Dustproof, low-emission and low-odor thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, low emission technology, applied in the field of thermoplastic elastomers, can solve the problem of not having dust-proof thermoplastic elastomers at the same time, achieve broad market prospects and application value, excellent high temperature compression resistance, good low temperature resistance and The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

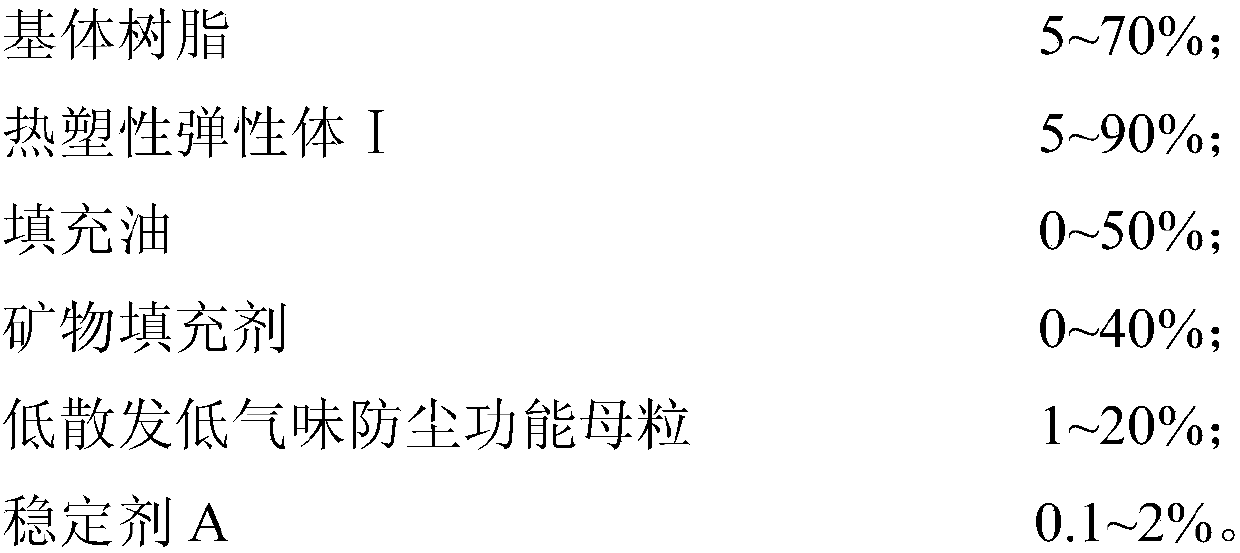

[0050] Use the following weights of ingredients:

[0051]

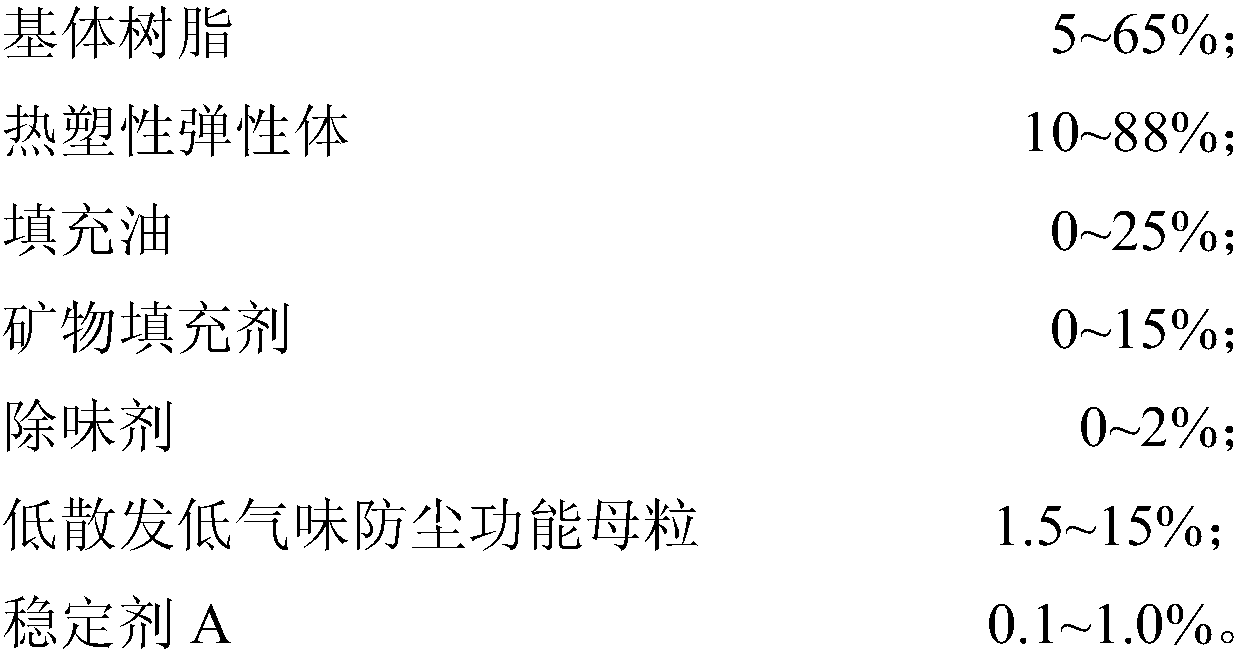

[0052] In terms of weight percentage, the formula of the self-made low-emission, low-odor and dust-proof functional masterbatch in this embodiment is as follows:

[0053]

[0054] The preparation process of the low-emission, low-odor and dust-proof functional masterbatch is as follows: mixing thermoplastic elastomer and resin, adding antistatic agent, deodorant, and stabilizer during the stirring process, and sending it into the double-stage screw after mixing evenly Extrusion and granulation in the granulation unit. The two-stage screw granulation unit is composed of a single-screw extruder and a twin-screw extruder. 200°C; the speed of the twin-screw main engine is 600 rpm, and the temperature of each section of the screw is 160°C-200°C; double vacuum suction is used during the granulation process, and the vacuum pressure is kept at 0.08MPA. A 4-hour ventilation cycle was carried out in a blast oven to finall...

Embodiment 2~5

[0062] Except for the different formulations of self-made low-emission, low-odor and dust-proof functional masterbatches, the types of other raw materials are unchanged, and the preparation process is the same as in Example 1. The specific low-emission, low-odor and dust-proof functional masterbatch formulations are shown in Table 2 below:

[0063] Table 2

[0064]

Embodiment 6

[0073] Except that the raw materials of the following weights are used, and the temperature of each screw of the twin-screw extruder is set at 240°C, other operations for the preparation of dust-proof, low-emission and low-odor thermoplastic elastomers are the same as in Example 1, and dust-proof, low-emission and low-odor thermoplastic elastomers are prepared. elastomer.

[0074]

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com