High-strength PMSM (permanent magnet synchronous motor) rotor

A permanent magnet synchronous motor, high-strength technology, applied in the direction of synchronous machine parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of weakening electromagnetic performance, increasing motor air gap, and magnetic steel leakage Magnetic increase and other problems, to overcome the contradiction between structural strength and electromagnetic properties, increase structural strength, and avoid fracture phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

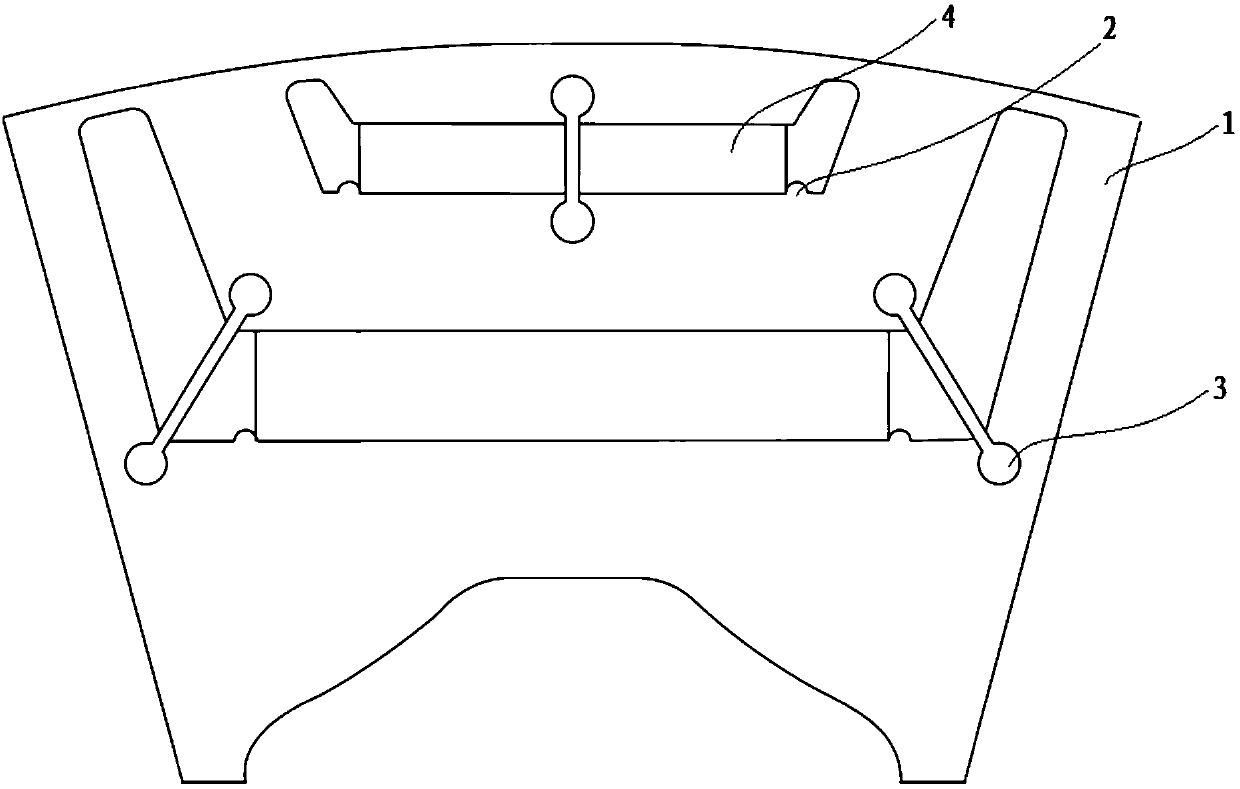

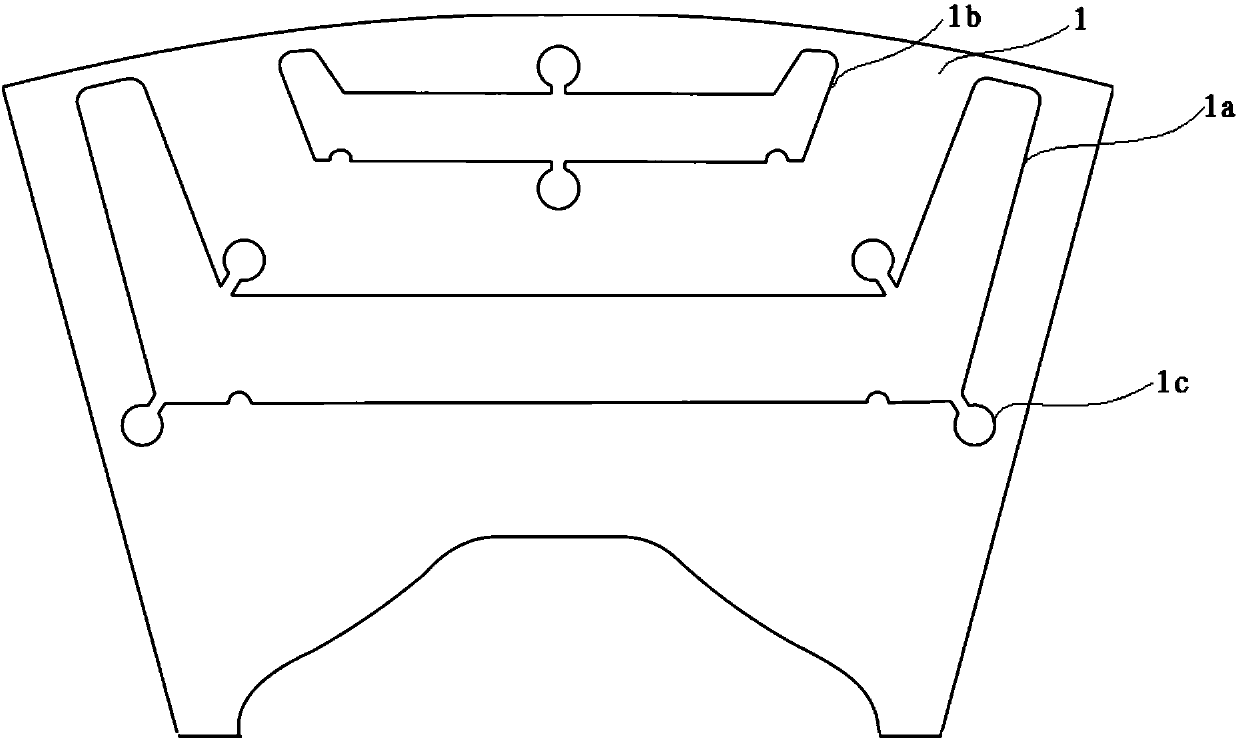

[0034] Such as figure 1 and figure 2 As shown, Embodiment 1 discloses a high-strength permanent magnet synchronous motor rotor, including: a rotor punch 1, the rotor punch 1 is in the shape of a circular sheet, and along the circumferential direction of the rotor punch 1, there are 8 sets of U Each group of U-shaped magnetic steel grooves includes two U-shaped magnetic steel grooves arranged along the radial direction of the rotor punching plate 1, which are respectively the first U-shaped magnetic steel groove 1a and the second U-shaped magnetic steel groove The U-shaped magnetic steel groove 1b, the first U-shaped magnetic steel groove 1a and the second U-shaped magnetic steel groove 1b are all symmetrical