Method for preparing carbon nanometer tubes through waste plastic catalytic pyrolysis by two-section process

A technology of carbon nanotubes and waste plastics, applied in the field of carbon nanotubes, can solve the problems of strict process requirements and complicated operation, and achieve the effect of simple operation and convenient mechanical separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

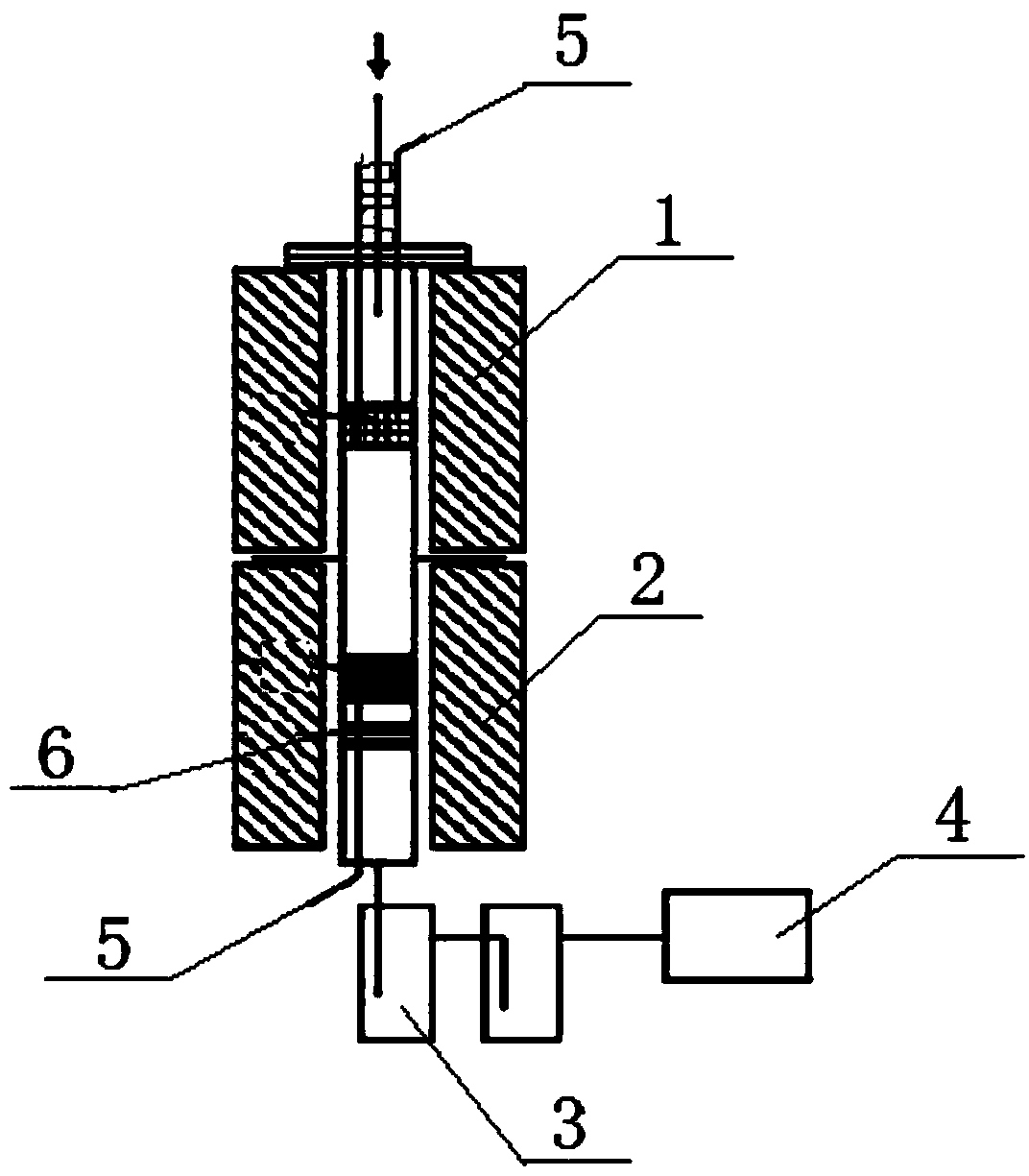

Method used

Image

Examples

Embodiment 1

[0040] Take 4 grams of waste plastic (the material is PE) and wash it with ethanol and water for several times, then air-dry it naturally, and then crush it with a pulverizer to obtain a plastic solid with a particle size of less than 1cm; vacuumize the reaction furnace, and then pass the plastic solid through a screw-feeding way into the pyrolysis furnace, while the loading of 1 gram in the catalytic reaction furnace is a 4% iron-based catalyst (the carrier is SiO 2 , iron oxide is iron oxide), and at the same time turn on the thermocouples in the pyrolysis furnace and the catalytic reaction furnace to heat them respectively, and control the reaction temperature of the pyrolysis furnace to be about 350°C, so that the plastic solid slowly generates pyrolysis gas, Control the reaction temperature of the catalytic reactor to about 500°C, and react for about 3 hours; the pyrolysis gas is catalyzed in the catalytic reactor to obtain carbon nanotubes and hydrogen, wherein the carbon...

Embodiment 2

[0043] Take 4 grams of waste plastic (the material is PP) and wash it with ethanol and water for several times, then air-dry it naturally, and then crush it with a pulverizer to obtain a plastic solid with a particle size of less than 1cm; vacuumize the reaction furnace, and then pass the plastic solid through a screw-feeding way into the pyrolysis furnace, while loading 1 gram of loading in the catalytic reaction furnace is a 6% iron-based catalyst (the carrier is SiO 2, the iron oxide is ferroferric oxide), and at the same time turn on the thermocouples in the pyrolysis furnace and the catalytic reaction furnace to heat them respectively, and control the reaction temperature of the pyrolysis furnace to be about 420°C, so that the plastic solids are slowly generated and pyrolyzed Gas, control the reaction temperature of the catalytic reaction furnace to about 650°C, and react for about 3 hours. The pyrolysis furnace and the catalytic reaction furnace are heated at the same tim...

Embodiment 3

[0046] Take 6 grams of waste plastic (made of PPS) with ethanol and water for several times, then air-dry naturally, and then use a pulverizer to pulverize to obtain plastic solids with a particle size of less than 1cm; vacuumize the reaction furnace, and then pass the plastic solids through a screw-feeding way into the pyrolysis furnace, while the loading of 1 gram in the catalytic reaction furnace is 4% iron-based catalyst (carrier is Al 2 o 3 , the iron oxide is ferroferric oxide), and at the same time turn on the thermocouples in the pyrolysis furnace and the catalytic reaction furnace to heat them respectively, and control the reaction temperature of the pyrolysis furnace to be about 500°C, so that the plastic solids are slowly generated and pyrolyzed Gas, control the reaction temperature of the catalytic reactor to about 700°C, and react for about 2 hours. The pyrolysis gas is catalyzed in the catalytic reactor to obtain carbon nanotubes and hydrogen. Among them, the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com