Auxiliary machine cooling water system arranged at high position

An auxiliary cooling water and cooling water pump technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the problems of increased risk of system operation, high pressure level, and difficulty in purchasing, and achieves improved cooling effect, The effect of reducing design pressure and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

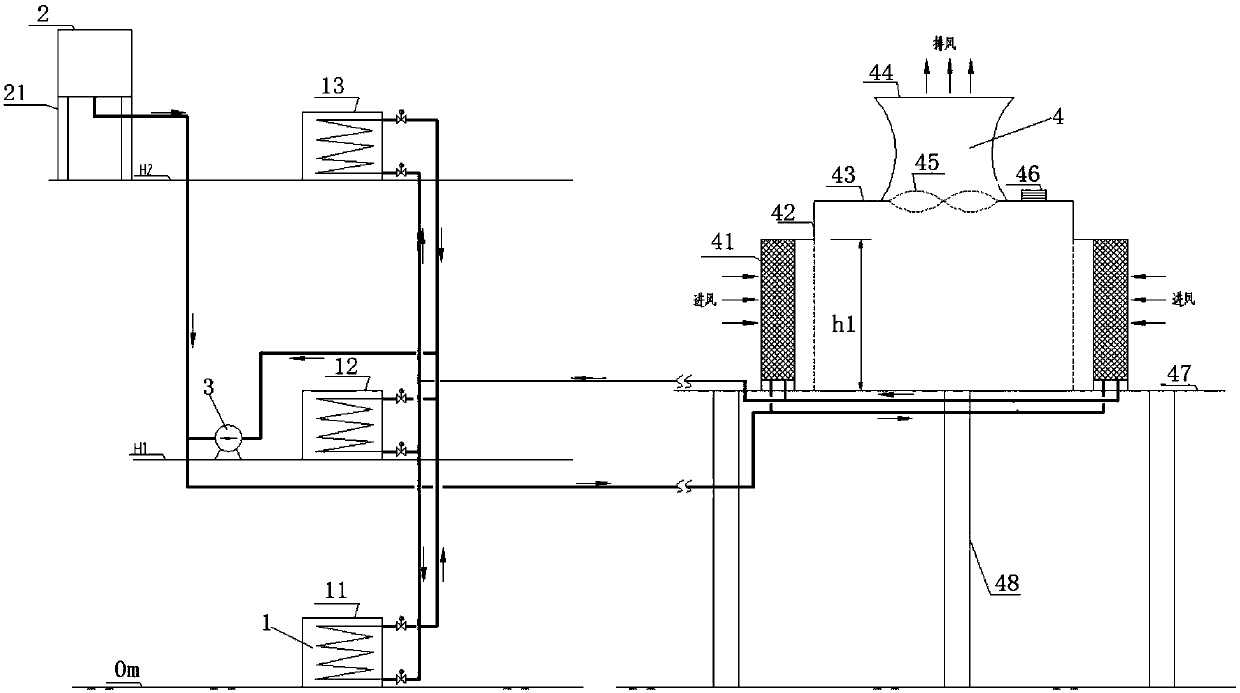

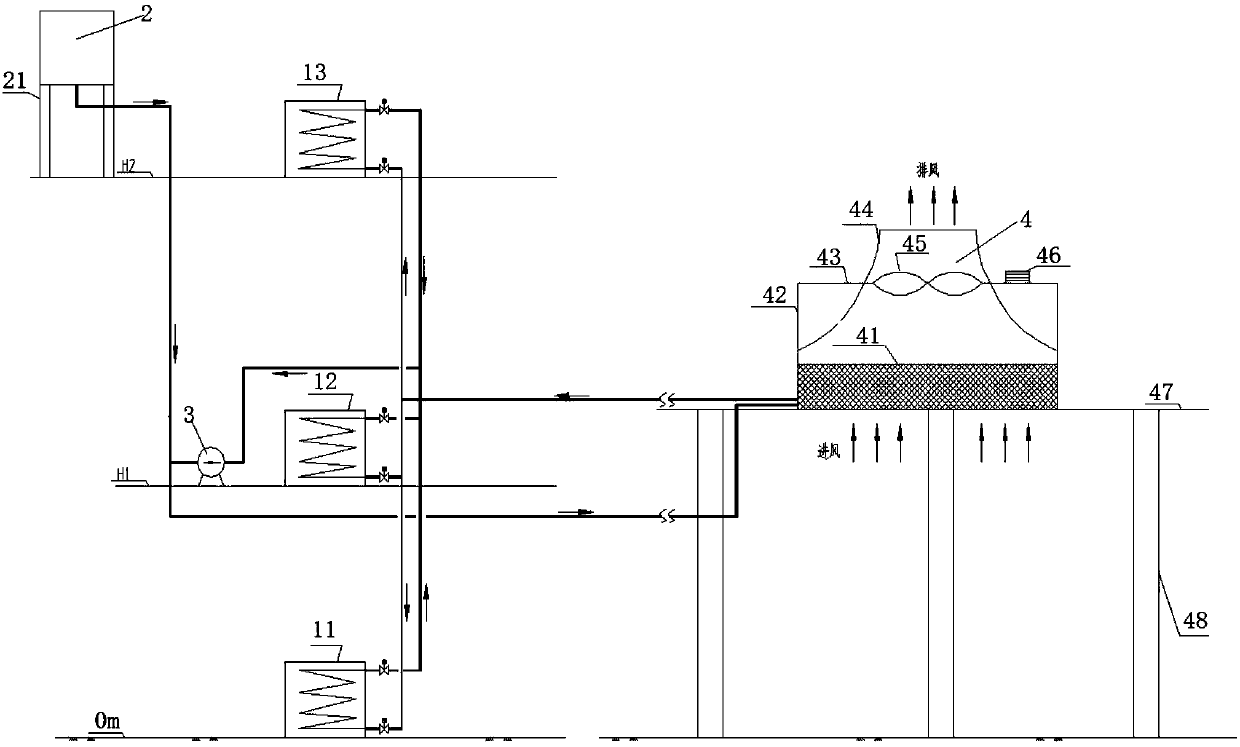

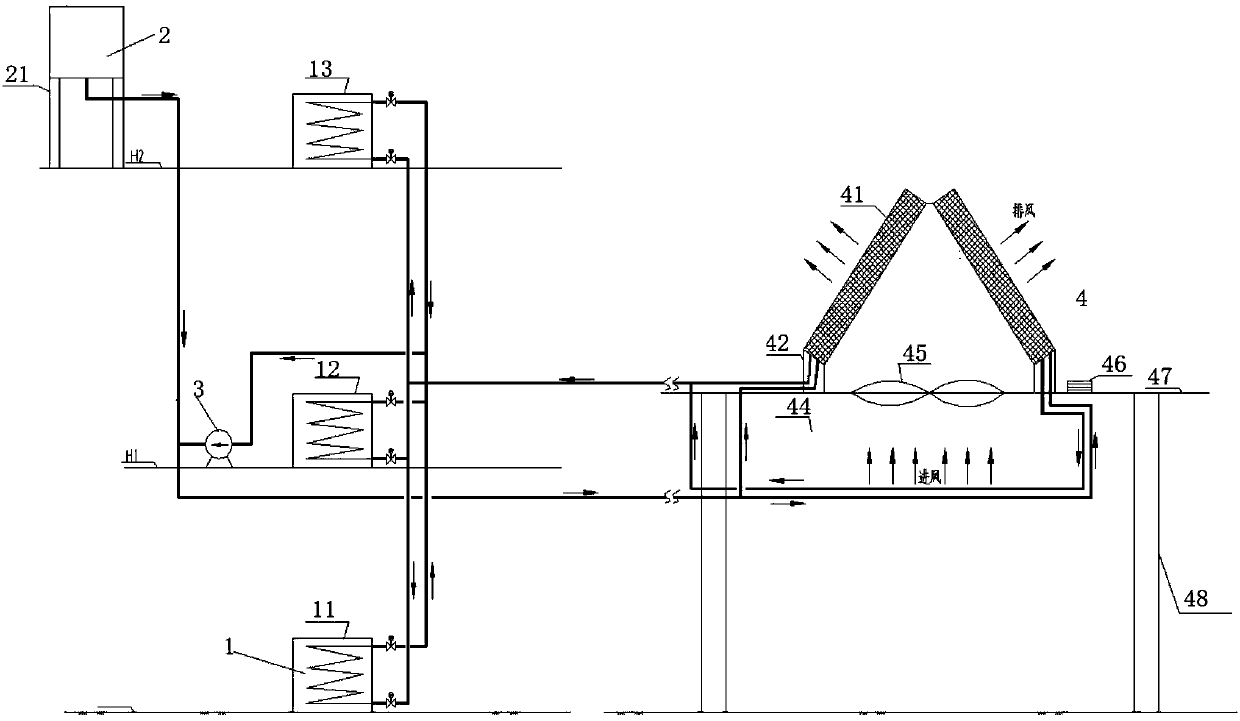

[0021] In the present invention, the auxiliary machine cooling water pump 3 is arranged on a certain floor in the middle of the turbine house (determined by calculation), the high-level water tank 2 is arranged on the 65m floor, and the auxiliary machine dry cooling tower 4 is arranged at a high position, that is, it is arranged on the air-cooling platform 47 or the roof of the turbine house. The layout height is about 25m to 65m; the auxiliary cooling water pump 3 is installed on a certain floor of the turbine room, the outlet pipe of the auxiliary cooling water pump 3 is connected to the auxiliary cooling tower 4 and the high water tank 2, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap