Dual-mode dielectric filter

A dielectric filter and dielectric resonator technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of inability to guarantee through hole accuracy and diameter accuracy, affecting the consistency of mass production, and lack of ductility. The effect of commissioning time, reducing size, reducing assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

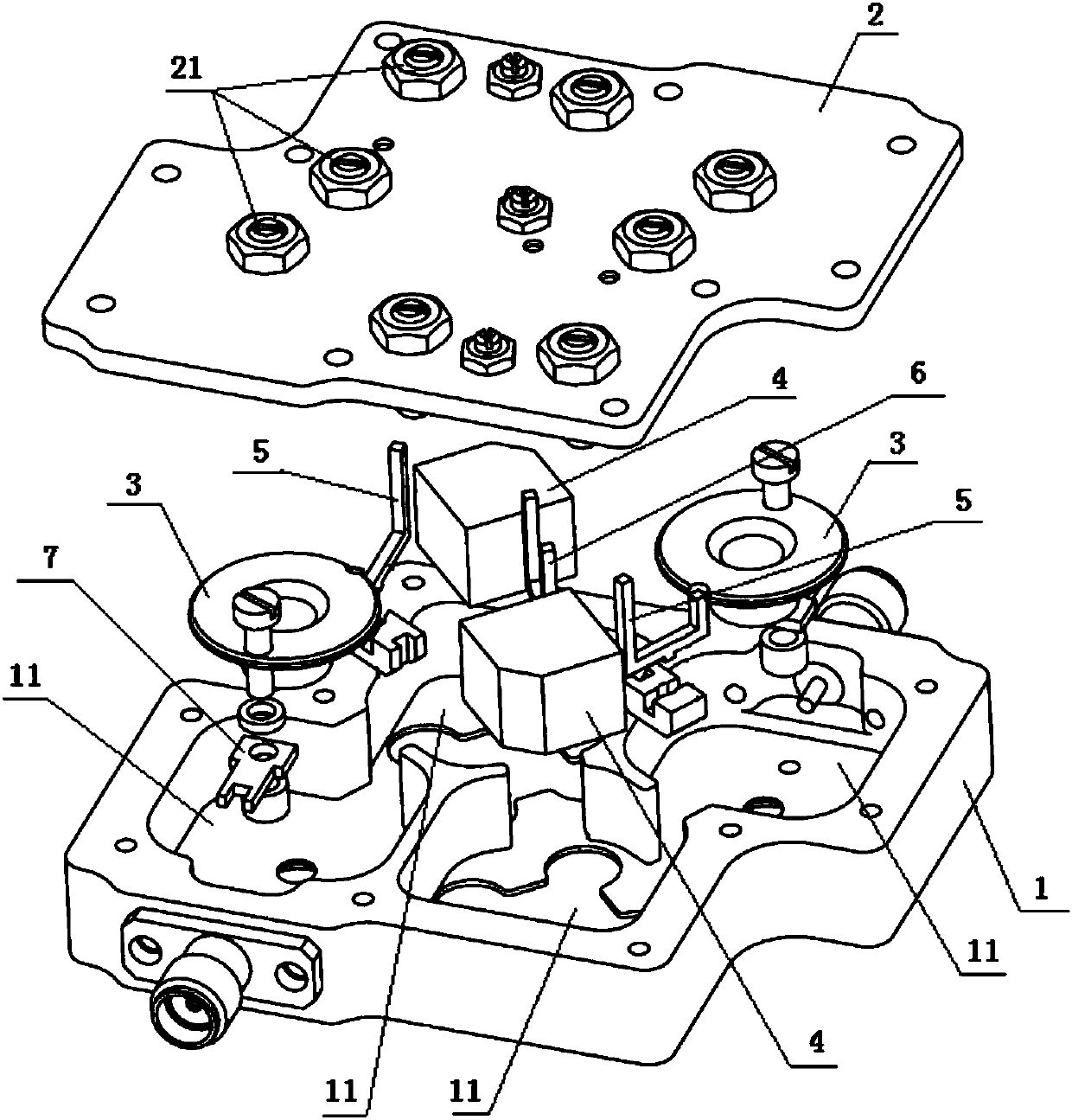

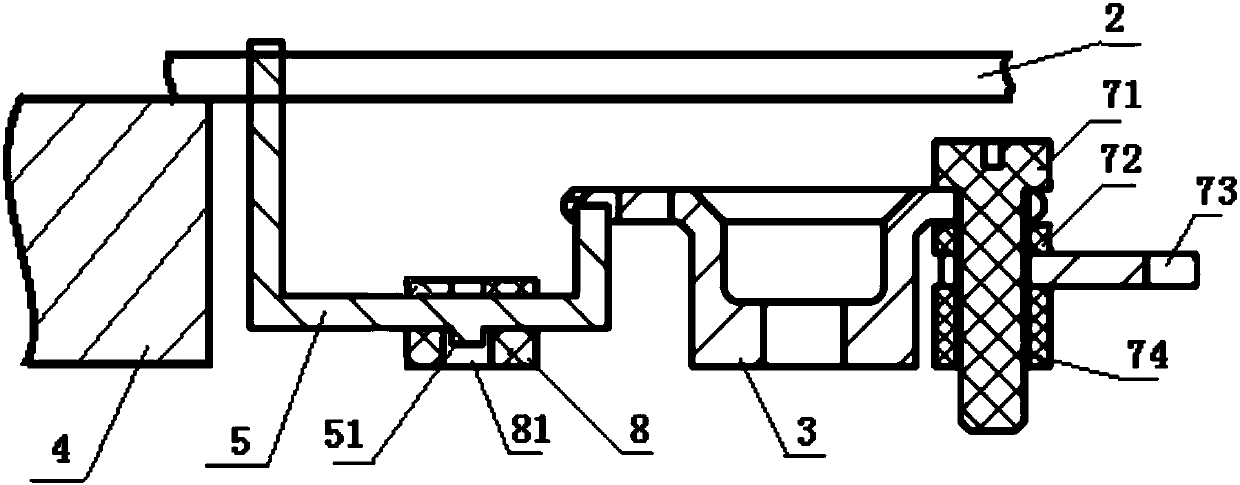

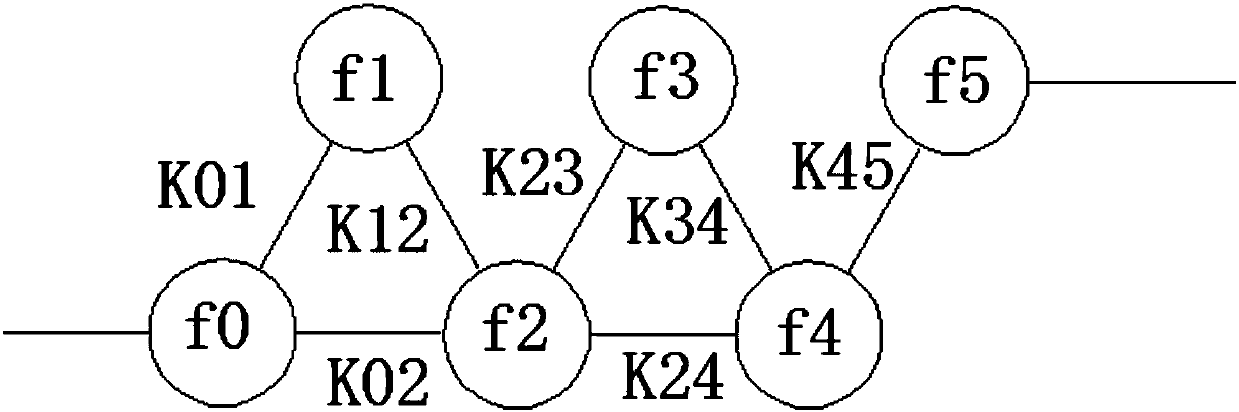

[0025] Such as figure 1 As shown, a dual-mode dielectric filter of the present invention includes a cavity body 1 and a cover plate 2, and the cover plate 2 is covered on the cavity body 1, and is fixedly connected by means of welding or crimping. Several inner cavities 11 are provided in the cavity 1, and in two adjacent inner cavities 11, a metal resonator 3 capable of generating a resonant frequency is provided in one of the inner cavities 11, and a metal resonator 3 that can generate a resonance frequency is provided in the other inner cavity 11. The dielectric resonator 4 capable of generating two resonant frequencies, the metal resonator 3 and the dielectric resonator 4 are not in contact with the corresponding inner cavity 11 wall, and the upper surface and the lower surface of the cover plate 2 are fixed by welding or crimping, etc. co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com