Industrial control system fault location method

A technology for industrial control systems and fault location, applied in general control systems, control/regulation systems, test/monitoring control systems, etc., to achieve the effects of reduced sampling time, high-speed computing capabilities, and large storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0018] Implementation mode 1: 20 key measuring points, sampling once every 50ms, archived instances generated in 4S, and so on.

[0019] 1. On the PLC, add 20 new data record data blocks, namely DB1001, DB1002, ..., DB1020, which are used for data record when recording is interrupted. Add data cache data block DB900, write the data of all channels into the data block in the form of a data block. Defined in advance, in the format recognized by WINCC, used as the data buffer sent by SFB37 to WINCC.

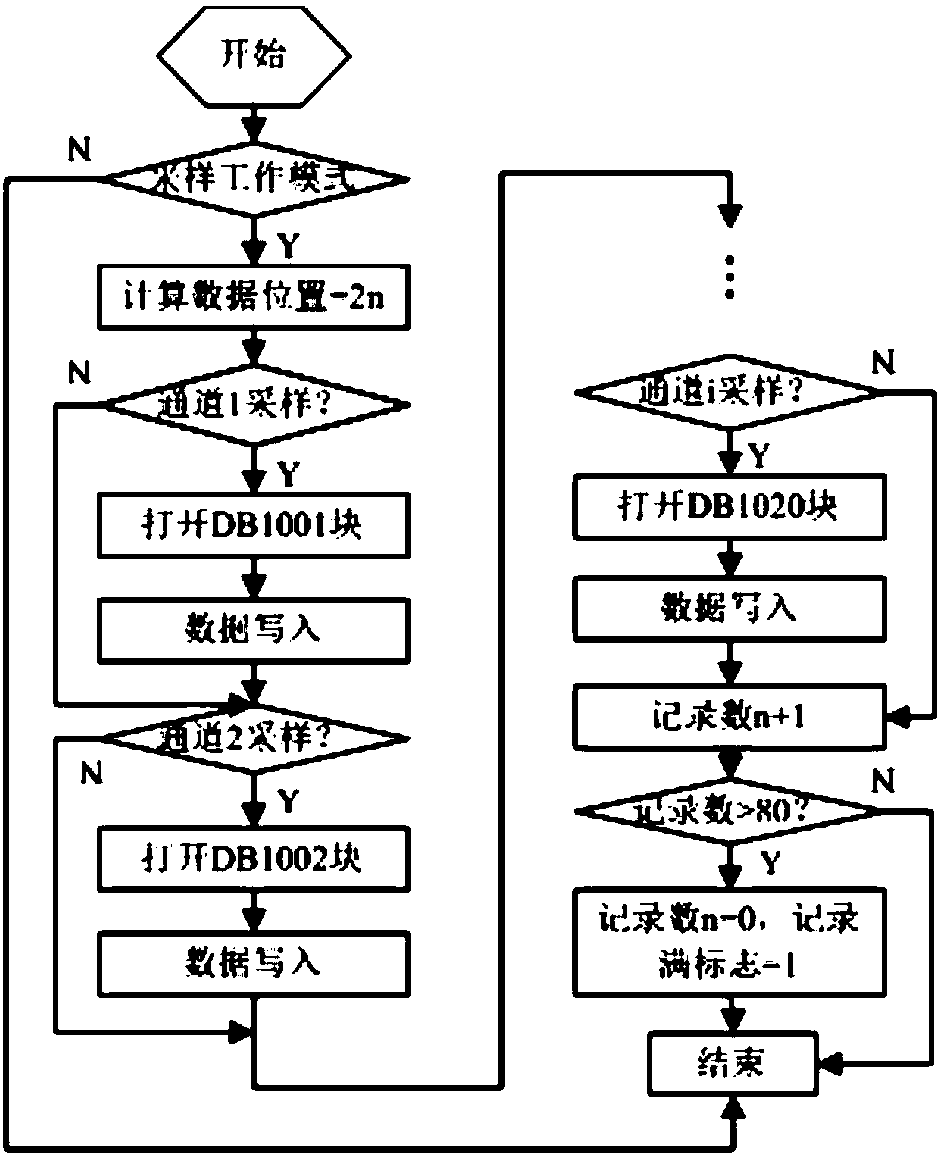

[0020] 2. In OB35, set the interrupt time to 0.05S. In the sampling mode, the program regularly writes data into the channel record data block. The program is as follows figure 1 shown.

