Multi-blade grating control system based on field bus and high-speed differential serial communication

A field bus, high-speed differential technology, applied in general control systems, control/regulation systems, transmission systems, etc., can solve problems that affect system reliability, meet real-time control requirements, and reduce the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

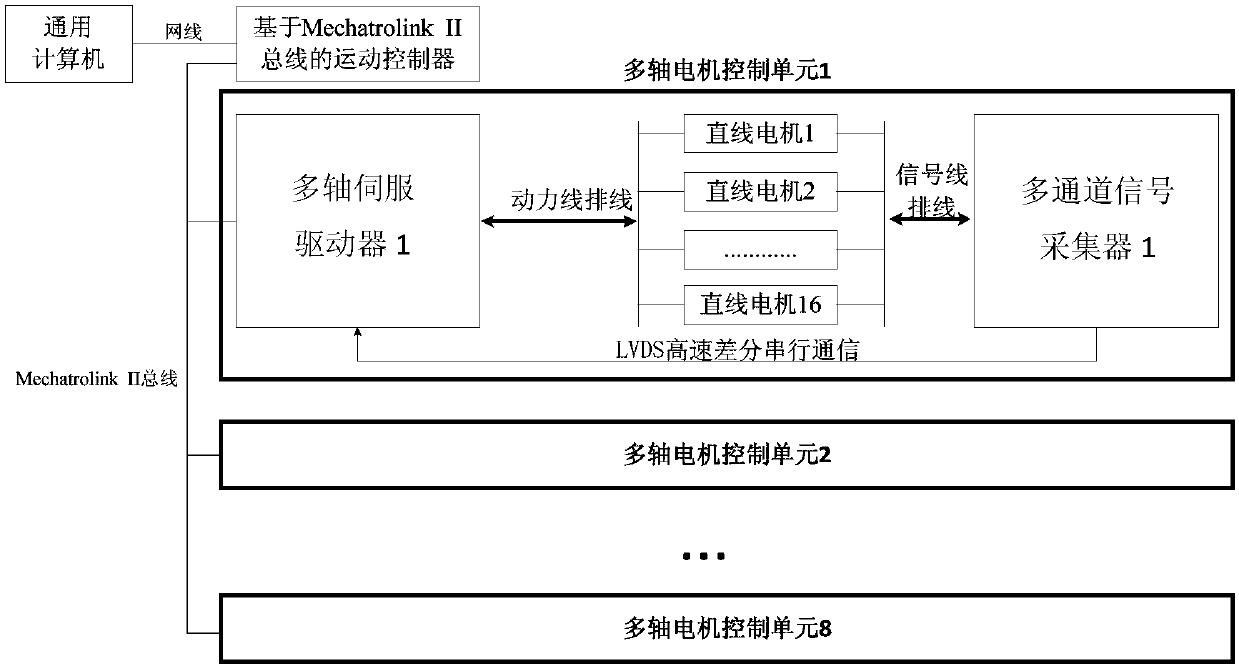

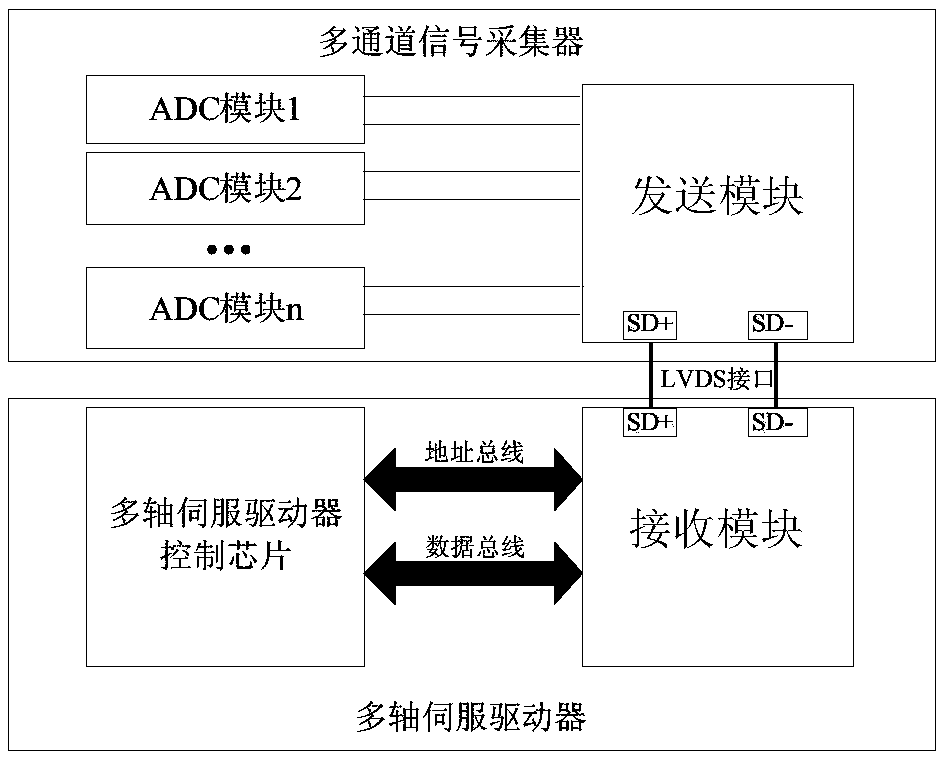

[0028] This embodiment relates to a multi-leaf grating (MLC) control system based on field bus and high-speed serial bus, the overall structure is as follows figure 1 As shown, it includes a general-purpose computer (with input devices such as keyboard and mouse), a motion controller based on the Mechatrolink II bus (made by commercially available products or conventional techniques in the art) and 8 multi-axis motor control units (the multi-axis The number of control units can be set according to the number of blades of the actual MLC); each multi-axis motor control unit includes n (the maximum value of n is 16, n=16 in this embodiment) linear motors (every 1 linear motor A motor array composed of a corresponding multi-leaf grating blade), a multi-channel signal collector and a multi-axis servo driver each equipped with a low-voltage differential signal (LVDS) interface; among them, the movement based on the Mechatrolink II bus The network port of the controller is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com