Sorting and detection all-in-one machine for gutta percha points

An all-in-one machine and gutta-percha tip technology, applied in the direction of conveyors, measuring devices, conveyor objects, etc., can solve problems such as non-compliance with specifications, product outflow, and failure to represent the situation of gutta-percha tip products, so as to avoid time-consuming and labor-intensive cost, avoiding machine jams, and avoiding missed inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

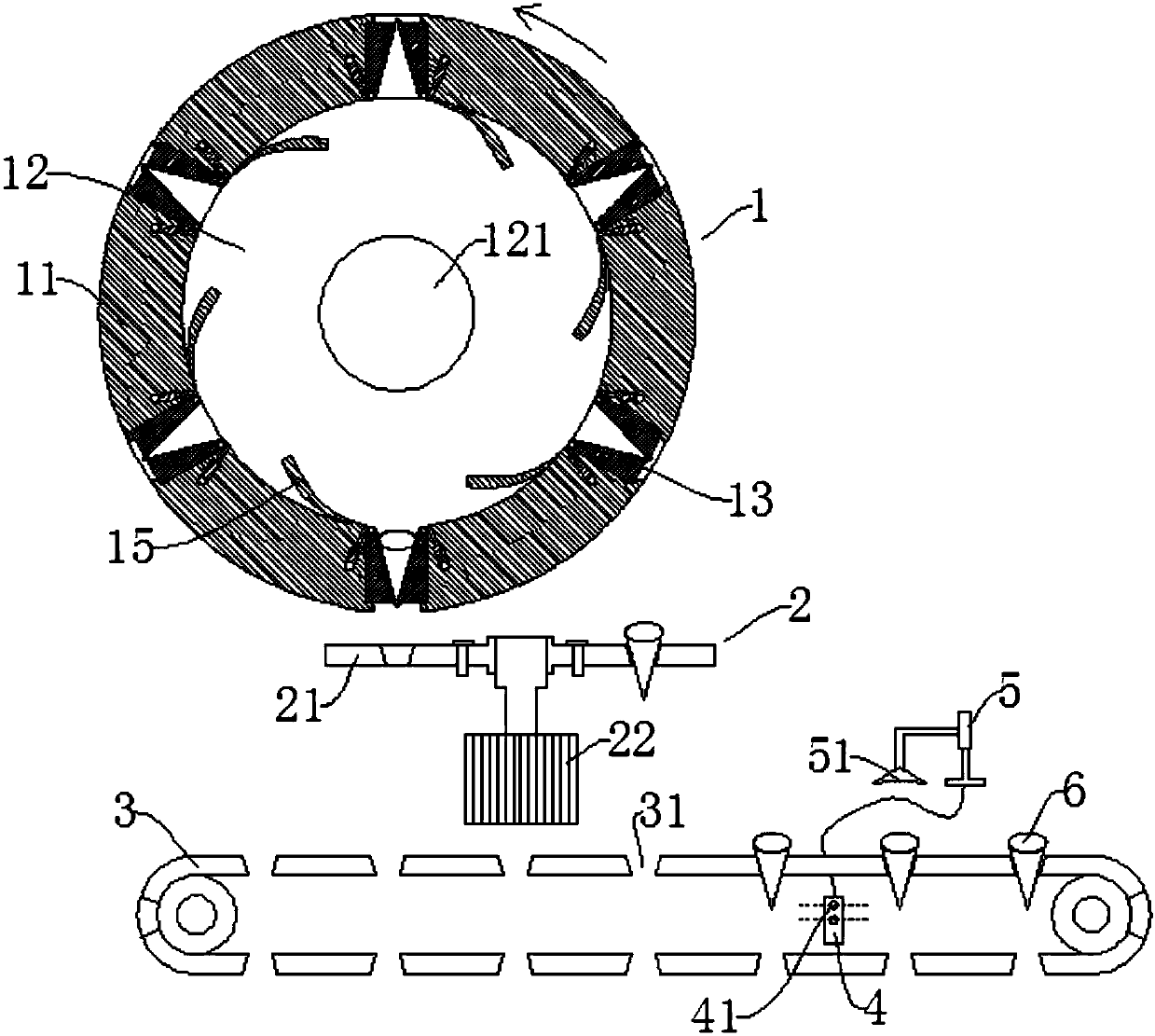

[0022] The all-in-one sorting and detecting machine for gutta-percha tip provided by the present invention is as follows: figure 1 As shown, it includes a finishing tray 1, a transfer mechanism 2, a conveyor belt 3 and a detection piece 4; the finishing tray 1 sends the gutta-percha points 6 into the clamp 21 of the transfer mechanism 2 one by one, and the transfer mechanism 2 rotates the clamp 21 The gutta-percha points 6 are sent to the clamping positions 31 on the conveyor belt 3 one by one, and the gutta-percha points 6 are driven by the conveyor belt 3 to pass through the detection parts 4 one by one for detection.