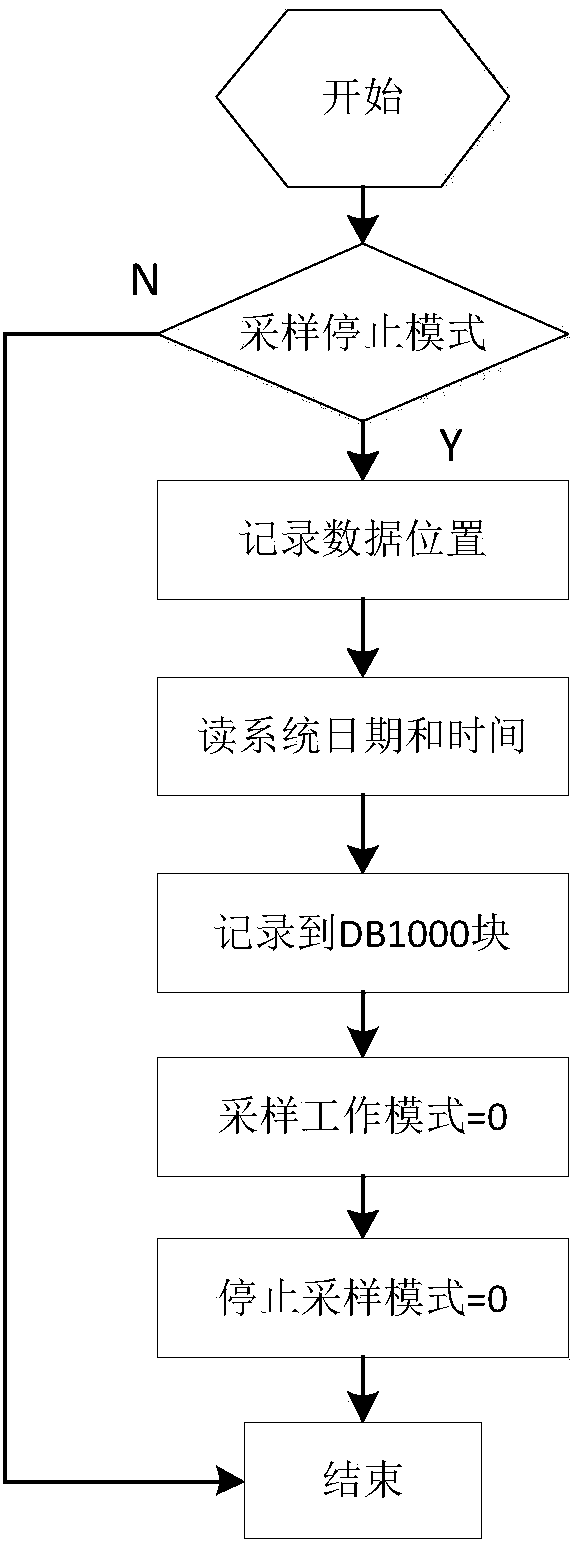

[0021] 3. In the sampling stop mode, the refresh of the data is stopped, the stop time is recorded, and the data before the failure occurs is retained. Procedure such as figure 2 shown.

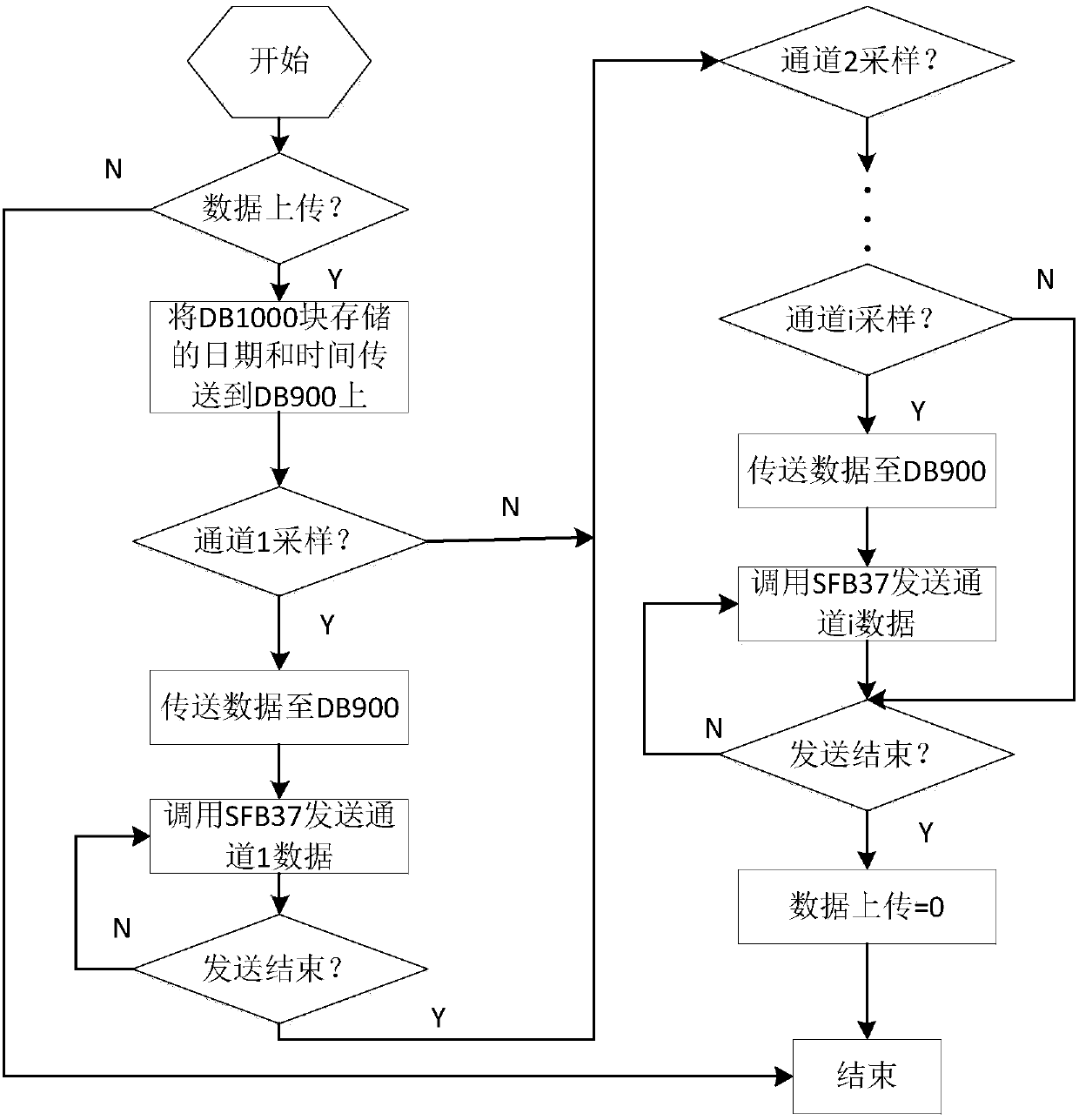

[0022] 4. When the data is uploaded, the PLC collects the data into the data cache data block DB900, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com