Takeoff and landing method of aircraft in aircraft carrier and device thereof

A technology for landing gear and aircraft, applied in aircraft parts, ground equipment, aircraft control, etc., can solve the problems of not being able to save deck layout area, not being able to take off with heavy loads, and high structural requirements, so as to achieve low aircraft structure requirements and save hull decks panel, pilot comfort effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

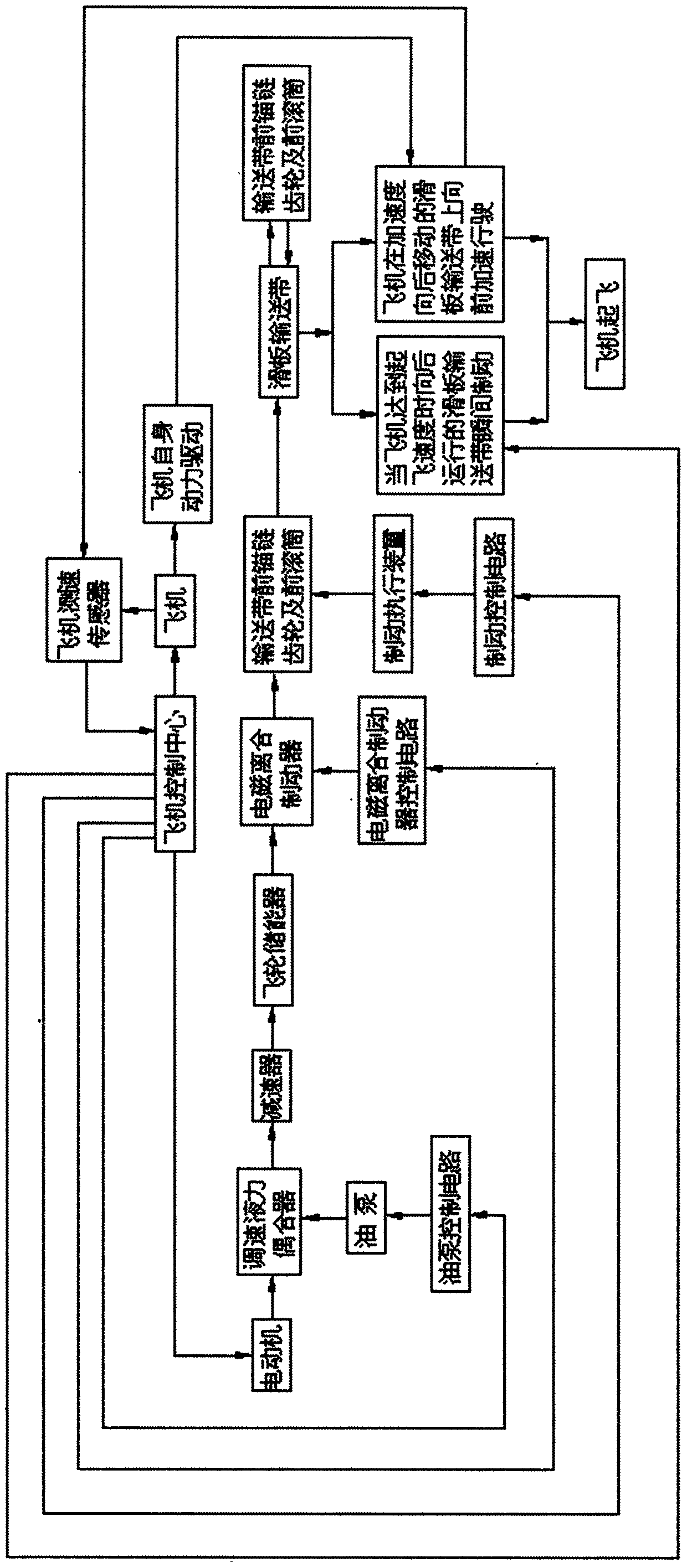

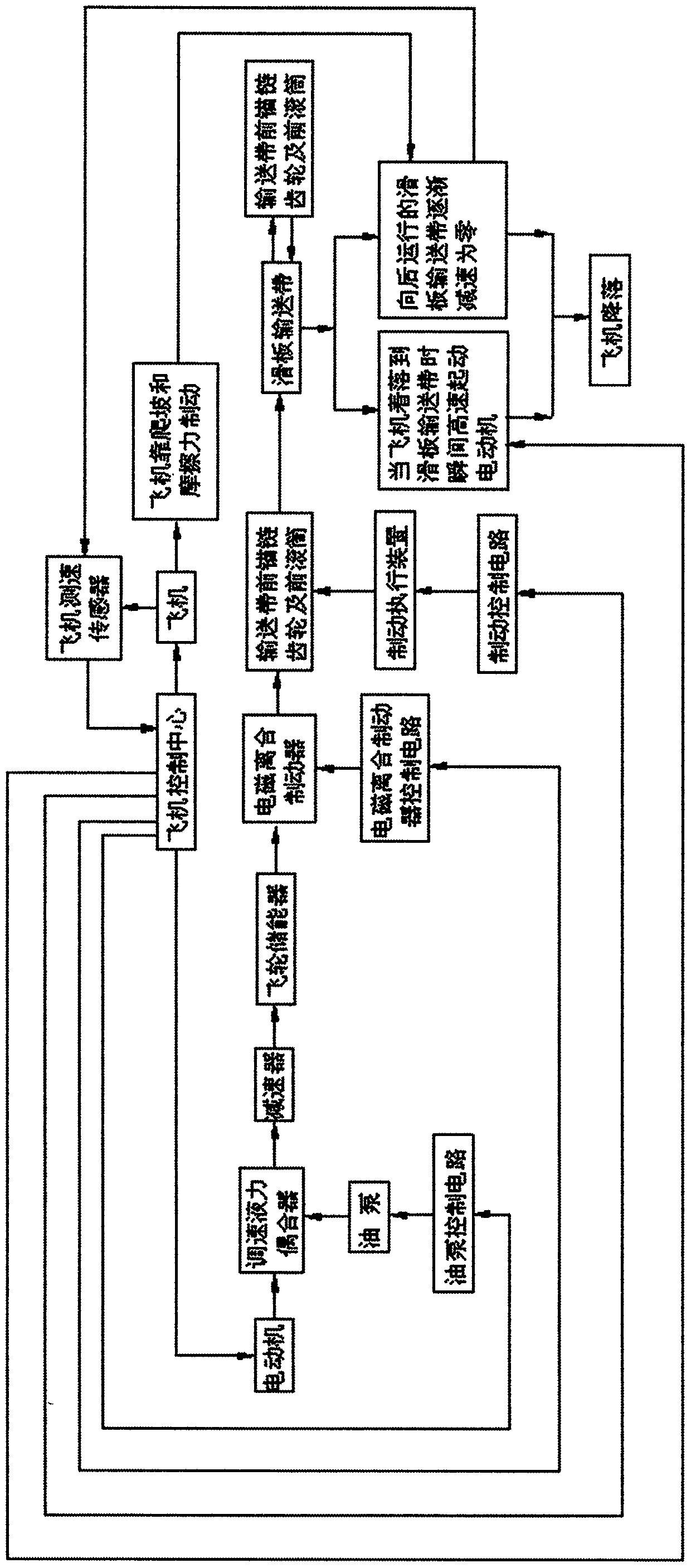