about the same radial direction of the rotor punch 1, and the U-shaped magnetic steel groove near the center of the rotor punch 1 is the first U-shaped magnetic steel groove. A U-shaped magnetic steel groove 1a, the U-shaped magnetic steel groove away from the center of ...

Embodiment 2

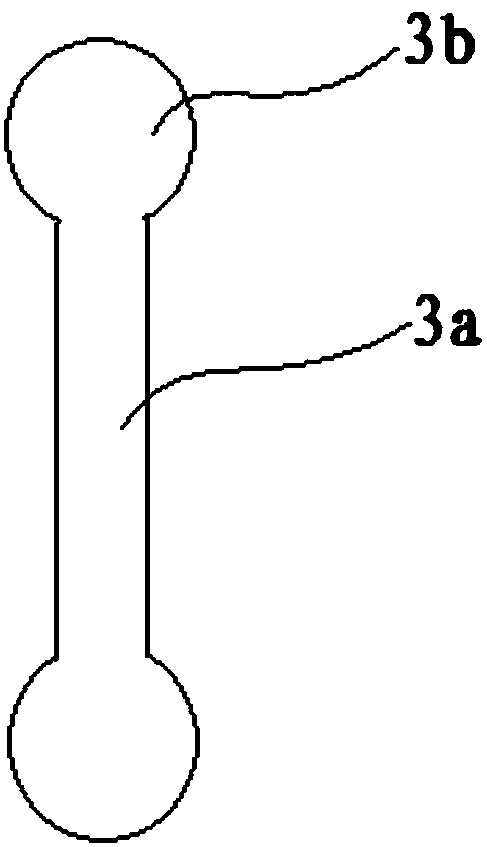

[0044] Such as figure 1 Shown, embodiment 2 is on the basis of embodiment 1, and the middle position of the second U-shaped magnetic steel groove 1b of embodiment 2 is also provided with the non-magnetic conduction across the groove width direction of the second U-shaped magnetic steel groove 1b Connecting piece 3, the connection method between the non-magnetic connecting piece 3 arranged at the second U-shaped magnetic steel slot 1b and the rotor punch 1 is the same as that of the non-magnetically conductive connecting piece at the first U-shaped magnetic steel slot 1a in Example 1 3 are connected in the same way, and the axis of the non-magnetic connecting piece 3 passes through the center of the rotor punching piece 1. And the non-magnetic connecting piece 3 in this embodiment is made of austenitic stainless steel.

[0045] In other embodiments, the non-magnetic connecting piece 3 is not limited to the location of the above embodiments 1 and 2, and can also be arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com