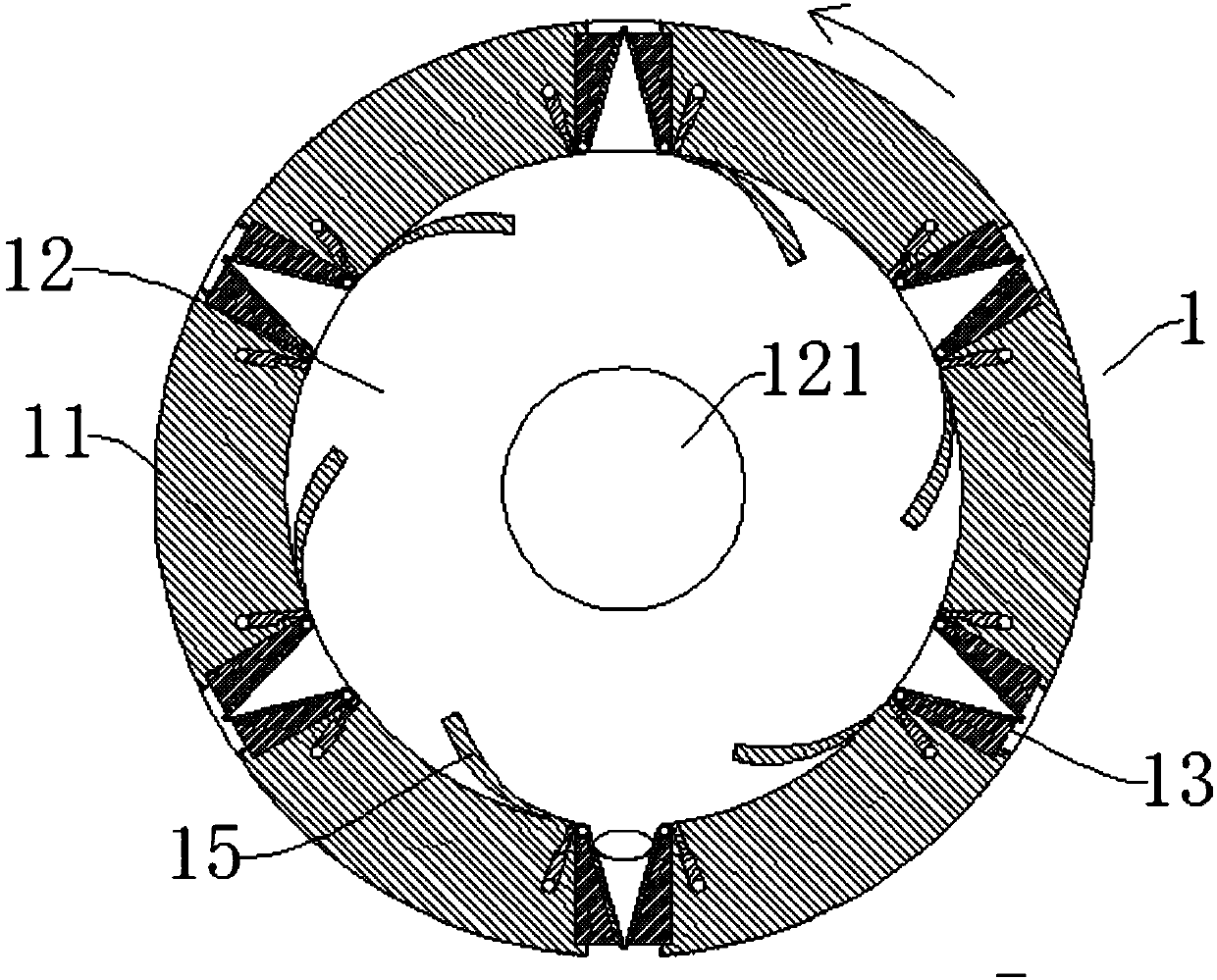

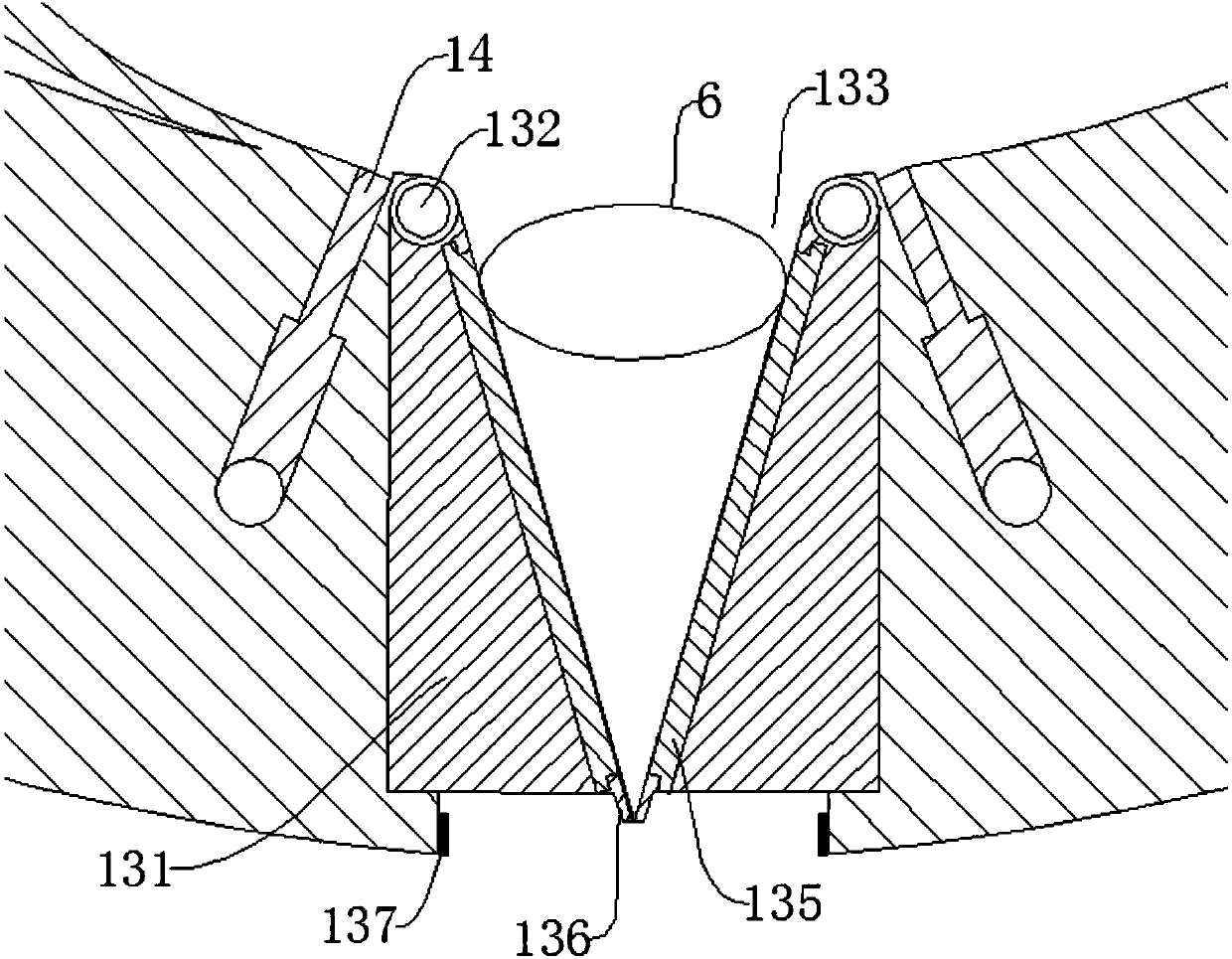

[0023] Wherein, the finishing tray 1 ( figure 2 ) includes a hollow space surrounded by an annular wall 11 and a bottom surface 12, on which several groups of switching mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com