Novel ultrasonic clutch

A clutch and ultrasonic technology, applied in the direction of clutches, electric clutches, non-mechanical drive clutches, etc., can solve the problems of difficult automation, slow response speed, unstable operation, etc., and achieve simple and compact structure, strong carrying capacity and flexible operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

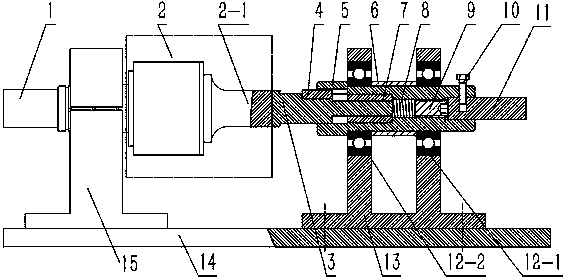

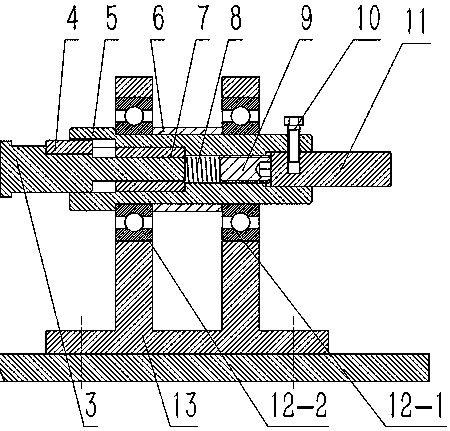

[0019] like figure 1 As shown, a new type of ultrasonic clutch includes a drive shaft (1), an ultrasonic vibration mechanism (2), a transducer (2-1), a driven shaft (3), a C-type common flat key (4), a driven Shaft sleeve (5), positioning sleeve (6), linear bearing (7), preload spring (8), preload bolt (9), rolling bearing (12), bolt (10), output shaft (11). The supporting device includes a bearing support (13) (15) and a base (14); the ultrasonic clutch and the driven assembly are fixed on the base (14) through the bearing seat (15) (13), and the replacement The three coaxial assemblies of the energy device (2-1), the driven shaft (5), and the output shaft (11).

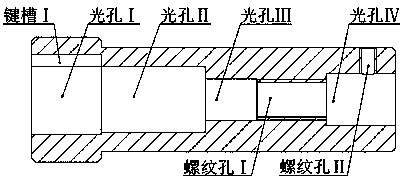

[0020] In order to ensure that the driven shaft moves axially along the driven shaft sleeve under the action of pretightening force and ultrasonic suspension force during operation, the linear bearing (7) is installed in light hole II with interference fit; the driven shaft (3) Installed coaxially with the driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com