Three-section cloth pulling and spreading machine

A braiding machine and frame technology, applied in textile and papermaking, fabric surface trimming, fabric elongation, etc., can solve problems such as inaccurate width, so as to overcome inaccurate width, improve yield, reduce The effect of cutting cloth consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] In the following, the present invention will be further described through embodiments with reference to the drawings:

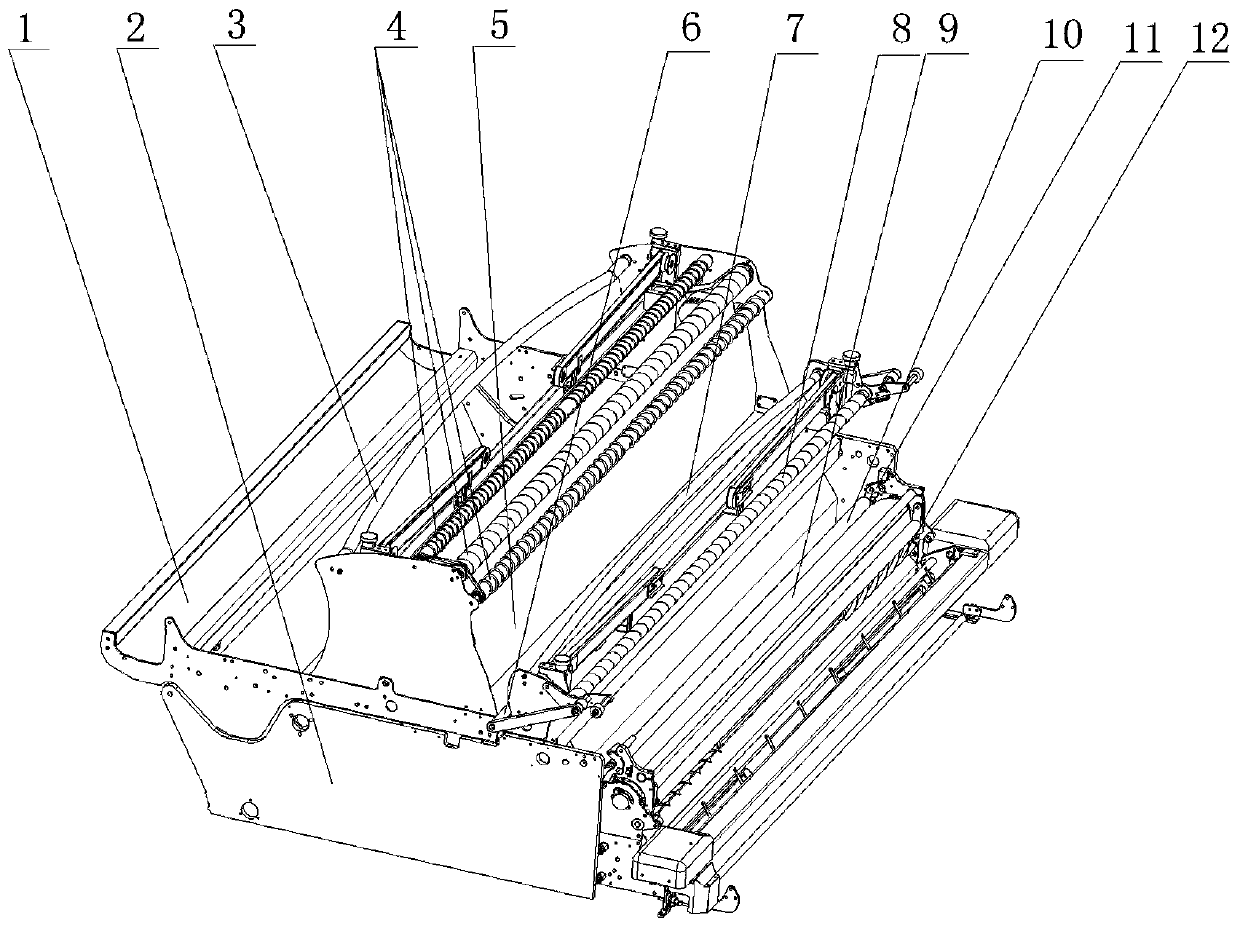

[0008] Such as figure 1 As shown, a three-stage pull cloth machine of the present invention includes a frame 2, a cloth bucket 1, and a cloth stretch structure. It is characterized in that the cloth structure adopts a three-stage cloth stretch structure. The first section of the cloth stretch structure It is composed of an arc-shaped front finishing spreading tube 3 arched upwards in the middle and three unwinding wheels 4, the above three unwinding wheels 4 are driven by a belt pulley synchronously, the second section of the spreading structure includes the unwinding The cloth groove 5, the pressure roller 6 that swings in the cloth disentanglement groove 5, an arc-shaped rear finishing spreading tube 7 and the front column roller 8 arched upward in the middle, the third section of the cloth structure includes the installation on the horse head The seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com