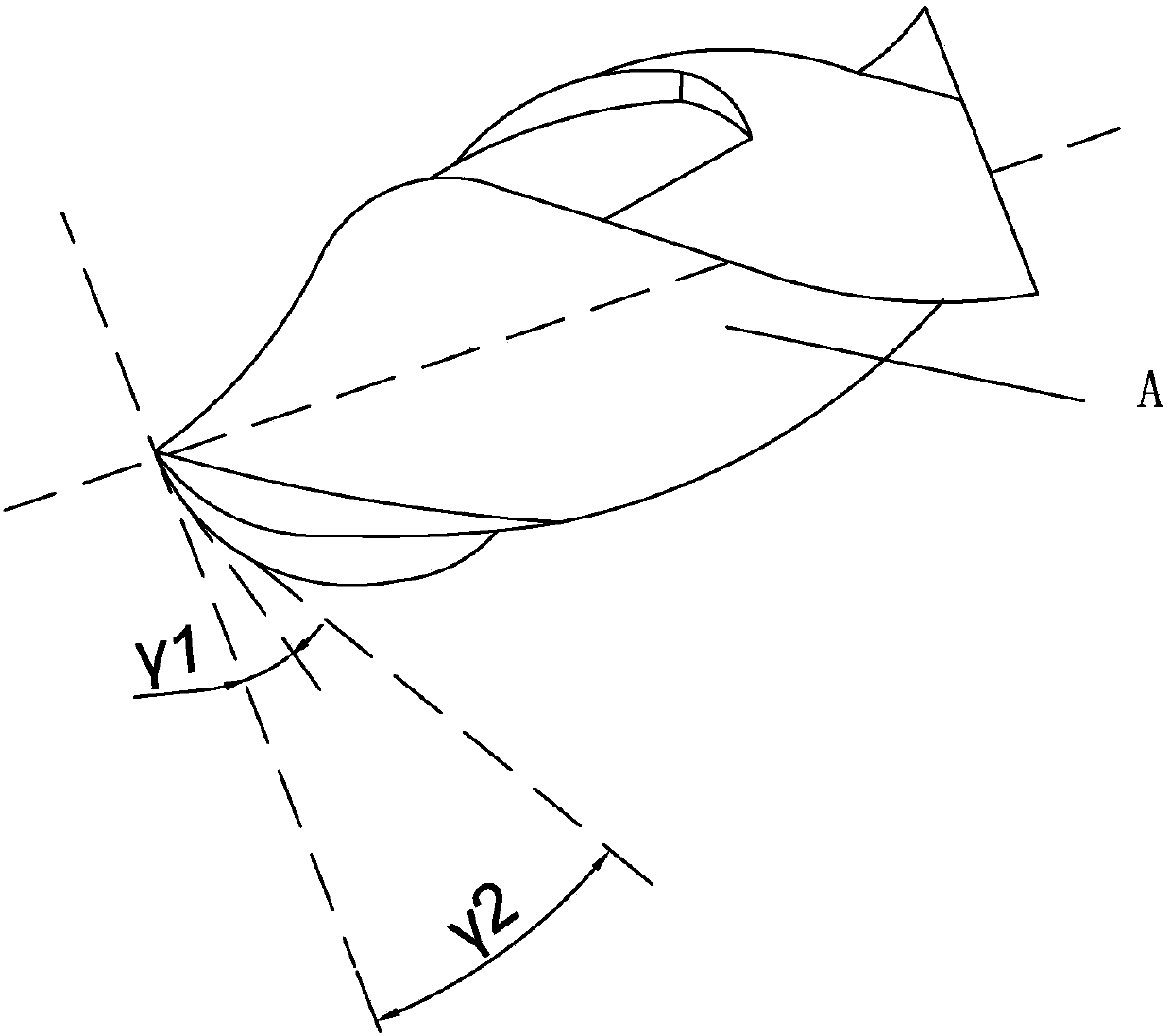

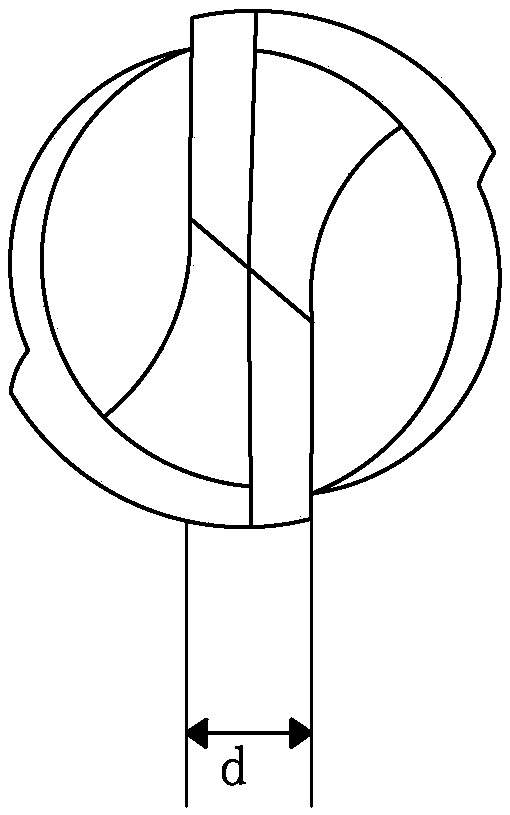

[0019] refer to figure 1 , is a better implementation. A special drill for soft-hard boards, comprising a drill 1 and a handle 2, the angle α of the drill tip of the drill 1 is 125°-135°, the diameter ΦD of the handle 2 is 3.0mm-3.2mm and the drill The drill core thickness d of the cutter 1 is 0.05 mm to 0.06 mm, the helix angle β of the drill cutter 1 is 33° to 39°, the first face angle γ1 is 12° to 18° and the second face angle γ2 is 27° to 33° °.

[0020] Further, the size of the drill point angle α will affect the discharge direction of the cuttings and the shape of the cutting chips, as well as the generation of cutting resistance burrs and so on. When the drill point angle α is large, the granular discharge is easier to discharge chips, but at the same speed, the pulling force on the soft-hard combination plate is greater, and sticking, swirling, and burrs are prone to occur. On the contrary, when the drill point angle α is small, the discharge becomes strips and is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com