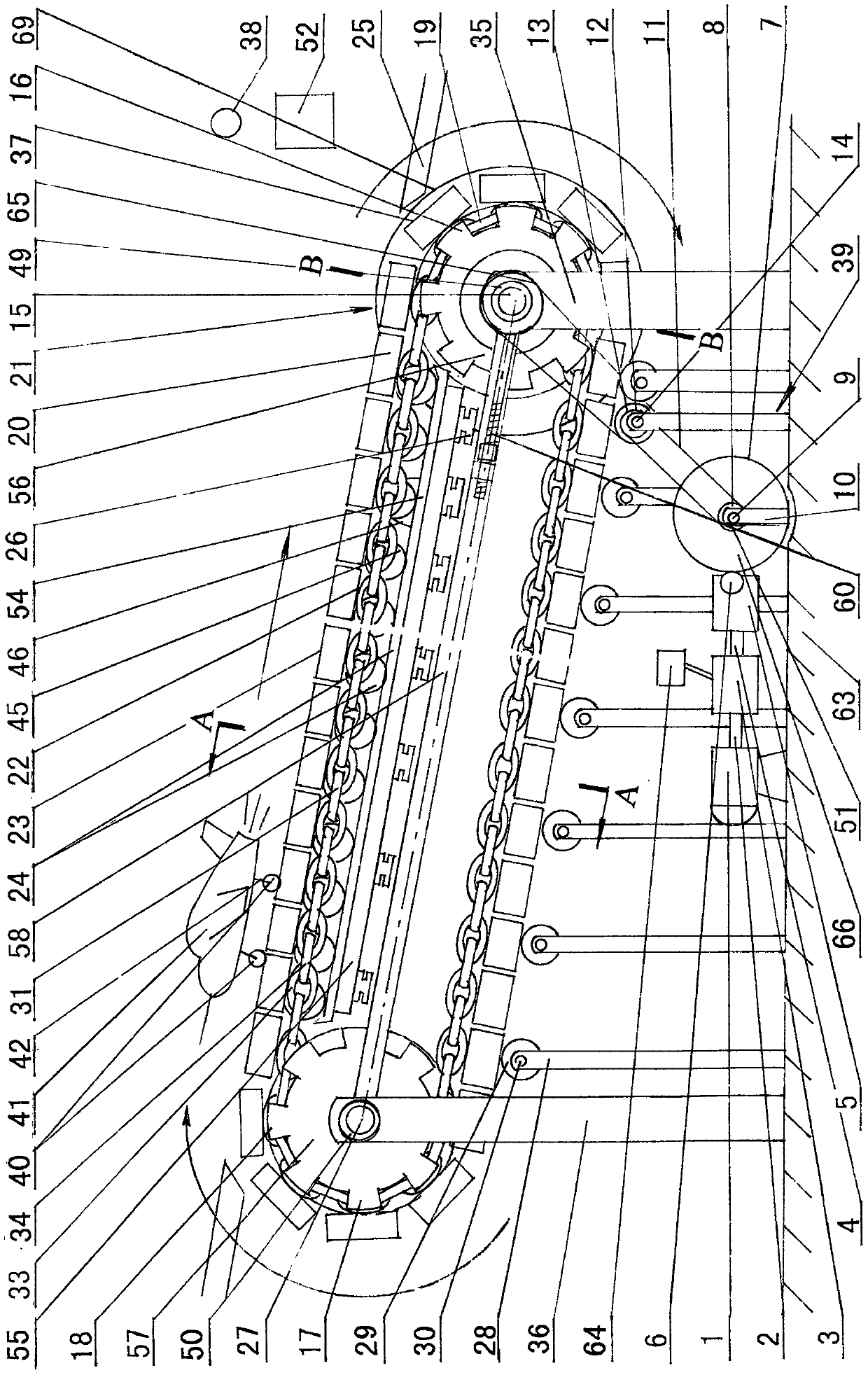

[0090] figure 1 Among them, the aircraft 41 is parked on the outer surface of the slide conveyor belt with a high front and a low slope at one end of the rear roller 56, that is, the rearmost end of the delivery runway 23. The inclination angle of the slide conveyor belt outer surface 23 is 0-30°, preferably 10°. ° left and right, aircraft 41 is ready to take off, and when aircraft control center 52 sends take-off command, aircraft 41 starts, and slides forward on the slide conveyor belt surface, promptly conveys runway 23; Control center 52; Aircraft control center 52 connects the power supply of motor 1 according to the requirement of aircraft 41 take-off, and motor 1 starts; The acceleration of the aircraft 41 on the measured slide conveyor belt 21 a2 When , the output signal instructs the oil pump 64 to control the circuit to increase the fuel supply of the oil pump 64 and increase the speed of the output shaft 4 of the speed-regulating hydraulic coupling. Its S is the set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com