Replaceable concrete-filled steel tube encased ECC (engineered cementitious composite) combined anti-collision pile

A technology of steel pipe concrete and anti-collision piles, which is applied in the direction of climate change adaptation, roads, road safety devices, etc. It can solve the problems of durability, self-repair, easy separation of internal and external structures, and brittle damage of FRP, etc., so as to reduce vehicle damage , to achieve anti-collision effect, improve the effect of impact resistance and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the drawings and embodiments, which is an explanation of the present invention, not a limitation.

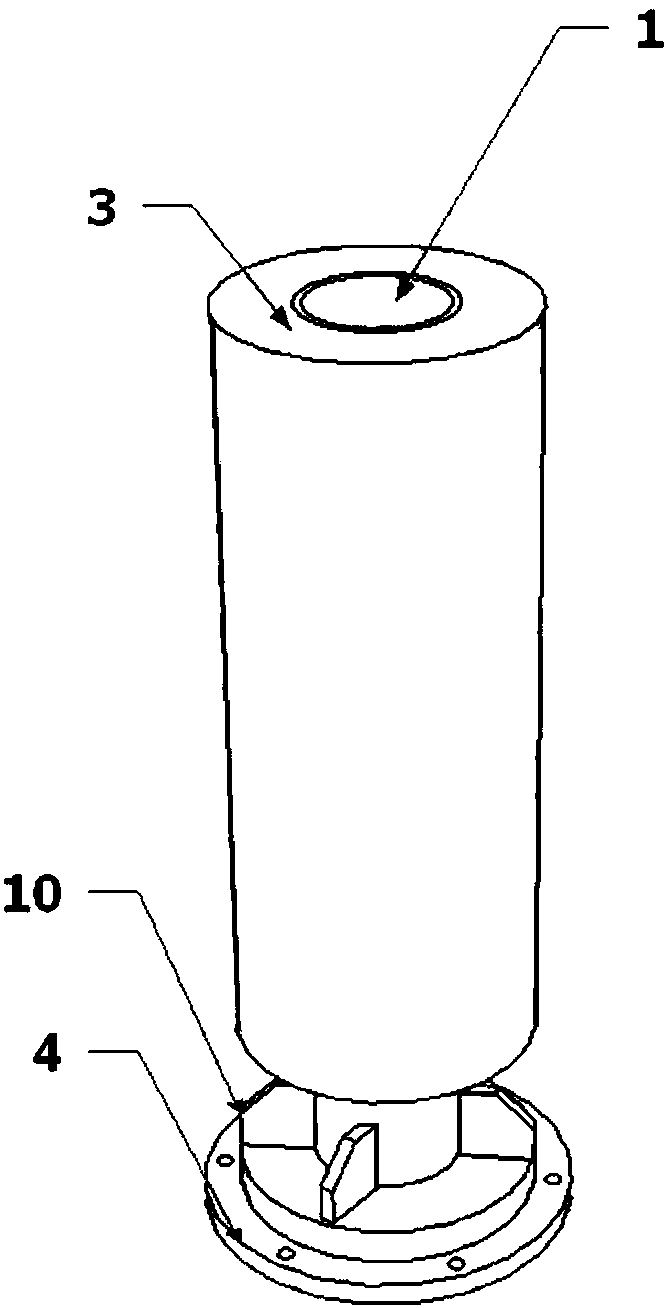

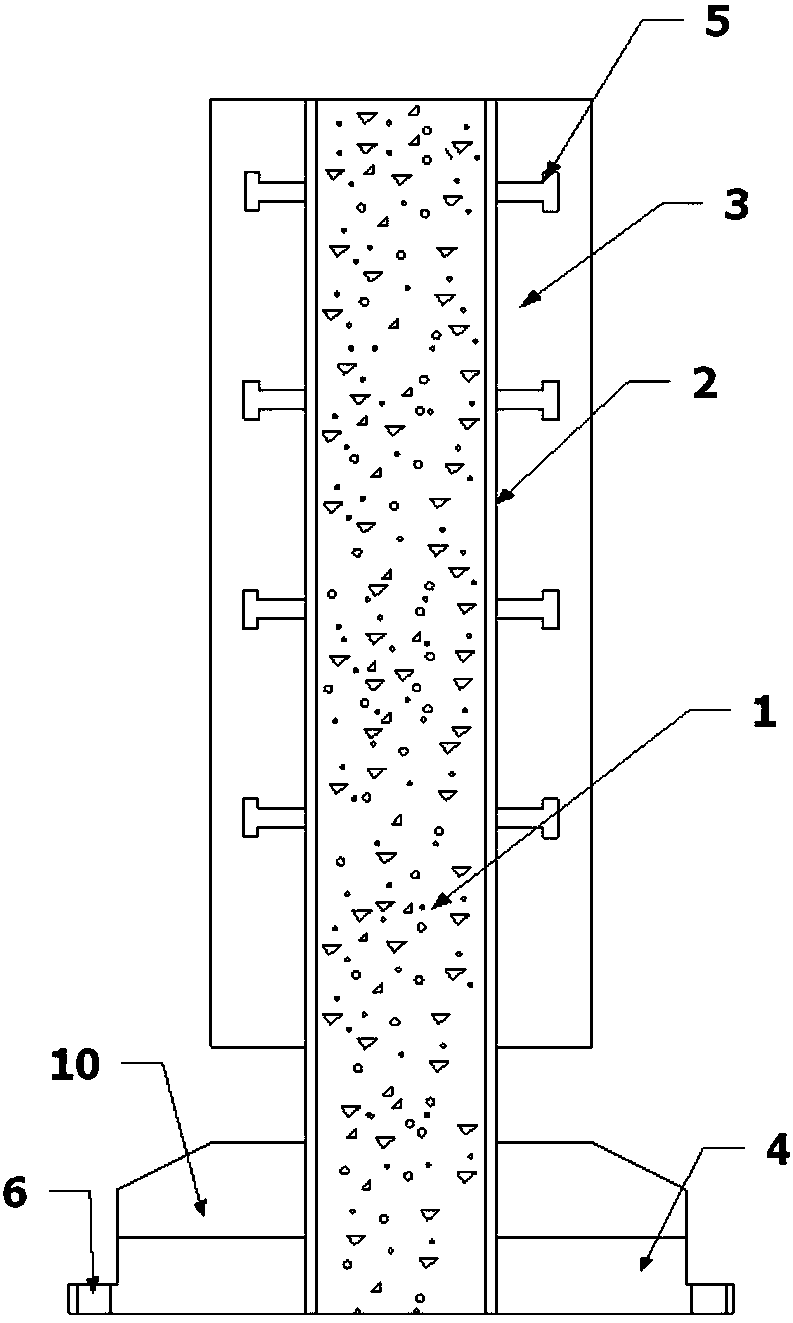

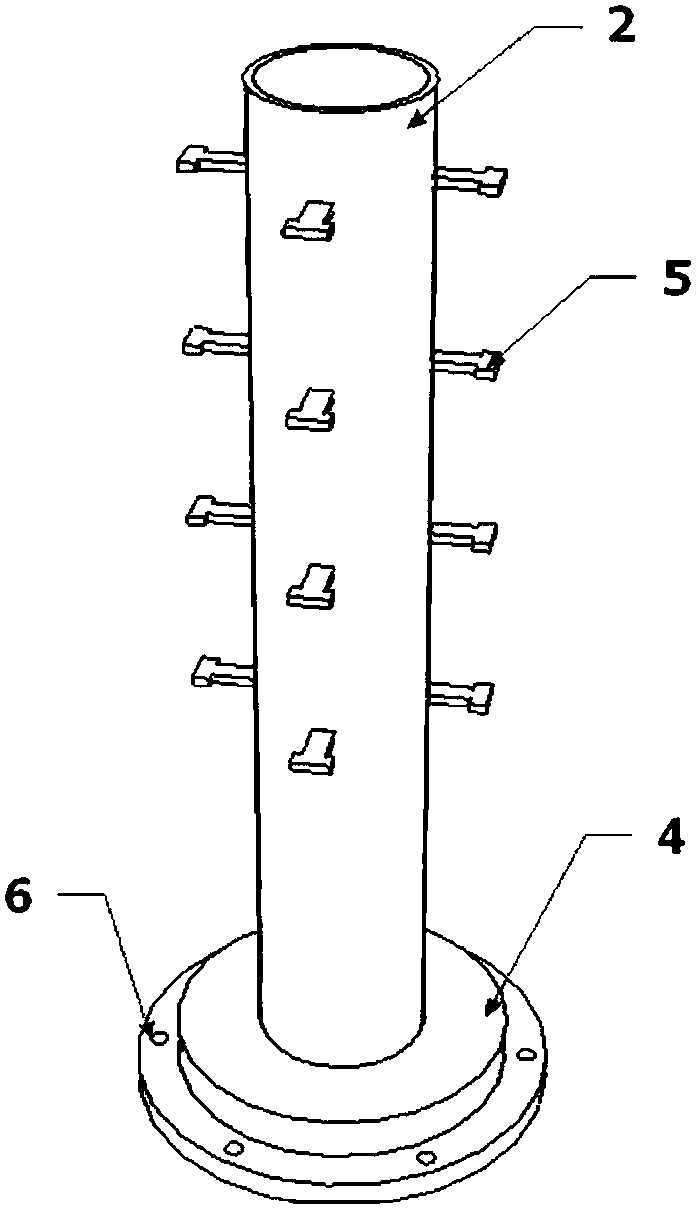

[0029] See Figure 1 ~ Figure 5 , The present invention provides a replaceable steel tube concrete-wrapped ECC composite anti-collision pile. Each anti-collision pile includes a high-strength concrete core 1, a steel tube 2 and an external ECC pouring layer 3 from the core area, wherein the high-strength concrete core 1 is formed by the inner wall of the steel tube 2 as a template, and is formed by pouring high-strength concrete (generally called high-strength concrete with a strength grade of C60 and above), so that the high-strength concrete column core 1 and the steel tube 2 form a kind of Higher-strength concrete pile structure (called concrete-filled steel tube pile). The bottom of the steel pipe 2 is inserted into the flange 4, and the steel pipe 2 and the flange 4 are connected by welding. In o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com