An upper sealing cover for a cable protection tube

A cable protection tube and cable technology, applied in electrical components and other directions, can solve the hidden dangers of personal and equipment power grid safety, protection tube rust, melting and other problems, achieve good geometric stability, prevent internal water leakage, and good waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

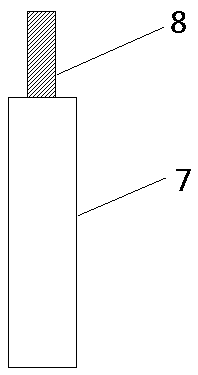

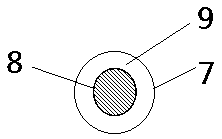

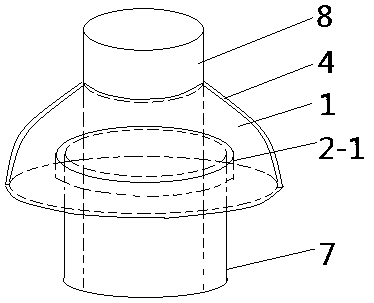

[0021] For the sealing cover on the cable protection tube of this embodiment, refer to the attached Figure 1-6 , the sealing cover on the cable protection tube of this embodiment mainly includes the following components:

[0022] Cover body 1, slot 2, upper tank body 2-1, lower tank body 2-2, cable insertion channel 3, screw cap 4, passage opening 6, cable protection tube 7, cable 8, and plugging material 9.

[0023] Connection relationship: the cover body 1 is installed at the upper seal of the cable protection tube 7, the cover body 1 is C-shaped, and the upper cover of the cover body 1 is provided with a rotary cover 4 that can rotate and seal the cover body 1, The C-shaped opening of the cover body 1 is provided with a cable insertion channel 3. The cable insertion channel 3 extends from the outer circumference of the cover body 1 to the central position of the cover body 1. The width of the cable insertion channel 3 is the same as the outer circumference of the cable 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com